Test detecting device with safety belt height adjuster and detecting method for test detecting device

A technology of height adjuster and angle adjustment device, which is applied in the direction of measuring device, machine/structural component test, vehicle test, etc. It can solve the problem of inaccurate feedback of user strength, moving distance and operating comfort, and the test process cannot be very fast. Good control and adjustment, not good analysis of later design adjustments and other issues, to achieve the effect of improving operating comfort, convenient installation and testing, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

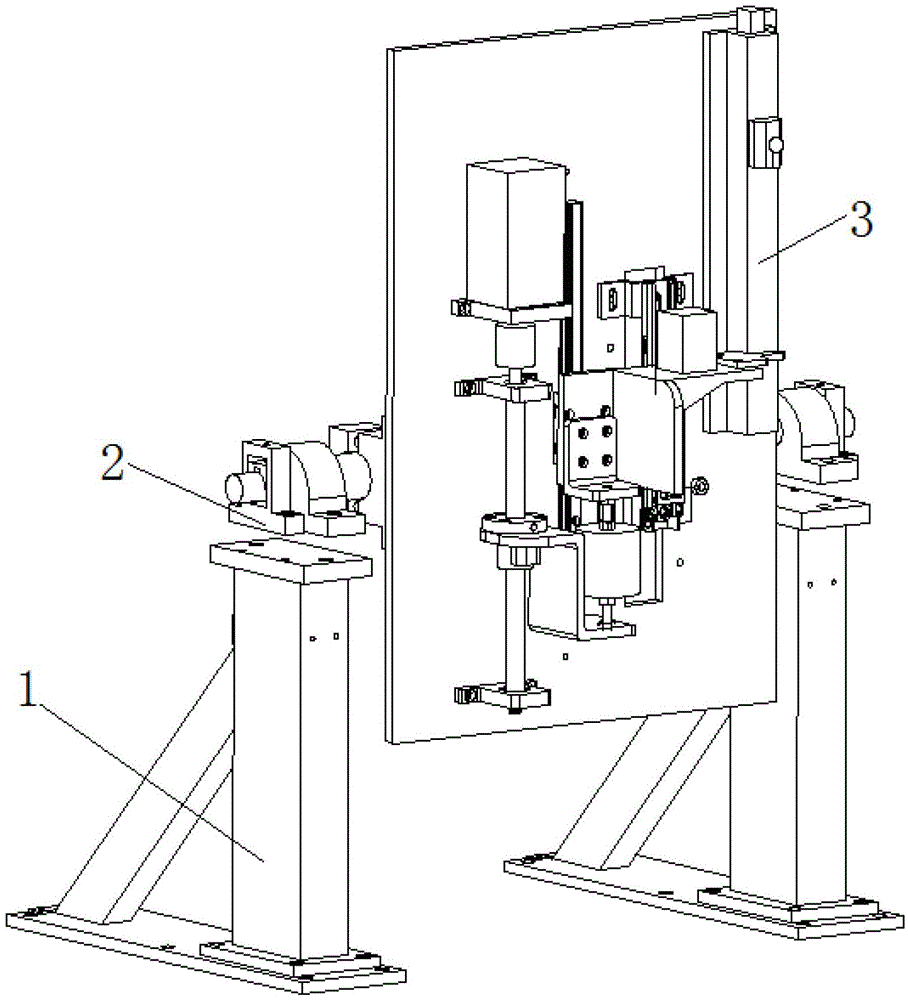

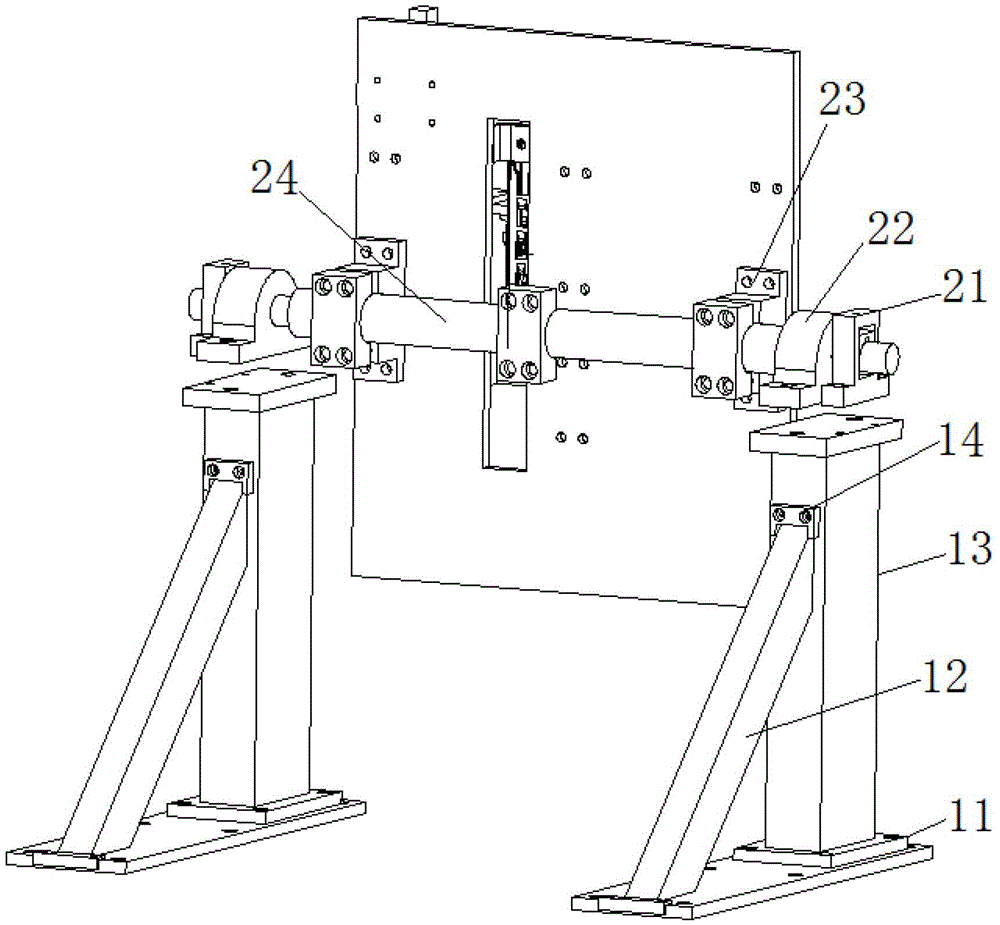

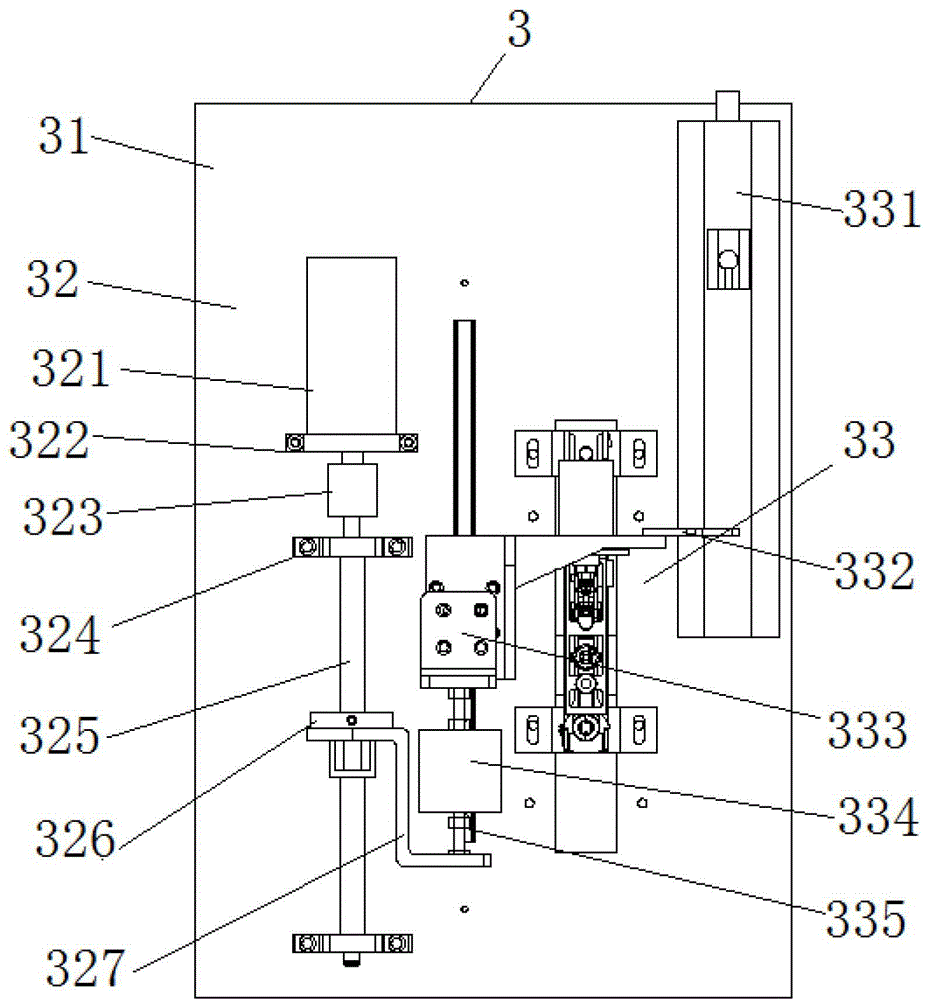

[0031] Such as Figure 1 to Figure 4 As shown, the test detection device of the safety belt height adjuster includes a test device 3, a detection sample 3310 of the safety belt height adjuster, and a sample mounting plate 31 for installing the detection sample 3310, and the detection sample 3310 is installed on the sample mounting plate 31; also includes a cylinder 3307 for pressing and unlocking the detection sample 3310; on the sample mounting plate 31, a drive unit 32 for driving the detection sample 3310 to simulate height position adjustment and a detection unit for detecting the driving force and displacement of the detection sample 3310 are provided 33; the drive unit 32 includes a drive motor 321, a ball screw 325 connected to the output shaft of the drive motor 321 and a lead screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com