A kind of production method of high-speed steel composite roll

A composite roll and production method technology, which is applied in the field of roll preparation, can solve the problems of high manufacturing cost and inability to process rolls, and achieve the effects of reducing production costs, prolonging the service life, and increasing the number of rolls used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

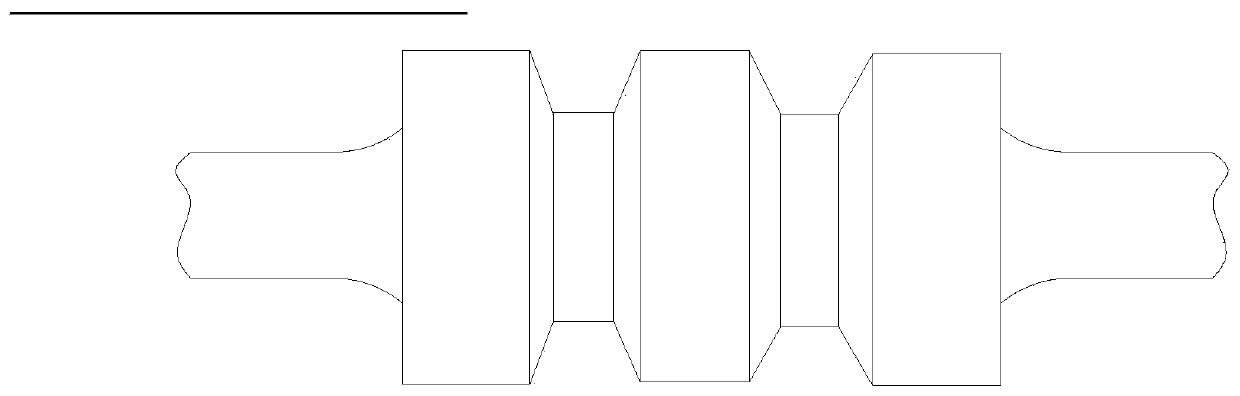

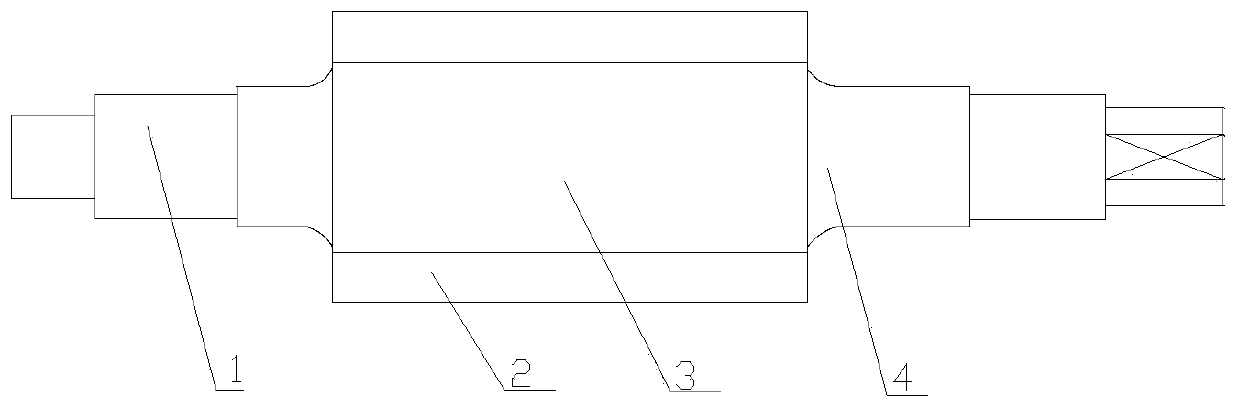

Image

Examples

Embodiment 1

[0029] The formula of the high-speed steel material for the roll body is: C 1.92%, Si 0.85%, Mn 0.63%, Cr 6.12%, Mo5.19%, W 2.82%, V 3.89%, P 0.029%, S 0.026%, and the balance is Fe ;

[0030] The formula of the roll neck ductile iron material at both ends of the roll is: C 3.28%, Si 2.56%, Mn 0.70%, Ni0.69%, Cr 0.25%, Mo 0.22%, P 0.032%, S 0.032%, and the balance is Fe;

[0031] (1) Centrifugal casting of high-speed steel molten steel on the outer layer of the roll body:

[0032] First, the high-speed steel material of the roll body and the ductile iron material of the roll neck are smelted separately according to the specific composition requirements. When the chemical composition and temperature of the two materials meet the set requirements, the high-speed steel molten steel for the outer layer of the roll is first discharged, and the high-speed steel molten steel for the outer layer is firstly smelted. After the slag is removed from the steel, it is poured into the centr...

Embodiment 2

[0041]The formula of the high-speed steel material for the roll body is: C 1.92%, Si 0.85%, Mn 0.63%, Cr 6.12%, Mo5.19%, W 2.82%, V 3.89%, P 0.029%, S 0.026%, and the balance is Fe ;

[0042] The formula of the roll neck ductile iron material at both ends of the roll is: C 3.28%, Si 2.56%, Mn 0.70%, Ni0.69%, Cr 0.25%, Mo 0.22%, P 0.032%, S 0.032%, and the balance is Fe;

[0043] (1) Centrifugal casting of high-speed steel molten steel on the outer layer of the roll body:

[0044] First, the high-speed steel material of the roll body and the ductile iron material of the roll neck are smelted separately according to the specific composition requirements. When the chemical composition and temperature of the two materials meet the set requirements, the high-speed steel molten steel for the outer layer of the roll is first discharged, and the high-speed steel molten steel for the outer layer is firstly smelted. After the slag is removed from the steel, it is poured into the centri...

Embodiment 3

[0053] The formula of the high-speed steel material for the roll body is: C 1.78%, Si 0.72%, Mn 0.61%, Cr 6.02%, Mo5.15%, W 2.66%, V 3.83%, P 0.022%, S 0.025%, and the balance is Fe ;

[0054] The formula of the roll neck ductile iron material at both ends of the roll is: C 3.25%, Si 2.76%, Mn 0.80%, Ni0.63%, Cr 0.29%, Mo 0.21%, P 0.030%, S 0.029%, and the balance is Fe;

[0055] (1) Centrifugal casting of high-speed steel molten steel on the outer layer of the roll body:

[0056] First, the high-speed steel material of the roll body and the ductile iron material of the roll neck are smelted separately according to the specific composition requirements. When the chemical composition and temperature of the two materials meet the set requirements, the high-speed steel molten steel for the outer layer of the roll is first discharged, and the high-speed steel molten steel for the outer layer is firstly smelted. After the slag is removed from the steel, it is poured into the centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com