Parallel seam welding process and apparatus of special-shaped structure packaging housing

A technology of encapsulating shells and parallel seam welding, which is applied to metal shells, welding equipment, manufacturing tools, etc., can solve problems such as ugly appearance, difficult to achieve product airtightness, rough weld seam, etc., and achieve beautiful appearance, good airtightness, and welding Thin and smooth seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

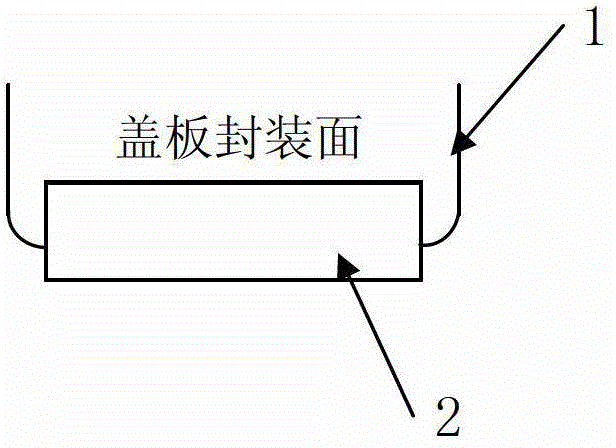

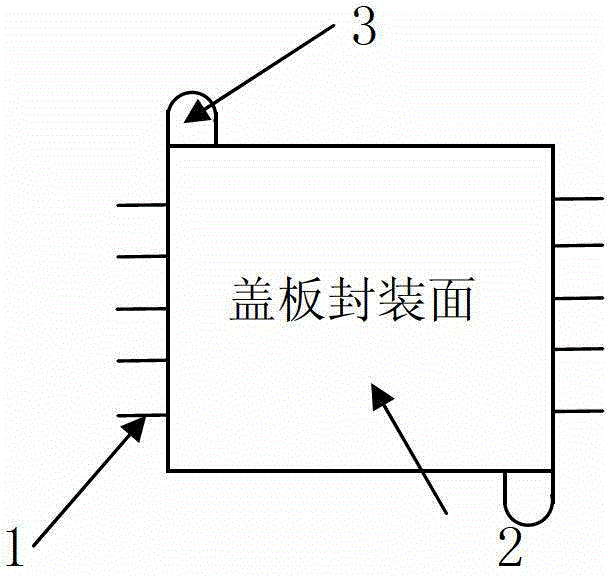

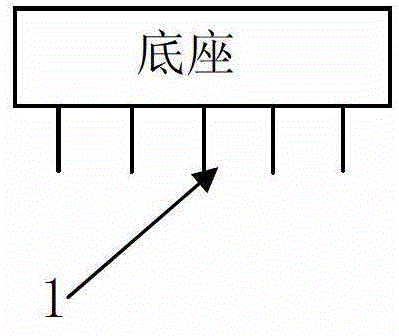

[0024] Such as Figure 3-2 As shown, first fine-tune the X and Y direction knobs of the sealing and welding mold 6 to ensure that the front, rear, left, and right are completely symmetrical, that is, the center of the product, the center of the mold, and the center of the line connecting the two welding wheels are absolutely coincident, and the track is preset at 96-99 (0.096 ~0.099 inches); Then open a groove 7 with a width of 2 mm and a depth of 2 mm at the position where the axle 4 of the sealing welding electrode wheel bears against the lead wire 1, so that the end of the lead wire is in the groove shape; finally, the fine-tuning track is set to 100-103 (ie 0.100 to 0.103 inches), the outer edge of the sealing surface 5 is used for sealing and welding, which can avoid the "ears" 3, and weld the cover plate 2, the base and the "ears" 3 together.

[0025] When packaging, the product must be placed in the center of the mold according to the process requirements. The cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com