Apparatus For Dispensing A Pressurised Liquid

A technology of pressurized liquid and liquid, which is applied in the field of equipment for pressurizing and distributing multiple liquids, which can solve the problems of unusable devices and achieve the effect of improving distribution speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

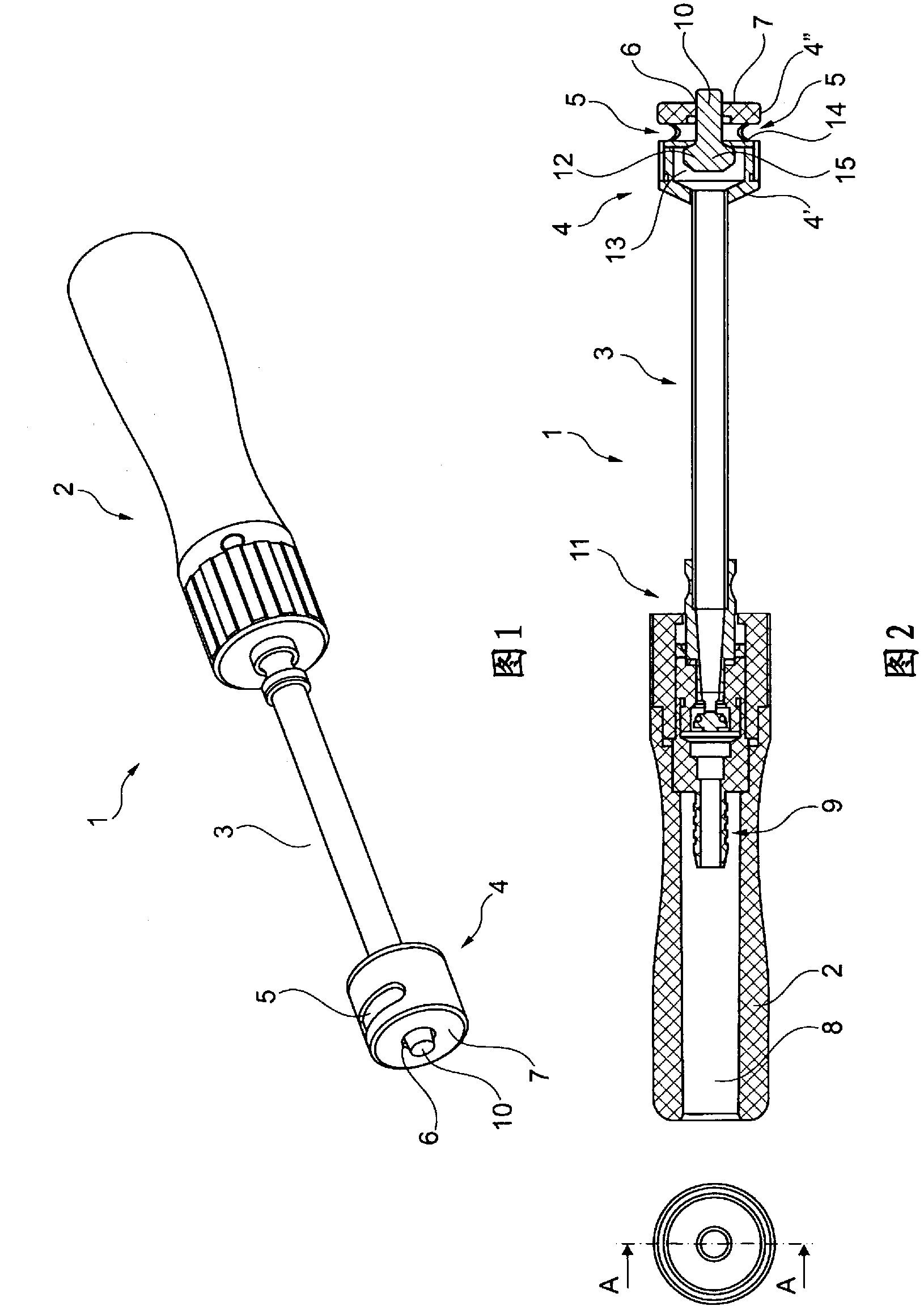

[0049] figure 1 A preferred embodiment of the invention is shown in . The device 1 comprises a handle 2 , a stem 3 and an outlet body 4 .

[0050] The handle is preferably made of plastic, injection molded, and of a size that is comfortable in use, but other than these requirements, the handle may be made of any material and in any shape or form as the user sees fit.

[0051] The stem 3 has such a length that the outlet body 4 can be brought into contact with the bottom of the can or glass without submerging the whole device in the can or the dispensed liquid. The connection between the handle and the rod is preferably detachable, as will be referred to figure 2 It is stated, but it is also conceivable that a non-separable rod could be used in conjunction with the handle.

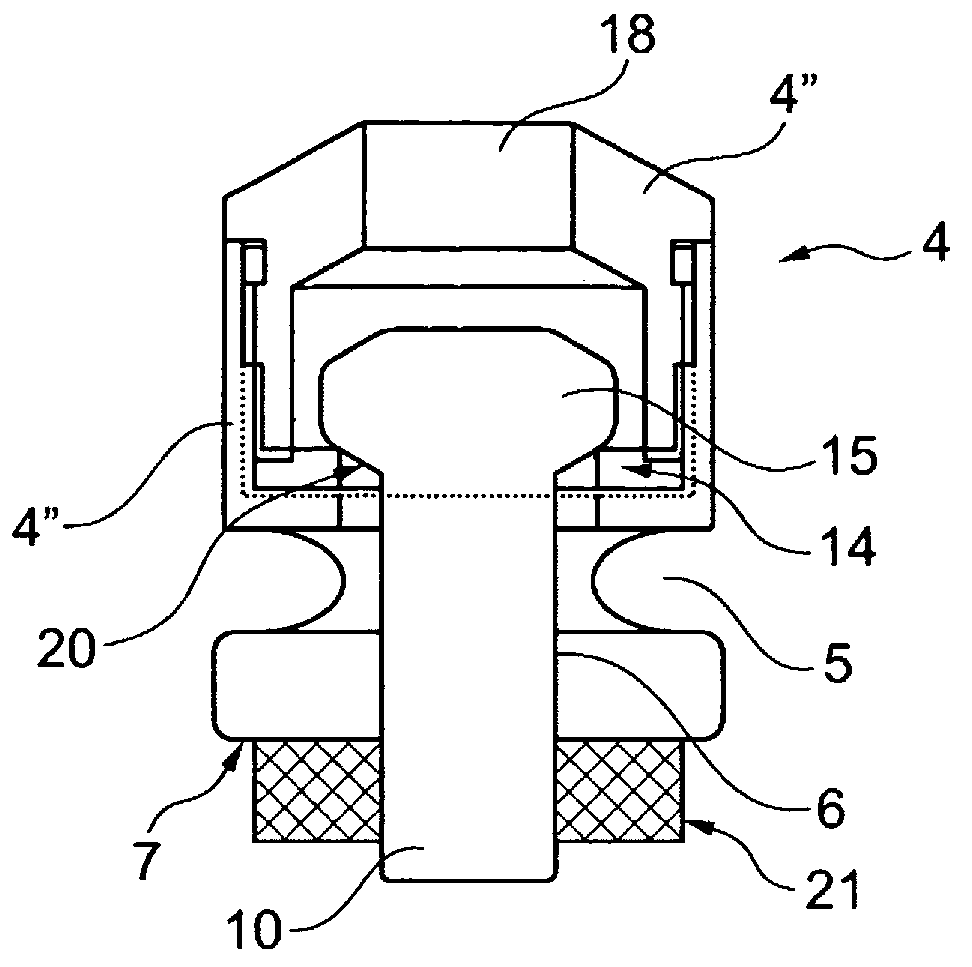

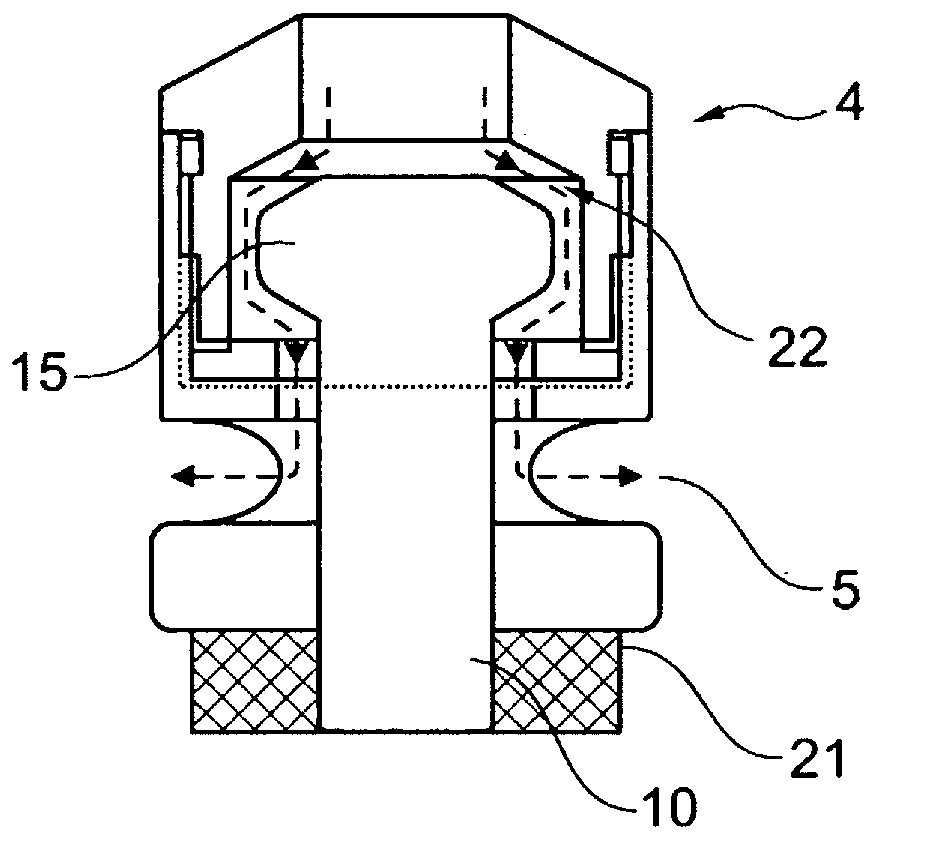

[0052] The outlet body 4 is provided with an outlet opening 5 and an opening 6 in the bottom surface 7 of the outlet body 4 . A stem 10 of a valve body (not shown) protrudes outwards through an opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com