Furnace top sealing device

A technology for sealing devices and furnace tops, which is applied in furnaces, blast furnaces, and details of blast furnaces. It can solve the problems of high top pressure, deformation of sealing covers, and poor sealing of furnace tops in blast furnaces, so as to improve operating efficiency and reduce production costs. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

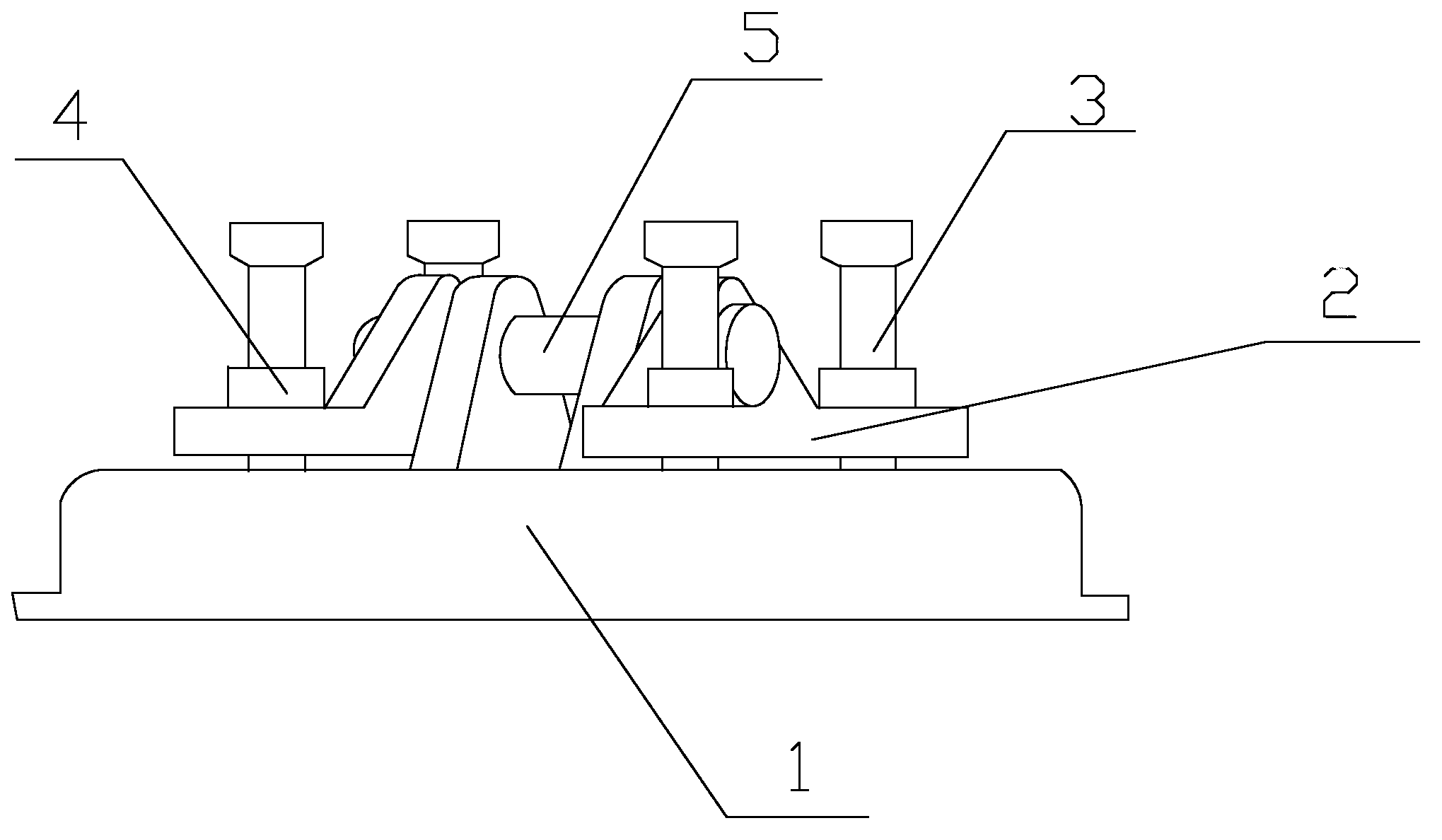

[0010] A furnace roof sealing device provided in this embodiment is suitable for blast furnace roof large discharge. Four bolts 3 and four nuts 4 matched therewith are arranged, and the height of these bolts and nuts can be adjusted up and down. At the same time, the pressing plate is connected with the sealing cover through a pin shaft 5 .

[0011] In the present invention, the sealing cover is squeezed by adjusting the height of the bolt and the nut, so that the sealing cover is slightly deformed, and the sealing performance of the sealing cover is significantly improved. The furnace top pressure can be increased by installing the furnace top sealing device, and the comprehensive benefit of blast furnace production can be improved. The design has remarkable effect, strong practicability, improved operation efficiency, simple structure, easy operation and low production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com