Spiral sheer reinforcement and bar arrangement of slab steel bars using same

A technology of spiral steel bars and reinforcements, applied to structural elements, floor slabs, building components, etc., can solve the problems of complex production of shear reinforcements, achieve simple production and supply, reduce the number of steel bars, and reduce the effect of welding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

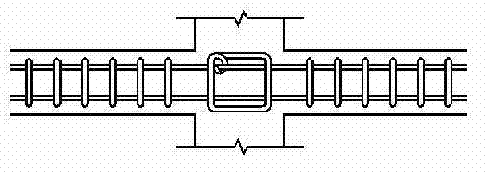

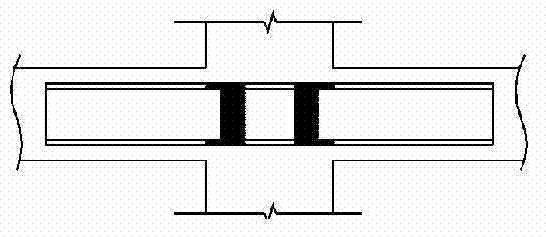

[0024] The spiral shear reinforcement according to the present invention is characterized in that it includes: a spiral steel bar, which is bent into a spiral shape along the length direction, and is formed by a rectangular elliptical spiral whose height is greater than the width and draws an arc toward the width direction; An upper steel bar, which is arranged inscribed along the length direction of the spiral steel bar at the upper high point of the spiral steel bar or on the side surface of the spiral steel bar to join; a lower steel bar, which is arranged inscribed along the length direction of the spiral steel bar. The lower low point of the helix or the lower part of the other side of the helix.

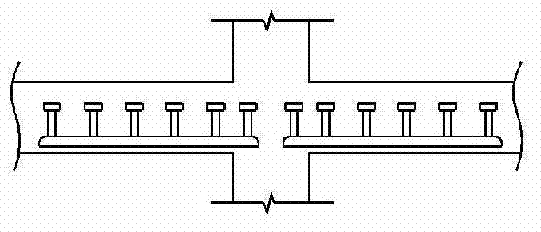

[0025] According to the plate reinforcement structure of the present invention, it is characterized in that it includes: the steel bars in the lower part of the plate, the main reinforcement and the force reinforcement are arranged in a grid pattern; the upper reinforcement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com