Steel coil unfolding assistant device

An auxiliary device and steel coil technology, which is applied in the field of steel coil auxiliary unwinding devices, can solve the problems of uncoilers that cannot feed materials, affect normal production, and low efficiency, and achieve the effects of convenient unwinding, simple structure, and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

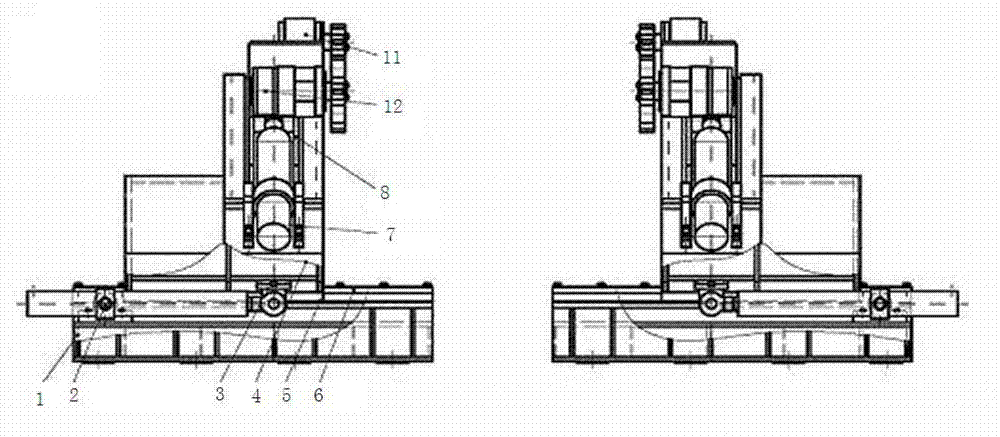

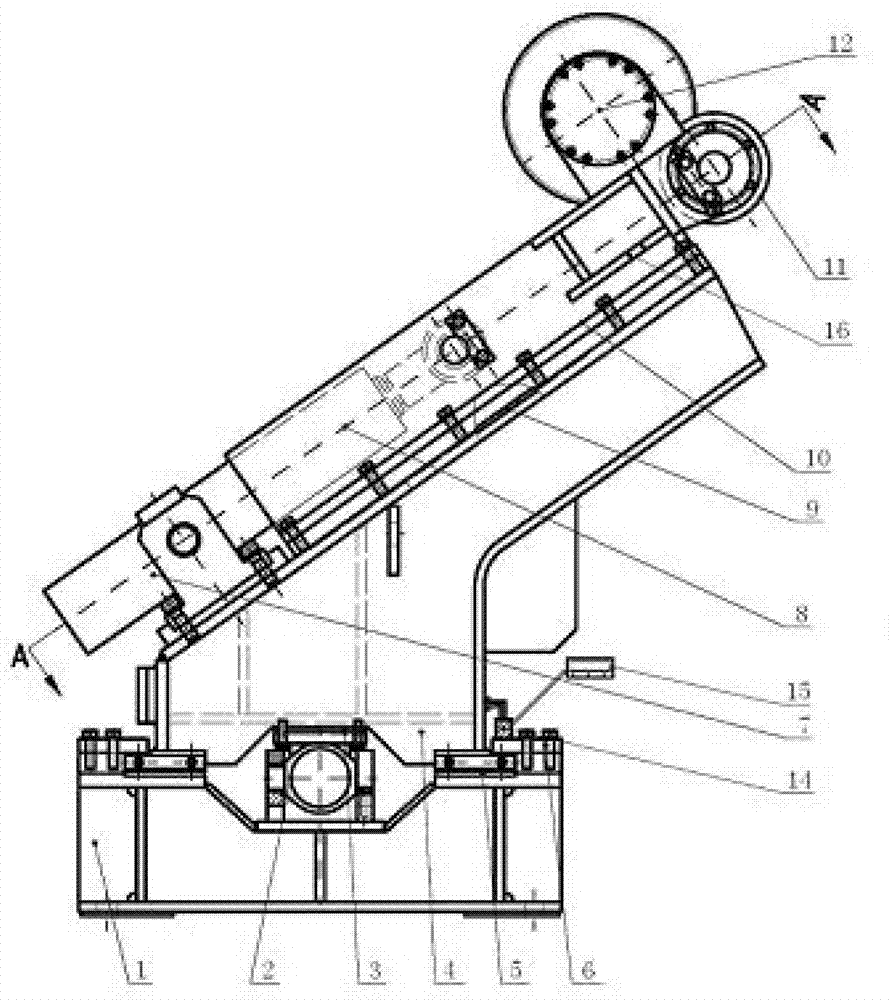

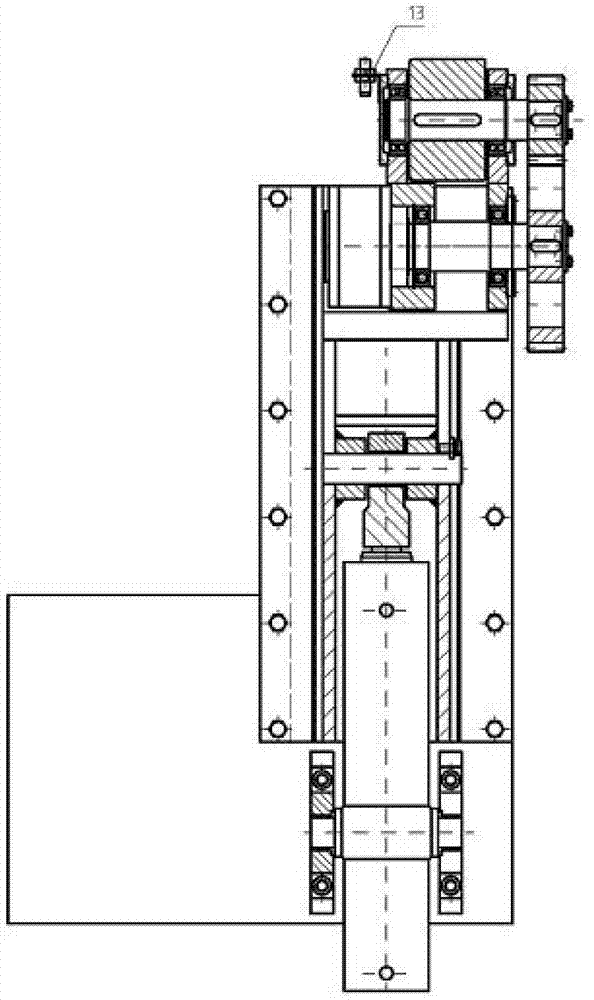

[0017] The labels of the components in the drawings are as follows: base 1, traverse cylinder 2, ear seat 3, sliding frame 4, guide rail plate 5, pressure plate 6, support cylinder 7, support frame 8, support guide rail plate 9, support platen 10. Supporting roller 11, hydraulic motor 12, proximity switch 13, displacement sensor 14, digital display 15, supporting roller support 16.

[0018] see Figure 1-3 Shown: the present invention consists of two mechanisms with symmetrical structures, which are respectively installed on the left and right sides of the steel coil front of the uncoiler, and use the supporting roller 11 to exert force on the surface of the steel coil to control the loosening of the steel coil; wherein the structure of each mechanism is The base 1 is fixed on the ground, and the traversing oil cylinder 2 and the sliding frame 4 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com