Round tube bending machine

A round tube and machine body technology, applied in the field of round tube arc presses, can solve problems such as difficult quality assurance, low work efficiency, and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

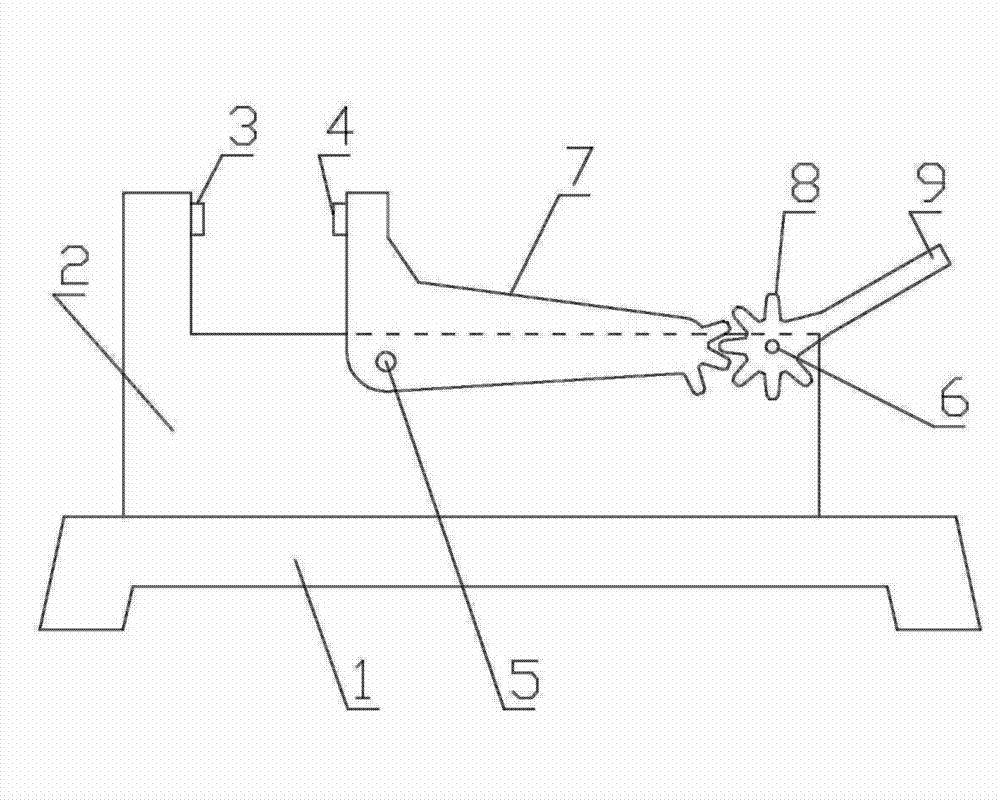

[0009] Such as figure 1 As shown, a circular tube arc pressing machine of the present invention is provided with a body 2, a force transmission arm 7, and a driving gear 8. A fixed mold 3 is provided on the protrusion on the upper part of the body 2, and the force transmission arm 7 and the body 2 are hinged on At 5 places of the power transmission shaft, the body 2 is provided with a positioning shaft 6 at an end away from the fixed mold 3, and the driving gear 8 and the body 2 are hinged at the positioning shaft 6, and the driving gear 8 is fixedly connected with a driving handle 9, so The force transmission arm 7 is a curved structure and is divided into a vertical section and a horizontal section. The upper part of the vertical section of the force transmission arm 7 is provided with a movable mold 4, and the horizontal section of the force transmission arm 7 is provided with a driving gear. 8 meshing gear teeth. The force transmission arm 7 can freely rotate around the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap