A lightweight wind power generator

A wind power generation device and light-weight technology, which are applied to wind turbines, wind turbine combinations, and wind turbines at right angles to the wind direction, etc., can solve the problems of large destructive power of wearing parts and hinder the development of wind turbines with arc-shaped wind blades. , to achieve the effect of lasting rotational potential energy, avoiding the increase of wearing parts and reducing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

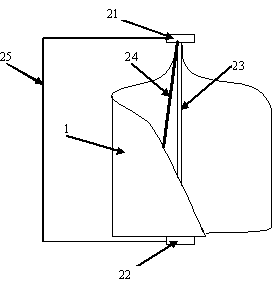

[0029] Such as figure 1 shown.

[0030] The invention relates to a light wind power generating device, which includes a frame structure, a rotating blade device and a generating set.

[0031] The frame structure includes a vertically arranged rotating rod, an upper bearing and a lower bearing are respectively arranged at the top and lower ends of the rotating rod, and the fixing frame arranged in a transverse "U" shape is fixedly connected to the outer end of the upper bearing and the outer end of the lower bearing. The fixed frame is fixedly connected with the bottom end of the power generating device through the bracket, and the lower end of the rotating rod is connected with the input shaft of the engine group.

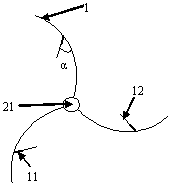

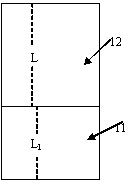

[0032] The rotating blade device includes a wind blade, a speed stop plate arranged on the wind blade, and a reinforcing rib connecting the wind blade and the rotating rod. The wind blade is arranged in an arc shape and has the same length as the rotating rod. Fi...

Embodiment 2

[0042] The invention relates to a light wind power generating device, which includes a frame structure, a rotating blade device and a generating set.

[0043] The frame structure includes a vertically arranged rotating rod, an upper bearing and a lower bearing are respectively arranged at the top and lower ends of the rotating rod, and the fixing frame arranged in a transverse "U" shape is fixedly connected to the outer end of the upper bearing and the outer end of the lower bearing. The fixed frame is fixedly connected with the bottom end of the power generating device through the bracket, and the lower end of the rotating rod is connected with the input shaft of the engine group.

[0044] The rotating blade device includes a wind blade, a speed stop plate arranged on the wind blade, and a reinforcing rib connecting the wind blade and the rotating rod. The wind blade is arranged in an arc shape and has the same length as the rotating rod. Fixedly connected, the wind blades ar...

Embodiment 3

[0054] The invention relates to a light wind power generating device, which includes a frame structure, a rotating blade device and a generating set.

[0055] The frame structure includes a vertically arranged rotating rod, an upper bearing and a lower bearing are respectively arranged at the top and lower ends of the rotating rod, and the fixing frame arranged in a transverse "U" shape is fixedly connected to the outer end of the upper bearing and the outer end of the lower bearing. The fixed frame is fixedly connected with the bottom end of the power generating device through the bracket, and the lower end of the rotating rod is connected with the input shaft of the engine group.

[0056] The rotating blade device includes a wind blade, a speed stop plate arranged on the wind blade, and a reinforcing rib connecting the wind blade and the rotating rod. The wind blade is arranged in an arc shape and has the same length as the rotating rod. Fixedly connected, the wind blades ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com