Electric tool triggered by pressure

A technology for electric tools and work, which is applied in the direction of motor tools, manufacturing tools, and portable motorized devices. It can solve the problems of bit jumping, jumping, and inability to hold postures, etc., and achieves simplified actions, ingenious and novel structures, and reduced jumping. alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

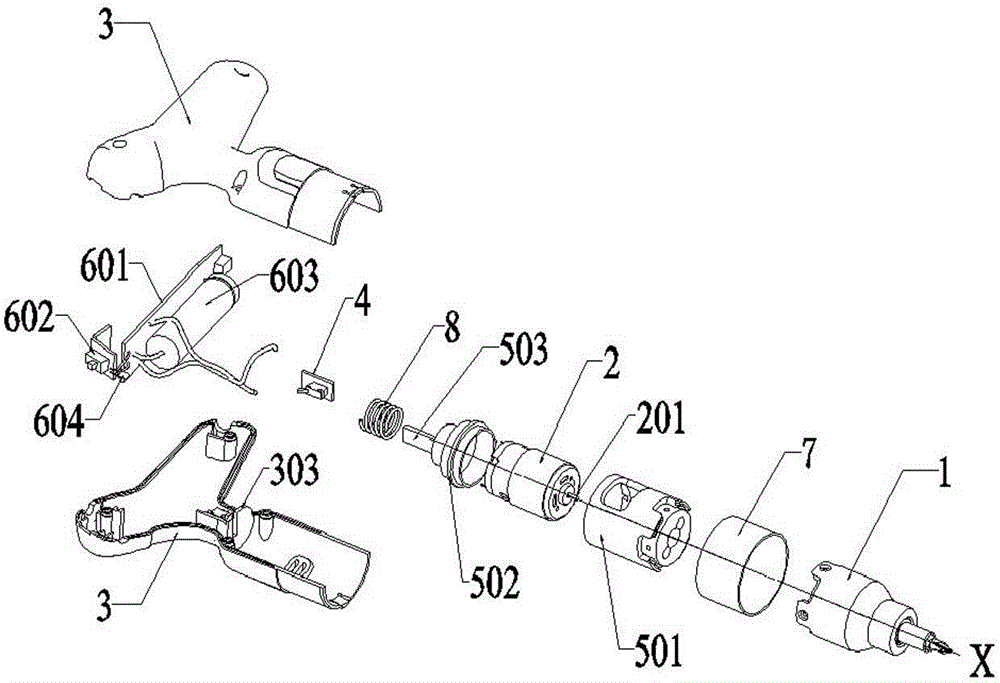

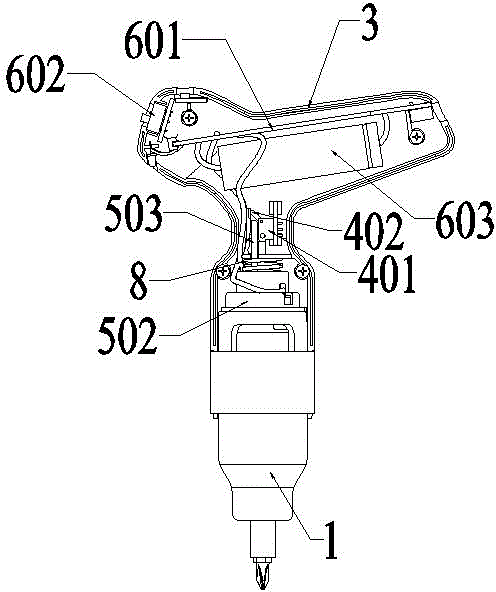

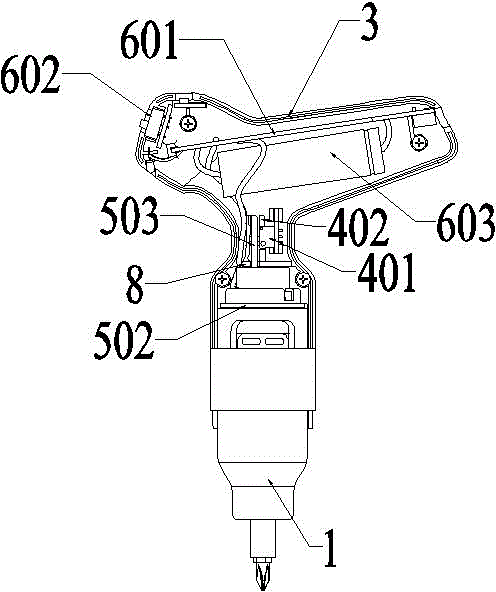

[0034] refer to Figure 1 to Figure 5 As shown, the electric tool of the present invention mainly includes: a working head 1, a motor 2, a handle housing 3, a trigger switch 4, a PCB board assembly, a first elastic member 8, an intermediate assembly, and the like.

[0035] Among them, the working head 1 is an executive mechanism for realizing functions, and is generally integrated with a transmission mechanism and tool accessories. The transmission structure is used to convert the power of the motor into a required form, and the tool accessories are used to realize specific functions. The motor 2 is used to drive the transmission structure of the working head 1. It should be noted that, in the present invention, the power supply for the motor 2 can be a battery or an external line connected to an external power supply. As a preference, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com