Automatic measuring device for diameter of bearing ring

An automatic measurement and bearing ring technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of needing replacement, high production requirements, difficult installation and debugging, etc., to achieve the effect of easy installation, no debugging, and less difficulty in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

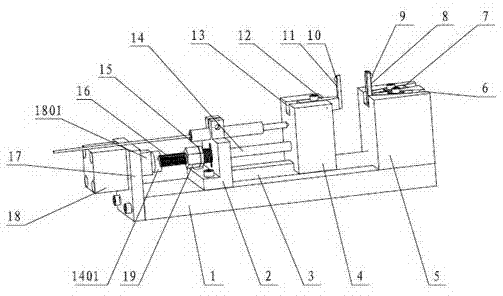

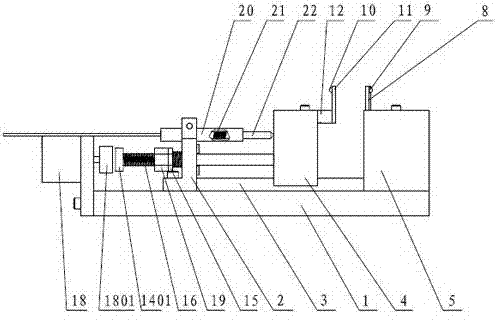

[0026] Example 1: Automatic measuring device for outer finger bearing ring diameter

[0027] Such as figure 1 , 2 As described in and 3, the bearing ring diameter automatic measuring device includes a base plate 1, a fixed measuring seat 5, a dynamic measuring slide 4, a slide rail 3, a measuring mechanism and a measuring pen.

[0028] One end of the base plate 1 is fixedly provided with a fixed measuring seat 5, and two limiting grooves II6 are arranged on the fixed measuring seat 5, and the two limiting grooves II6 form a V-shaped structure, and the bisector of the angle formed by the two limiting grooves II6 and the sliding The rails 3 are in the same straight line direction, and the head of the V-shaped structure points to the dynamic measuring slide 4. The bottom of each limiting groove II6 is provided with a screw hole for fixing a fixed measuring block, and a fixed measuring block is arranged in the limiting groove II6. The measuring block includes a measuring rod 8 ...

Embodiment 2

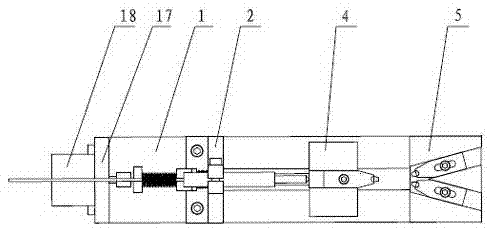

[0038] Example 2: Automatic measuring device for inner finger of bearing ring diameter

[0039] Such as Figure 4 , 5 As described in and 6, the bearing ring diameter automatic measuring device includes a base plate 1, a fixed measuring seat 5, a dynamic measuring slide 4, a slide rail 3, a measuring mechanism and a measuring pen.

[0040] One end of the base plate 1 is fixedly provided with a fixed measuring seat 5, and two limiting grooves II6 are arranged on the fixed measuring seat 5, and the two limiting grooves II6 form a V-shaped structure, and the bisector of the angle formed by the two limiting grooves II6 and the sliding The rails 3 are in the same straight line direction, and the head of the V-shaped structure points to the dynamic measuring slide 4. The bottom of each limiting groove II6 is provided with a screw hole for fixing a fixed measuring block, and a fixed measuring block is arranged in the limiting groove II6. The measuring block includes a measuring ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com