Rubber belt for bone-meat separator

A technology of separation of flesh and bone and rubber belt, applied in the application, meat processing, slaughtering and other directions, can solve the problems of reducing, increasing and slipping work efficiency, not achieving the desired effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

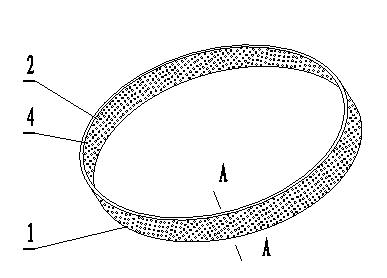

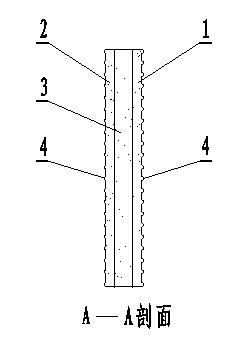

[0011] see figure 1 , figure 2 , rubber belt for bone and meat separator, the rubber belt is a three-layer ring structure, the inner surface layer 2 and the outer surface layer 1 are hard rubber layers, the middle layer 3 is a soft rubber layer, the hardness of the hard rubber layer is 66 degrees, and the hardness of the soft rubber layer is is 46 degrees. The inner surface layer 2, the outer surface layer 1 and the middle layer 3 are all provided with silk mesh. Protrusions 4 are added to the outer surfaces of the inner surface layer 2 and the outer surface layer 1 . Its production method is to use food-grade butyl natural rubber compound in separate furnaces, layered casting and compression molding, vulcanization temperature is 140-160°C, vulcanization pressure is 16±0.5Mpa, and vulcanization time is 500-2000min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com