Design method of creep life of large-sized bright annealing muffle tube and like

A technology of bright annealing and creep life, which is applied in the field of metallurgy, can solve the problems of creep deformation lasting life, reducing the number of repairs and replacements, and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

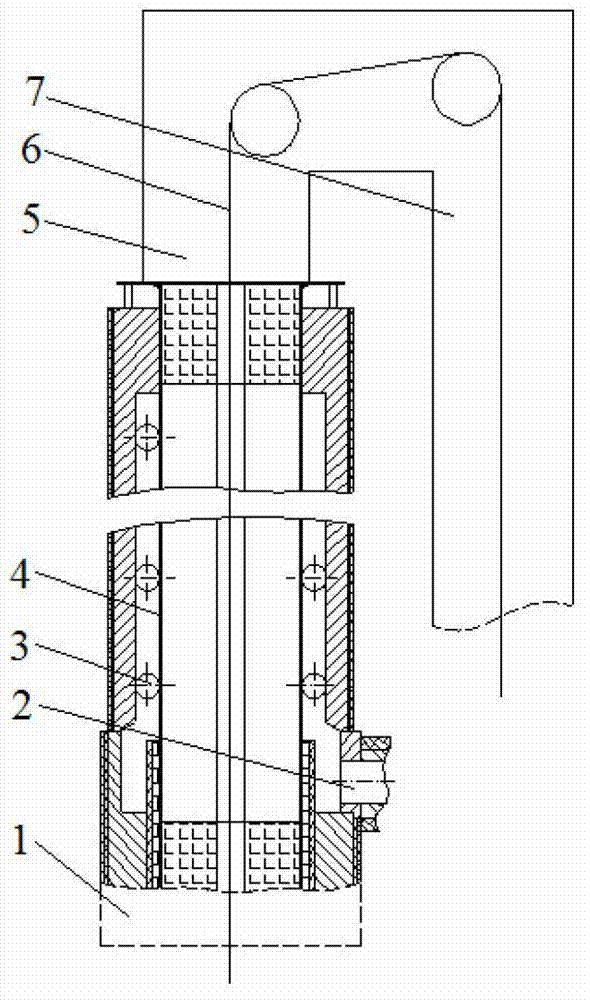

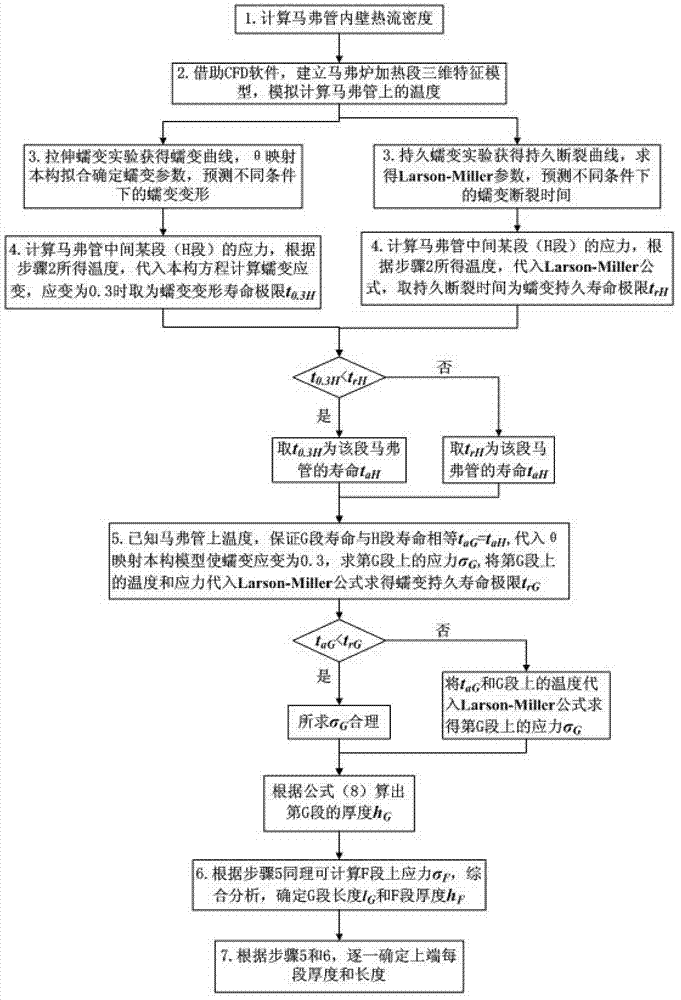

[0068] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

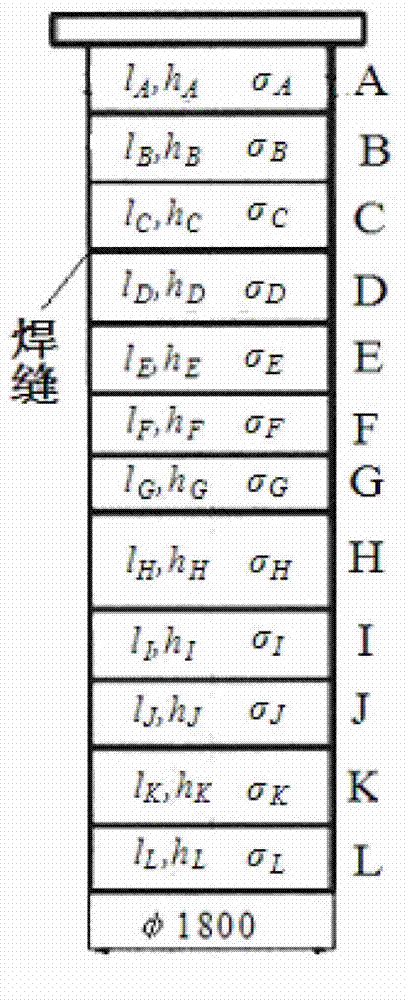

[0069] Step 1: Set the muffle tube to consist of 12 sections from A to L as follows figure 2 As shown, when the muffle tube is used, it is divided into six sections according to the heating section from bottom to top, and the inner wall of the muffle tube in different heating sections is calculated according to the annealed strip material, size specification, and annealing speed into the formula (1). The heat flux is shown in Table 1:

[0070] [Table 1]

[0071] heating section

1

2

3

4

5

6

l / mm

5440

4325

4325

4325

4325

4260

q / w·m -2

-14902

-10308

-9840

-6091

-4217

-1903

[0072] Step 2: With the help of CFD software Fluent, according to the actual muffle furnace structure, heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com