A kind of hot-melt welding device and hot-melt welding method for plastic thin-walled pipe cone mouth

A plastic thin-walled, hot-melt welding technology, which is applied to the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve problems such as insufficient curling, uneven heights on both sides of the weld bead, and interface misalignment, so as to prevent butt joint misalignment, The effect of reducing quality accidents and improving the strength of hot-melt butt joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

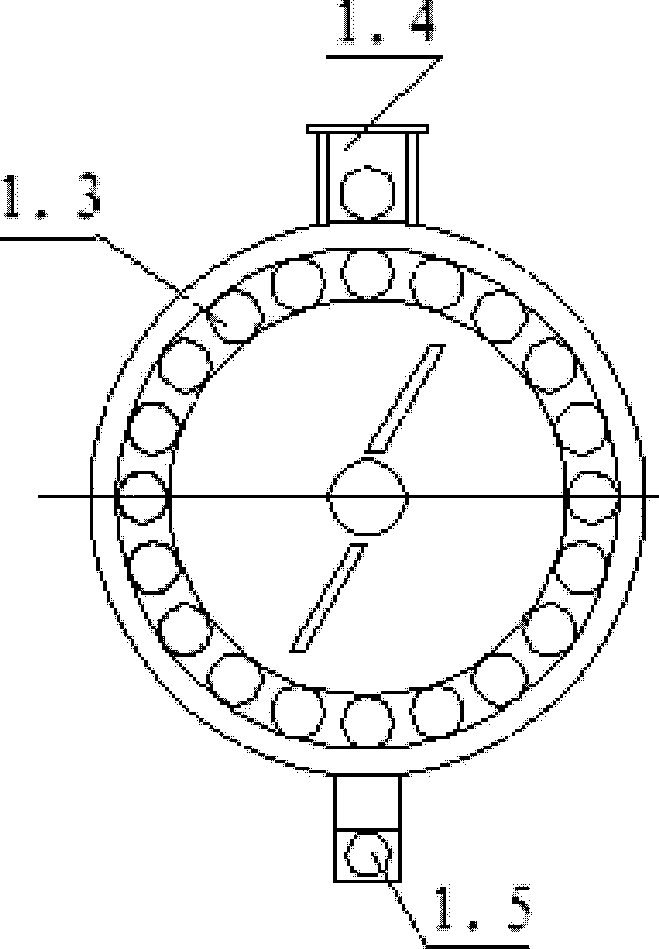

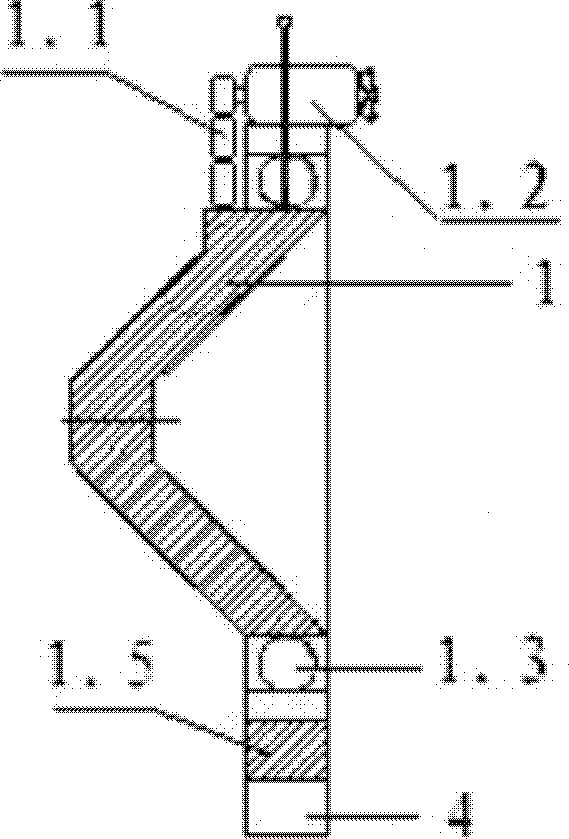

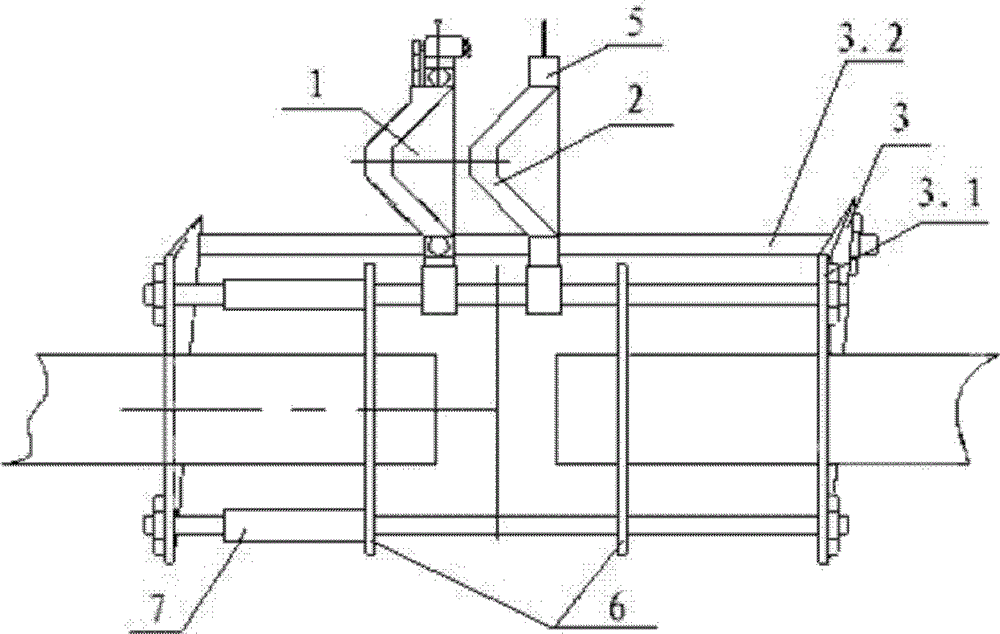

[0049] The tapered milling cutter of the present invention changes the two faces of the milling cutter into two inner and outer faces with an included angle of 45 degrees on the basis of the flat milling cutter. The bearing is fixed, and the power of the motor is used to drive the gear to rotate the milling cutter to fix the two joints of the pipe or pipe fittings on the same axis, and cut out a female and a male socket with equal angles (Figure 1).

[0050] Among them, the conical milling cutter can be designed as an independent part, which can be manually picked up and placed in the frame for fixing pipes or pipe fittings. The advantage is that it is easy to carry in the field and saves costs. The disadvantage is that the operation is greatly affected by human beings.

[0051] In the specific implementation, it can be designed as a frame-connected body, which is convenient to operate and reduces labor intensity. It can realize automatic operation when equipped with a lifting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com