Impact tool

A technology of impact tools and tools, which is applied in the field of impact tools, can solve problems such as complex structures, component wear, and increased manufacturing costs, and achieve the effects of improving durability and stabilizing vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

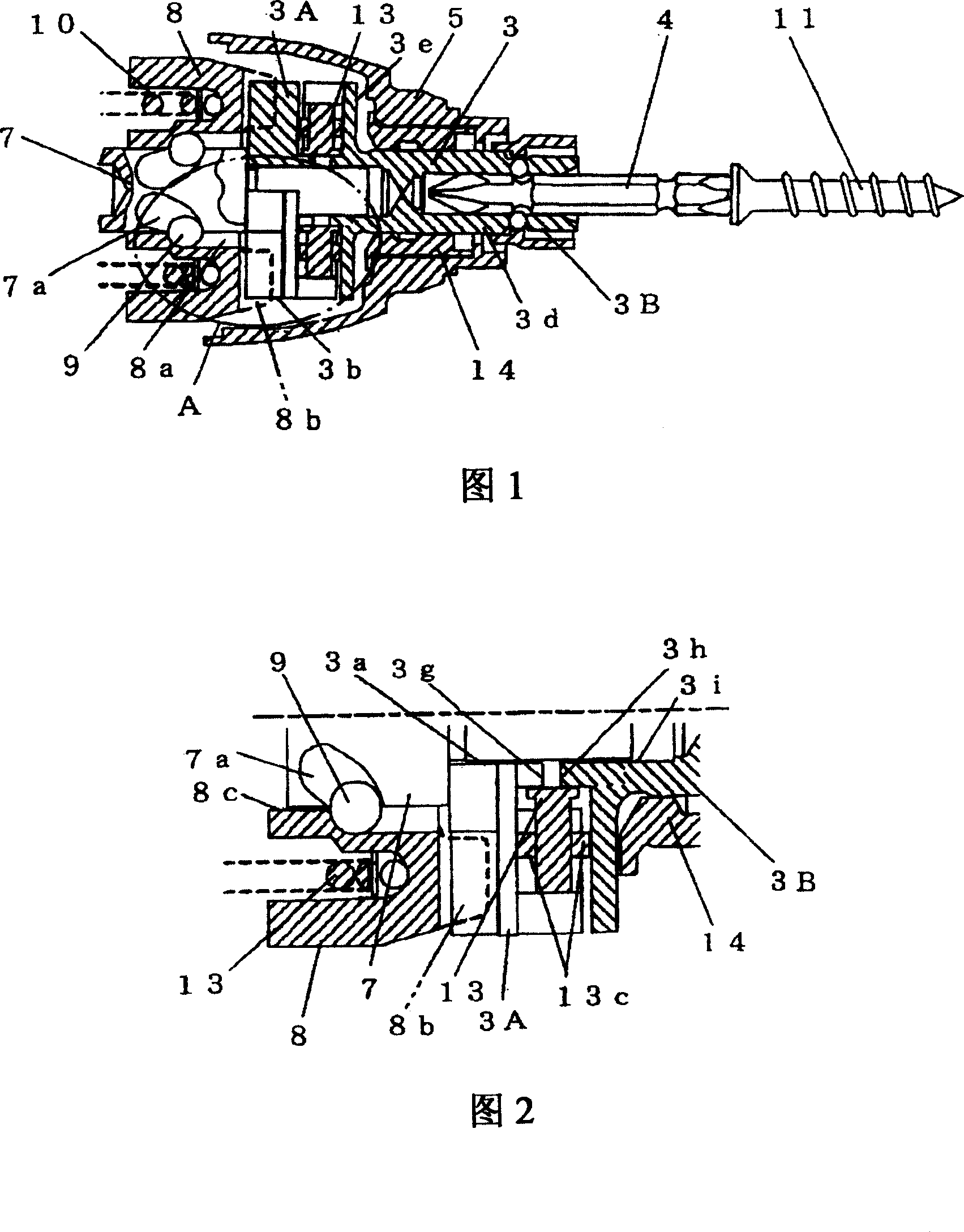

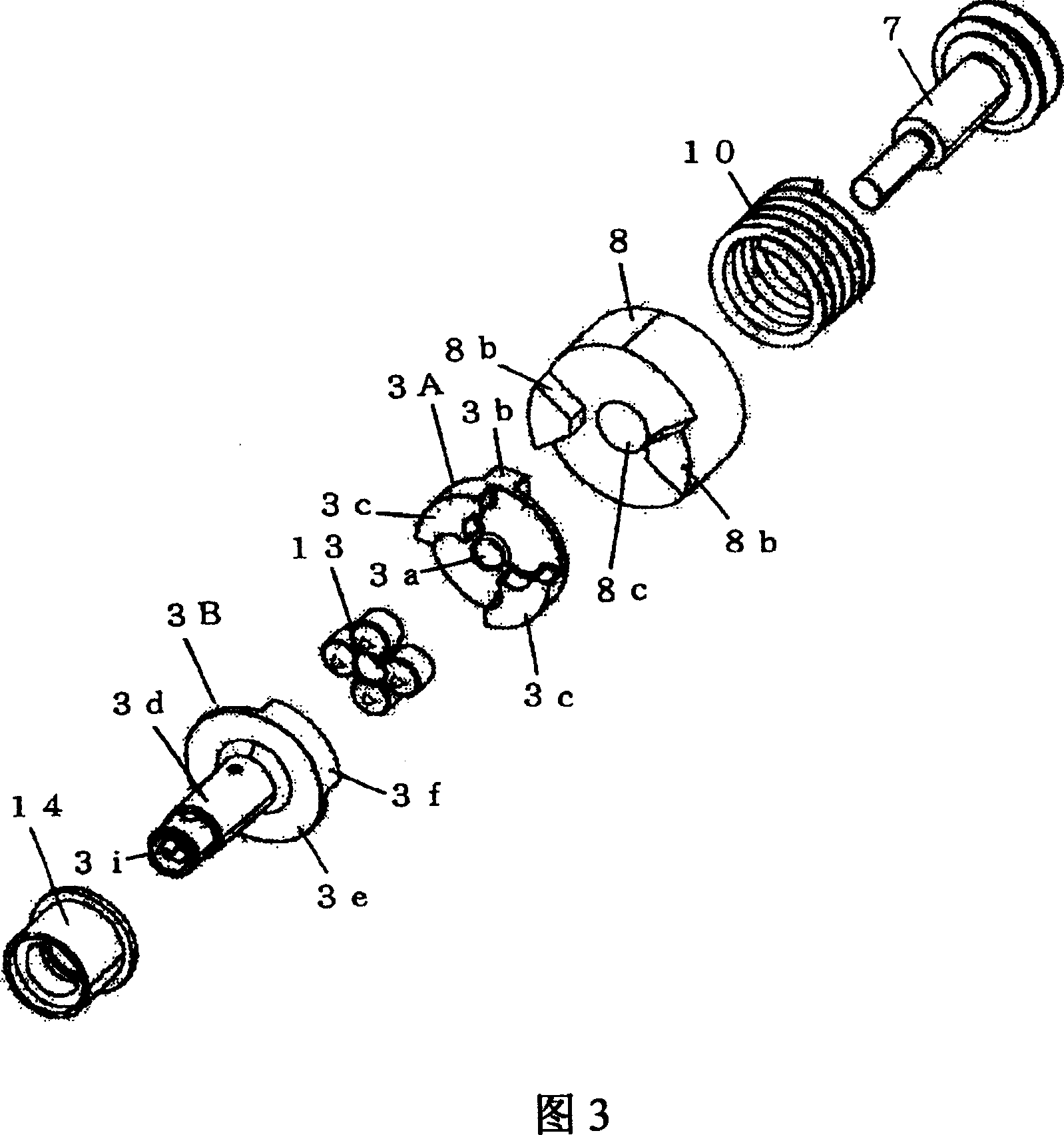

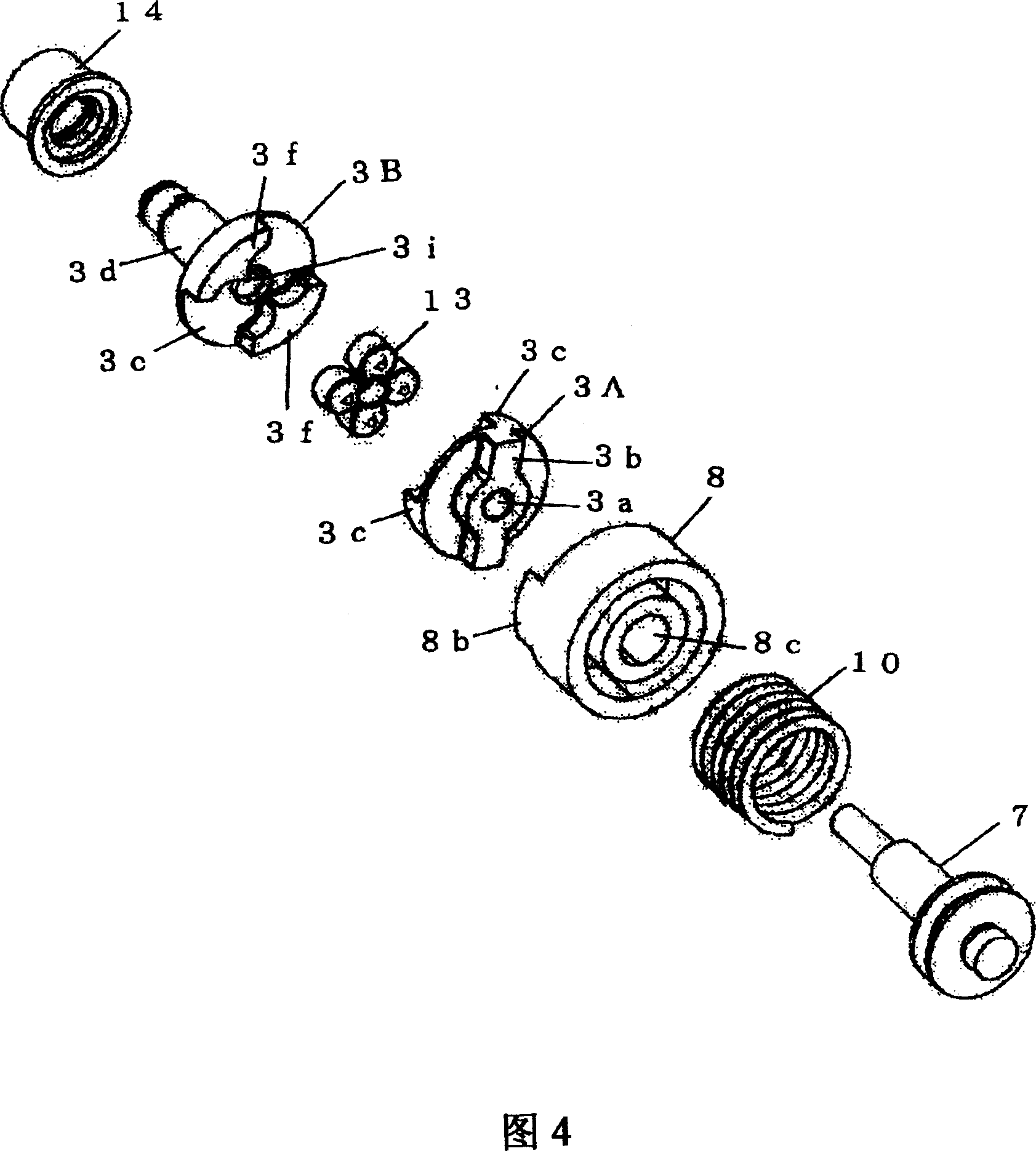

[0036] Hereinafter, embodiments of the present invention are explained with reference to the drawings.

[0037] 1 is a longitudinal section of a rotary impact mechanism unit of an impact tool according to the invention. FIG. 2 is an enlarged detailed view of part A of FIG. 1 . 3 and 4 are exploded perspective views of the rotary impact mechanism unit of the impact tool. Fig. 5 is a side sectional view of an anvil of an impact tool. FIG. 6 is a cross-sectional view taken along line B-B of FIG. 5 . FIG. 7 is a cross-sectional view taken along line C-C of FIG. 6 . Fig. 8(a) is a front view of the rubber damper. Fig. 8(b) is a side view of the rubber damper. 9(a) and 9(b) are front views for explaining the operation of the pawl of the anvil. In these figures, the same components as those shown in FIG. 10 are denoted by the same reference numerals.

[0038]The impact tool according to the present embodiment is a cordless hand-held tool having a battery pack as a power source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com