Novel hard alloy cold forging die for combined gear ring

A technology of hard alloy combined with ring gear, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve the problems of easy wear and failure of the mold surface, easy cracking, and stress concentration at the sharp corners of the teeth. , to achieve the effect of tooth shape accuracy guarantee, prolong service life, and small elastic deformation of tooth shape

Inactive Publication Date: 2012-12-05

TAICANG JIUXIN PRECISION MOLD

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional mold for forming such parts is made of high-speed steel, and the mold core part is an integral structure. Because the sharp corners of the teeth are prone to stress concentration, cracks are prone to occur in mass production

In addition, during the split-flow forming process of the boss, the surface of the mold is extremely prone to wear and failure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

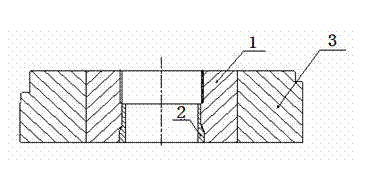

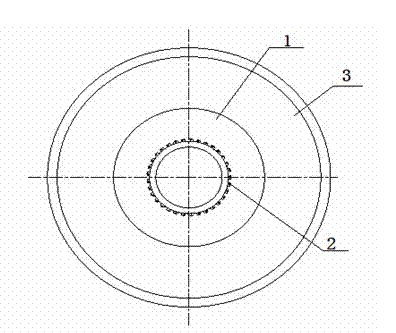

The invention discloses a novel hard alloy cold forging die for a combined gear ring. The hard alloy cold forging die comprises a tooth-shaped female die and a prestress outer ring arranged on an outer ring of the tooth-shaped female die, wherein the tooth-shaped female die has a split structure, and comprises a tooth-shaped die core and a lower die core; the tooth-shaped die core wraps the lower die core; and the prestress outer ring wraps the tooth-shaped die core. Compared with the prior art, the hard alloy cold forging die has the advantages that the tooth-shaped die core has a split structure, so that the defect that the die is cracked early due to stress concentration at a sharp corner of the die is overcome, and the service life of the die is prolonged; and the die is made of a hard alloy material, so that tooth-shaped elastic deformation is small, the tooth-shaped accuracy can be ensured, and the anti-wearing performance can also be improved greatly.

Description

technical field [0001] The invention designs a cold forging die, in particular to a cemented carbide cold forging die for a ring gear. Background technique [0002] Combined with the ring gear used in automotive transmissions, its shape is composed of a toothed part and a boss part, and has the characteristics of a hollow hub as a whole. The traditional mold for forming such parts is made of high-speed steel, and the core part is an integral structure. Since the sharp corners of the teeth are prone to stress concentration, cracks are prone to occur in mass production. In addition, during the split flow forming process of the boss, the surface of the mold is very easy to wear and fail. Contents of the invention [0003] In order to overcome the above defects, the present invention provides a long service life and wear-resistant hard alloy cold forging die for combined ring gear. [0004] In order to achieve the above purpose, the following technical solutions are adopted:...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21J13/02

Inventor 章立预马霄峰郑英俊

Owner TAICANG JIUXIN PRECISION MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com