Wire shearing machine for sorting leading wires of stators of generators

A stator lead wire and wire cutting machine technology is applied in the field of automatic wire cutting devices, which can solve the problems of low efficiency, difficulty in ensuring consistent lead wire lengths, and easy occurrence of missing cutting, so as to improve the quality of wire cutting, and improve the quality and stability of wire cutting. , the effect of enhancing functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

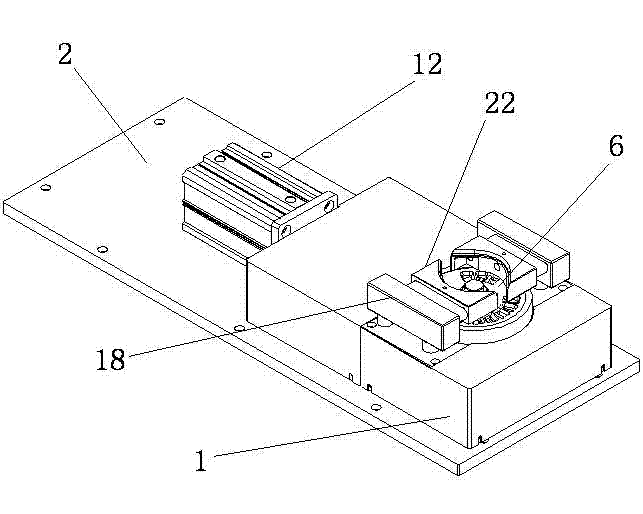

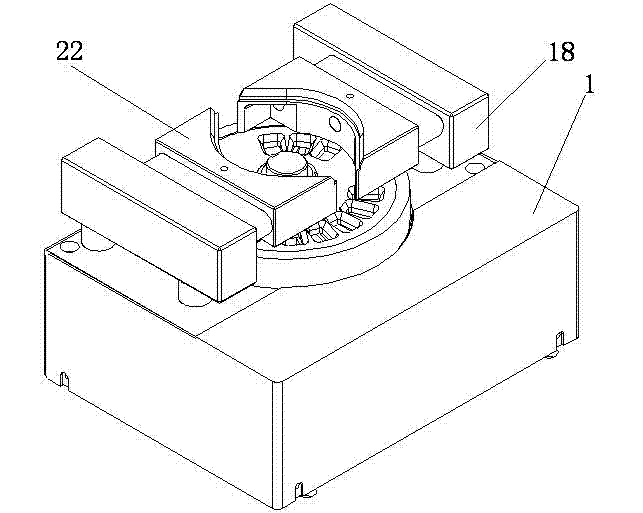

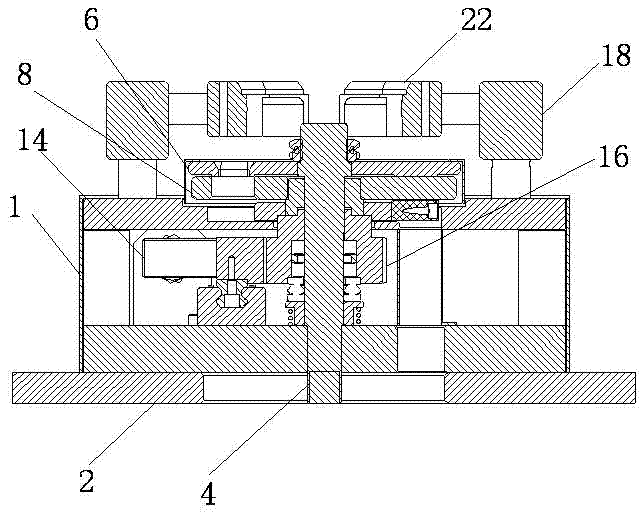

[0017] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0018] Such as Figure 1-3 As shown, a wire trimmer for finishing the stator lead wires of a generator according to the present invention includes a horizontally extending bottom plate 2, a longitudinally extending rotating shaft 4, and circular sheet-shaped upper knives 6 arranged on the rotating shaft 4 and extending parallel to each other laterally. And lower knife 8, and rotating shaft driving device. The lower knife 8 is sleeved on the rotating shaft 4 through the central hole 83 and is fixed on the ring-shaped lower knife fixing seat. The upper knife 6 can rotate synchronously with the rotating shaft 4 and is sleeved and fixed on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com