Composite buffer

A technology of composite buffering and buffering pad, which is applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problem of not being able to completely suppress bouncing, and achieve the effect of reducing impact and restraining bouncing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

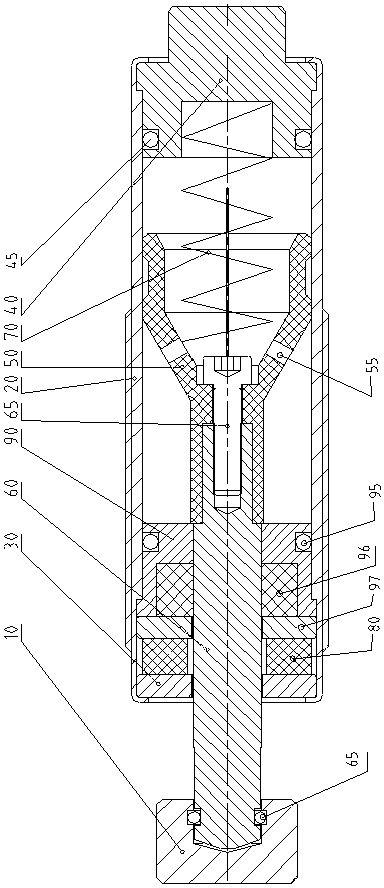

[0017] see figure 1 , the embodiment of the present invention includes:

[0018] A composite buffer, comprising: a limit device 10, a cylinder 20, a cover 30 installed in the inner cavity of the cylinder 20, a lower cover 40, a piston 50, a piston rod 60, a spring 70, and a buffer pad 80 and cage 90.

[0019] The cover 30 and the lower cover 40 are respectively fixed on two ends of the cylinder body 20 . In this embodiment, the outer surface of the lower cover 40 is stepped, and is fixed by cooperating with the surface of the inner cavity of the cylinder body 20. At the same time, in order to ensure the sealing performance, the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com