A hub clamp

A fixture and hub technology, which is applied in the field of automated tooling and fixtures, can solve the problems of inability to grip special-shaped workpieces, single fixture functions, and easy damage to workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings.

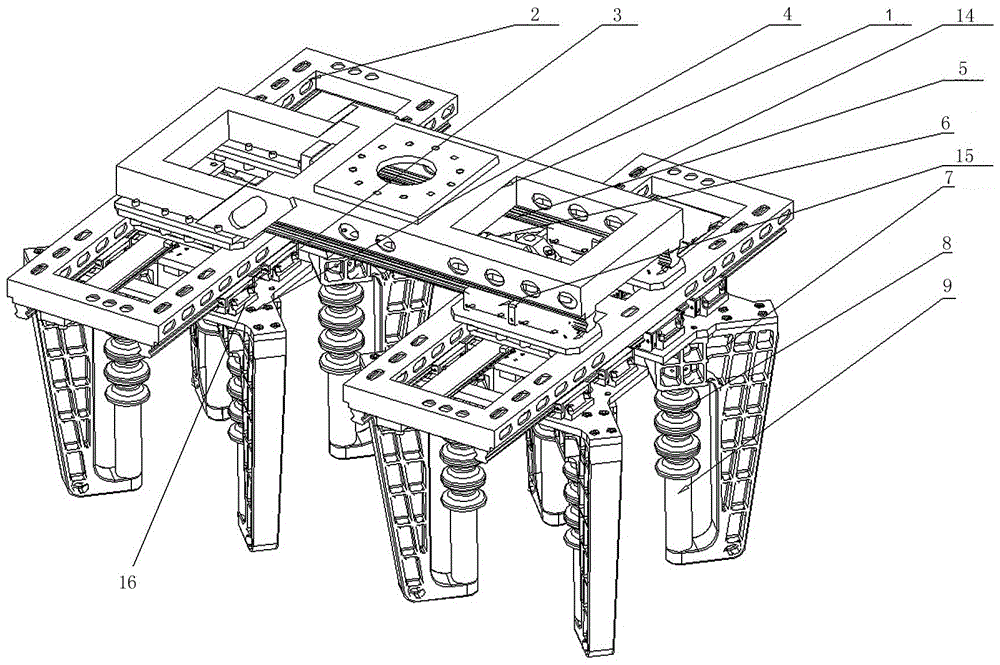

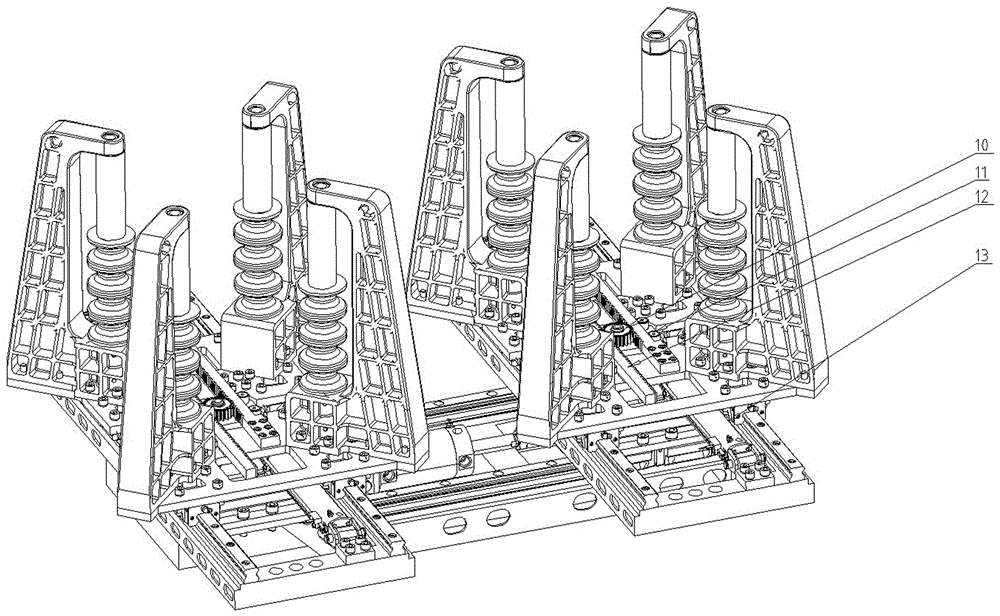

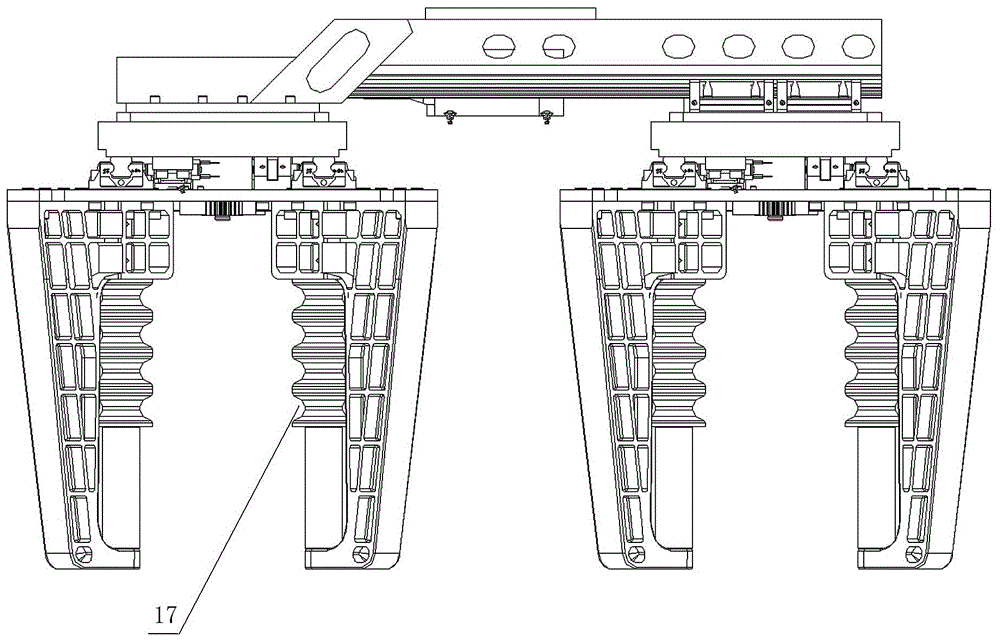

[0012] The present invention is a hub clamp, which includes a main beam 1, which is different from the prior art in that: both sides of the main beam 1 are provided with a sub-beam moving guide rail 5, and the two ends of the main beam 1 are respectively provided with first auxiliary beams. The beam 2 and the second sub-beam 14, the upper surface of the first sub-beam 2 and the second sub-beam 14 are provided with a sub-beam guide rail slider 15, and the first sub-beam 2 and the second sub-beam 14 slide through the sub-beam guide rail The block 15 is movably connected with the sub-beam moving guide rail 5, and the two sides of the lower surface of the first sub-beam 2 and the second sub-beam 14 are respectively provided with a clamping arm moving sub-guide rail 3, and the clamping unit is connected with the clamping unit slide block 16. The clamping arm moves the auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com