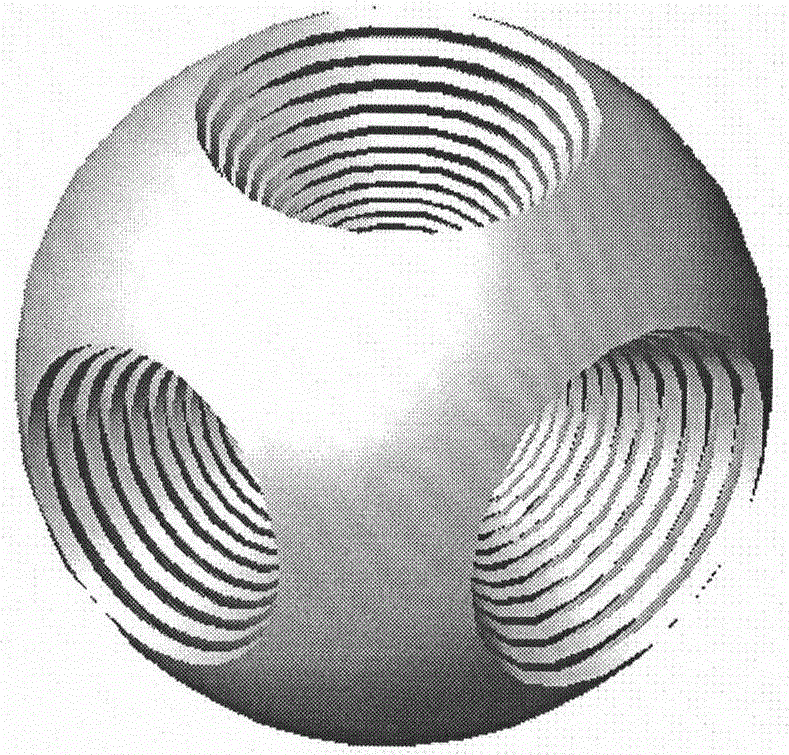

Concentric spheres and methods of making the same

A manufacturing method and technology of concentric spheres, which are applied in decorative arts, special decorative structures, etc., can solve problems such as brittleness, difficulty in processing, inability to process concentric spheres, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

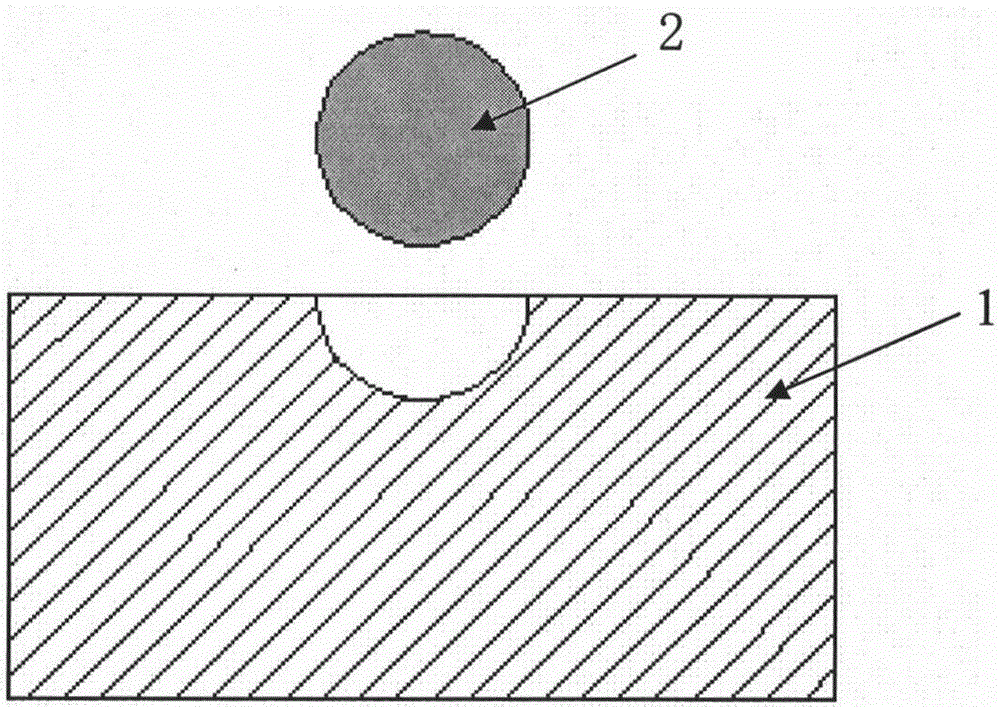

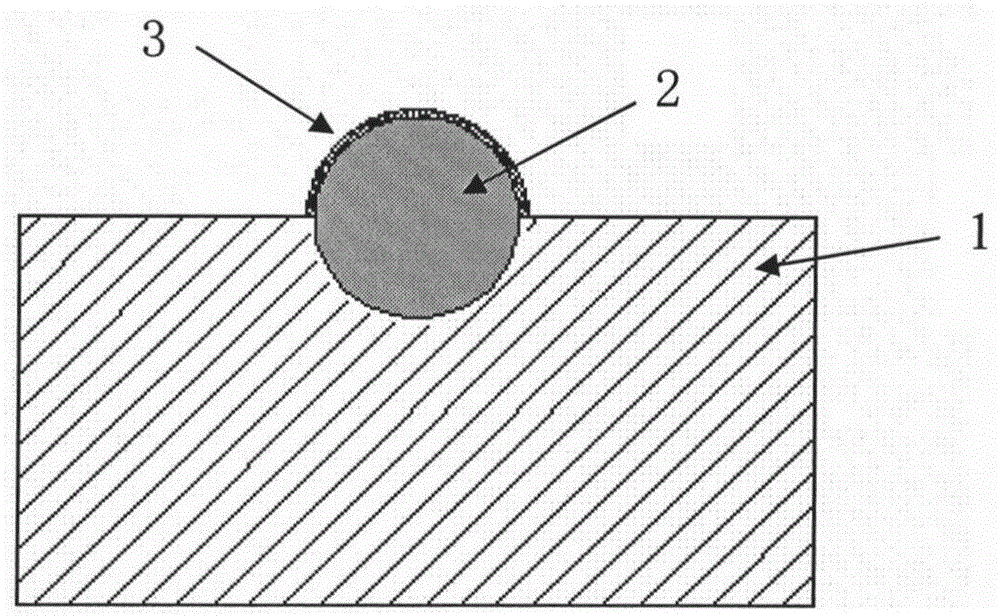

[0032] As shown in the figure, the present invention discloses a processing method for making ceramic concentric spheres, comprising the following steps:

[0033] Step 1: Design and make mold 1 for manufacturing concentric spheres. The number of molds required depends on the number of layers of concentric spheres. Each layer of ceramic layer and each layer of isolation layer requires a pair of molds. Each pair of molds is similar in shape, only different in size. The main feature of the mold 1 is that each mold has a hemispherical hollow cavity, so that the ceramic ball green body and the isolation layer spherical body of each layer can just be put into the hemispherical hollow cavity of the mold 1;

[0034] Step 2, prepare the ceramic body material, isolation material and anti-adhesive material for making the concentric sphere. Ceramic concentric spheres must be sintered at high temperature, so the shrinkage rate of the ceramic body material and the isolation material must b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com