Connecting base structure of hydraulic cylinder of material rake of material taking machine

A technology of connecting seat and hydraulic cylinder, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve problems affecting maintenance progress, difficulties, and increasing production costs, and achieve the effects of convenient maintenance, alleviating shear force, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

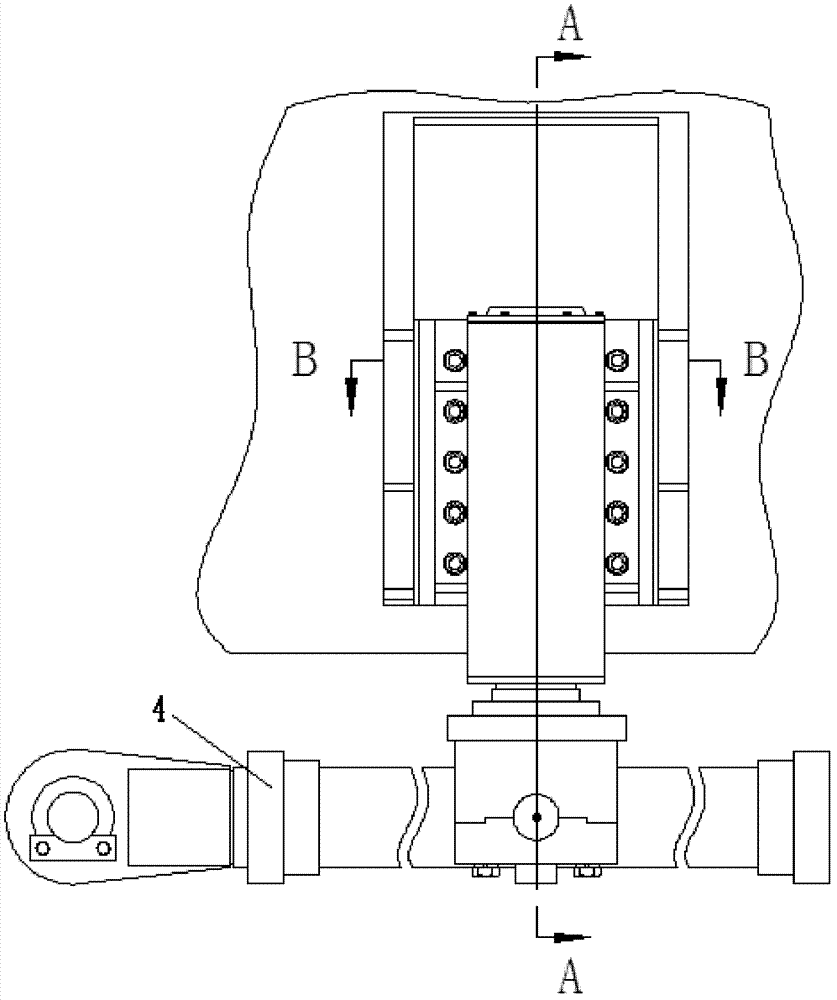

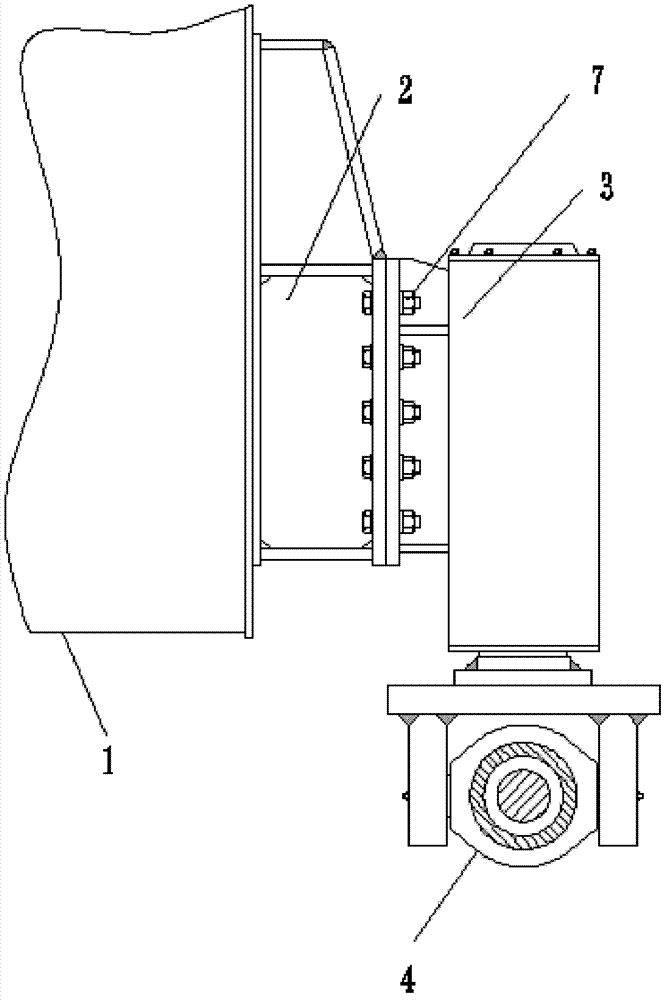

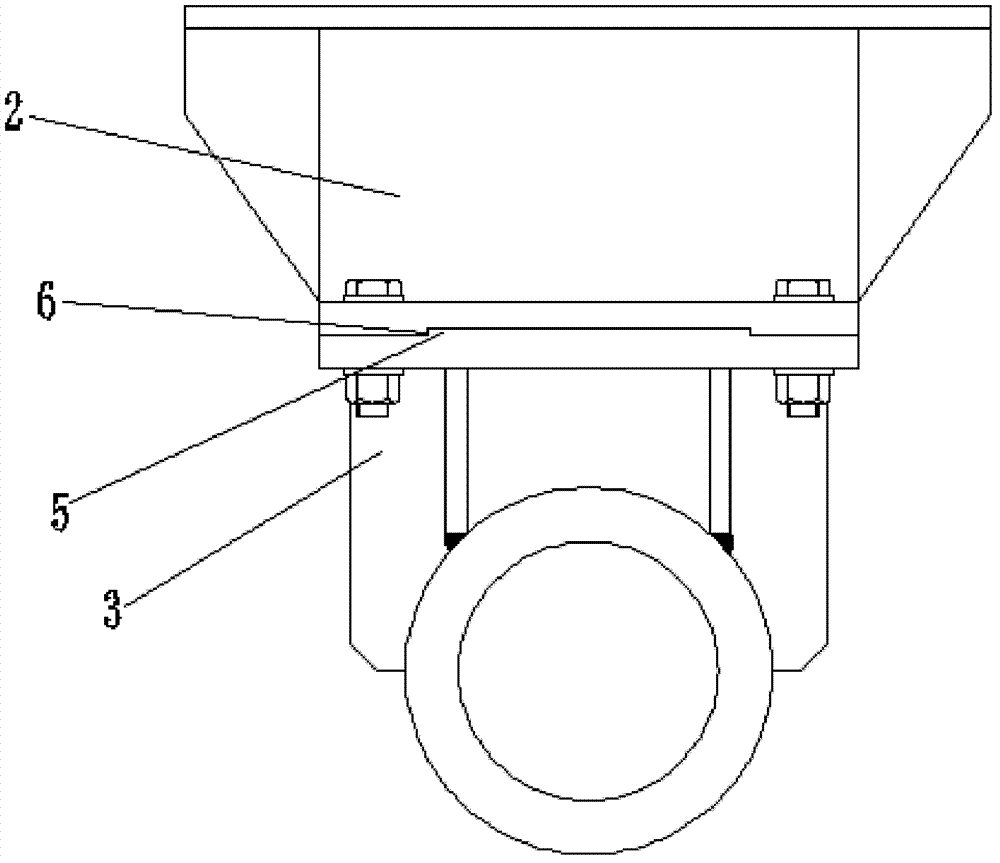

[0018] A coupling seat structure for a material rake hydraulic cylinder of a reclaimer, including a main beam 1, a fixed seat 2, a coupling seat 3 and a hydraulic cylinder 4, the middle part of the hydraulic cylinder is fixed at the lower part of the coupling seat, and the hydraulic cylinder can reciprocate along its axial direction movement; the connecting seat is fixed on the fixed seat; the fixed seat is fixed on the side of the main beam; the contacting surfaces of the connecting seat and the fixed seat are respectively provided with matching convex parts 5 or concave parts 6 . In this way, through the increased cooperating setting of the convex part and the concave part, that is, the setting of the stop, the impact force of the reciprocating movement of the hydraulic cylinder on the fixing bolt can be effectively resisted, and at the same time, the connecting bolt can be replaced with a common precision bolt, which simplifies the structural form.

[0019] Such as image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com