Flushing device used for slag tank, and application method thereof

A slag pool and flushing technology, which is applied in the direction of improving process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

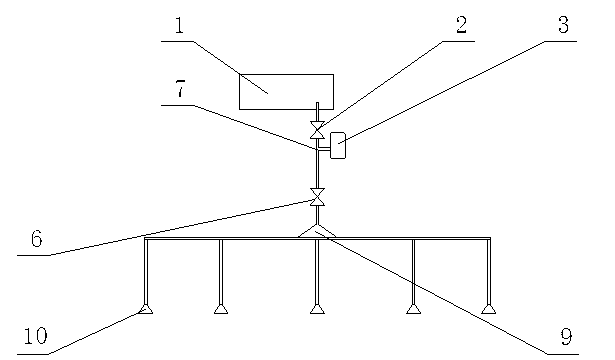

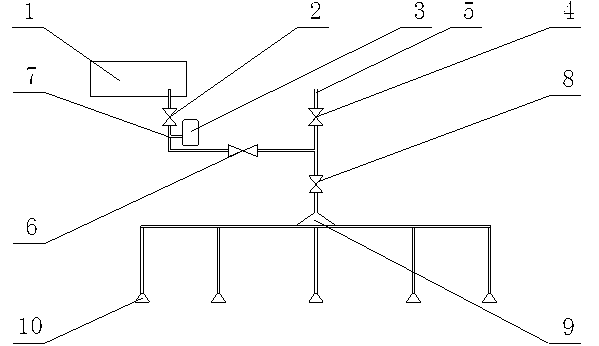

[0025] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0026] The purpose of the present invention is to provide a flushing device for a slag pool and its use method, which uses metallurgical wastewater and compressed air to flush the sediment, so that the slag water in the pool can rotate and mix at high speed, and the manufacturer can recycle it.

[0027] As a specific embodiment of this patent, the present invention provides a structural schematic diagram such as figure 1 The shown flushing device for a slag pond includes a circulating water tank 1, a pressurizing device 3, a connecting pipe 7 and a water nozzle 10, the flushing device for a slag pond is arranged in the slag pond, and the components are connected by The pipeline 7 is connected, and the whole device is composed of pipelines, so that the installation of the whole device is convenient, the investment is small, and the amount of maintenance is low, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com