Preloaded spring leaf and its combined structure and fan

A pre-compressed spring, combined structure technology, applied in the direction of springs, spring assemblies composed of several springs, springs/shock absorbers, etc., can solve the problem that the shaft cannot be reliably buckled, the vibration and noise of the bearing, and the uneven spring force. role, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

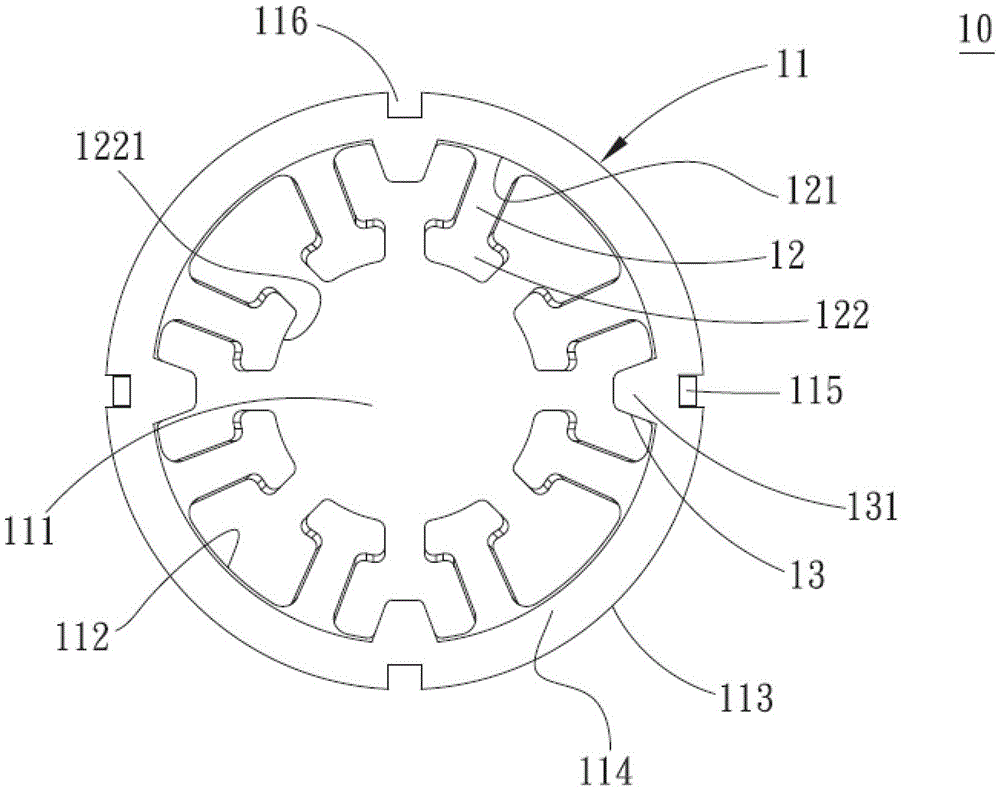

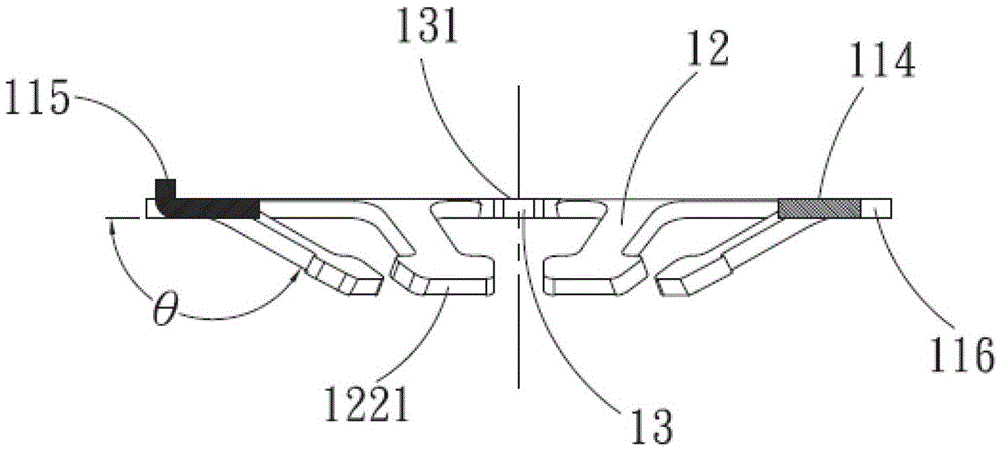

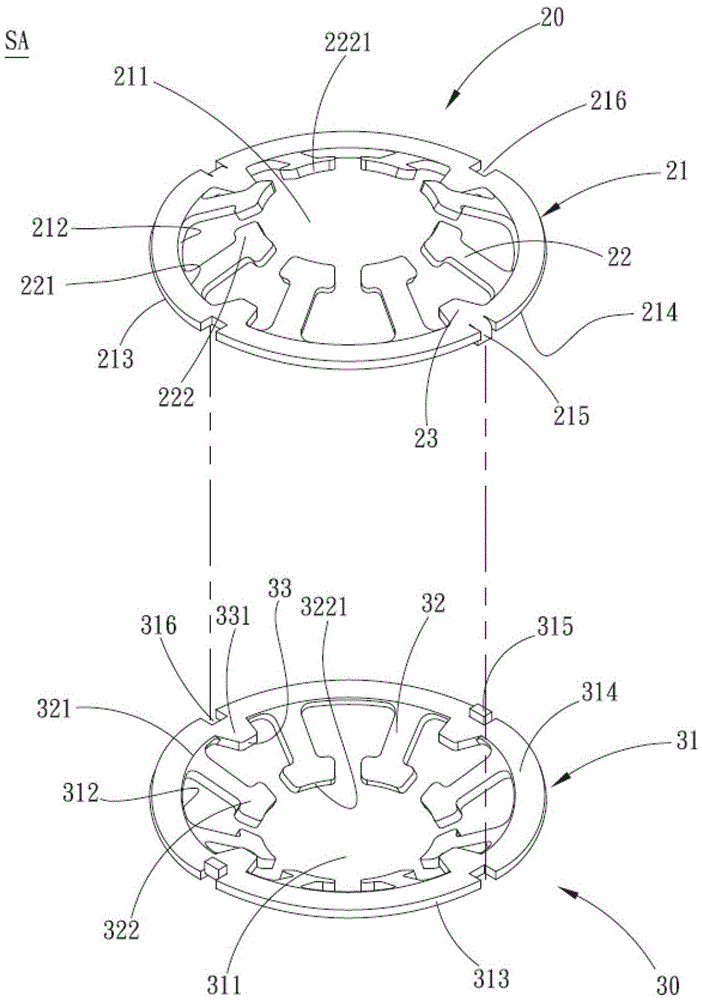

[0083] see Figure 1A and Figure 1B , is a schematic diagram of a pre-compression spring 10 , which includes a body 11 , a plurality of extension elements 12 and at least one protrusion 13 as shown in the figure.

[0084] The main body 11 has an inner surface 112 defining a through hole 111 passing through the main body 11, so that the main body 11 is formed into an annular body, and an outer surface 113 is defined on the outer peripheral side of the main body 11, and a first contact surface 114 is defined on the outer peripheral side of the main body 11. Between the outer surface 113 and the inner surface 112 .

[0085] At least one engaging portion 115 and at least one engaging groove 116 are distributed on the outer surface 113 or adjacent to the outer surface 113, wherein the engaging portion 115 protrudes from the first contact surface 114, and the engaging groove 116 is provided on the outer surface 113 without The position of the engaging portion 115 is recessed towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com