Deironing filter of concrete blender

A concrete mixer and filter technology, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as misjudgment of equipment quality, misjudgment of the quality of electrical equipment by testing equipment, and inability to know whether concrete contains metal substances. , to achieve the effect of ensuring quality and ensuring experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The present invention will be described below in conjunction with specific embodiments.

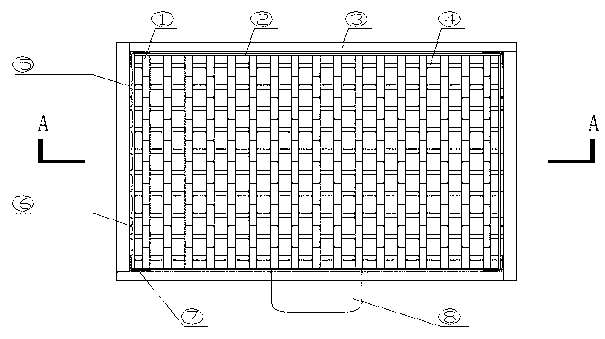

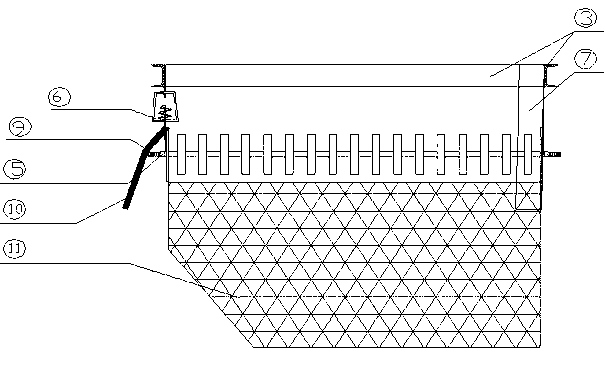

[0013] in figure 1 Among them, 8# channel steel is made into a rectangular support frame with a cross-sectional size of 1230*1030, that is, the cross-sectional size of the discharge port is 400+300*2 (the actual size can be determined according to the power of the discharge machine) + two flat steel size 12mm+ The size of the two shock absorber rods is 8mm + installation error 10mm. Then use angle steel as a column to weld the support frame to the receiving opening. The support frame is 355mm higher than the upper opening of the receiving opening, that is, the base of the flat vibrator is 200mm + the size of the shock absorber is 150mm + the gap is 5mm.

[0014] Use 6# flat steel to make a rectangular frame with a side length of 1200*1000*200 (height), and then use Φ12 round steel with both ends of the wire in the middle of the frame to arrange the neodymium iron boron magnets at a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com