Alkali-refining process of vegetable oil with high content of unsaturated acid

A technology of acid content and vegetable oil, which is applied in the field of vegetable oil refining, can solve the problems of unsatisfactory oil materials, etc., and achieve the effects of improving product quality and economic benefits, wide application range, and high comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

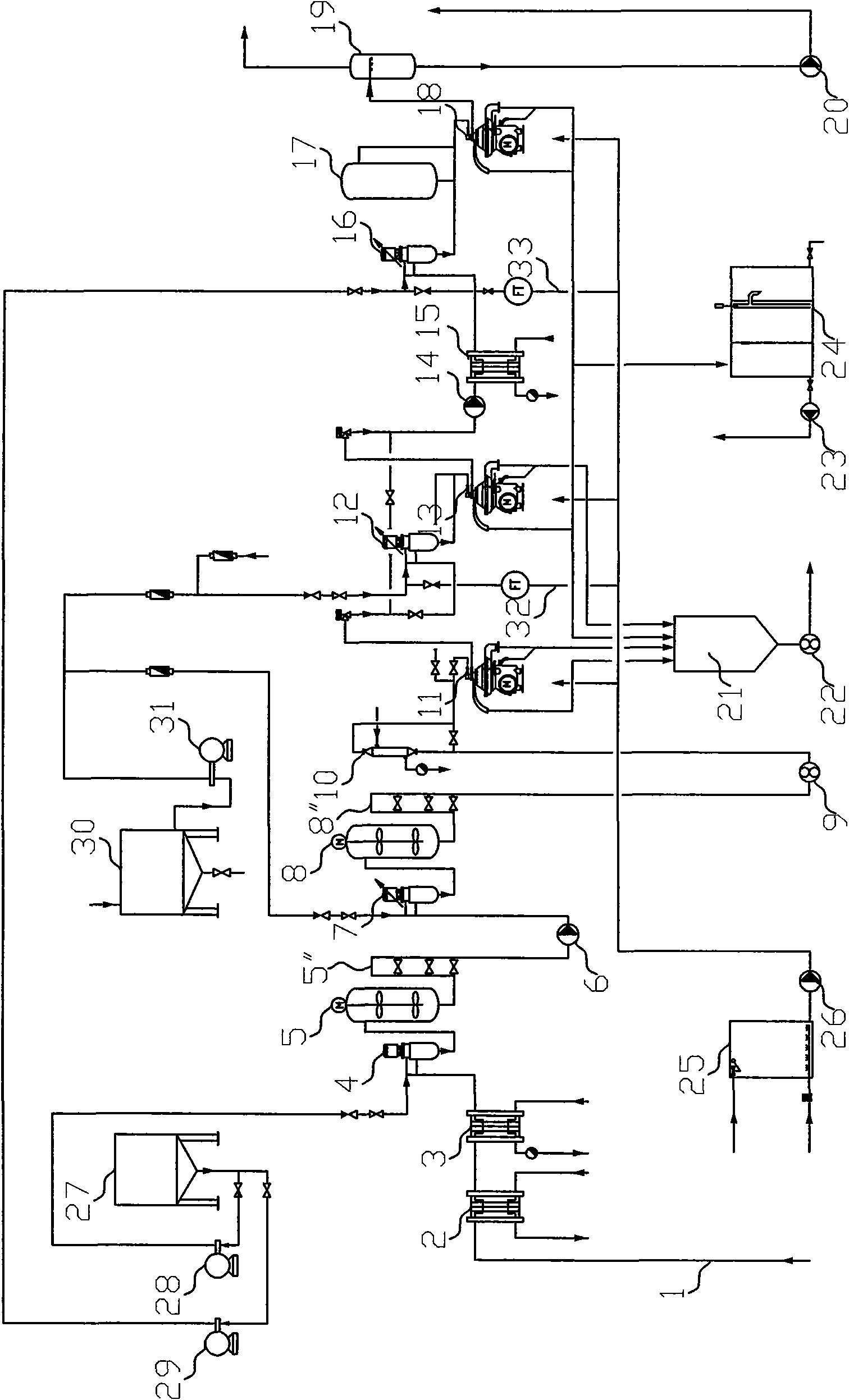

[0012] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as shown in Figure 1, in the present invention, the outlet of the acidification tempering tank 5 in the long-term mixing and short-mixing process is equipped with an overflow outlet pipeline 5 ", through the installation on the pipeline Several sets of valves with different heights are used to adjust the time of acidification and tempering of the raw material oil. An overflow outlet pipeline 8" is installed at the outlet of the alkali delay tank 8, and several sets of valves with different heights installed on the pipeline are used to adjust the alkali neutralization The reaction time, through the above process configuration, realizes the mutual switching of long-mixing / short-mixing in the alkali refining process.

[0013] As shown in Figure 1, any one of the soap-removing centrifuge 11 and the soap-removing centrifuge 13 can form an alkali refining process of soap removal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com