Method for acquiring container ship resistance

A technology for container ships and ships, applied in ship parts, ship construction, transportation and packaging, etc., can solve the problems of a large number of testing equipment, manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

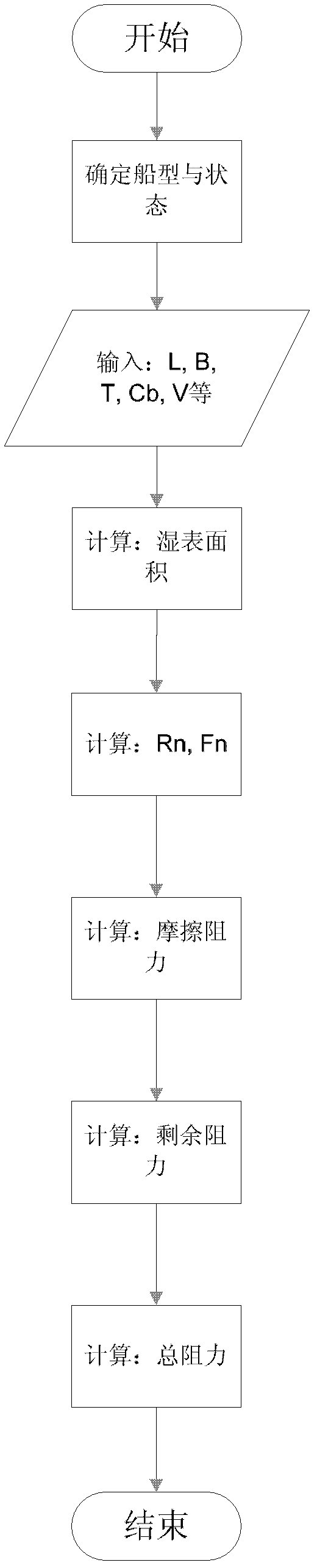

[0060] Such as figure 1 As shown in the flow chart, the process of obtaining ship resistance in the present invention first needs to obtain the main dimensions and related parameters of the ship through design or measurement, specifically including the following process.

[0061] Step 1. Preliminarily determine the main dimensions and other relevant parameters of the designed ship, as follows;

[0062] Lbp: length between vertical lines (m)

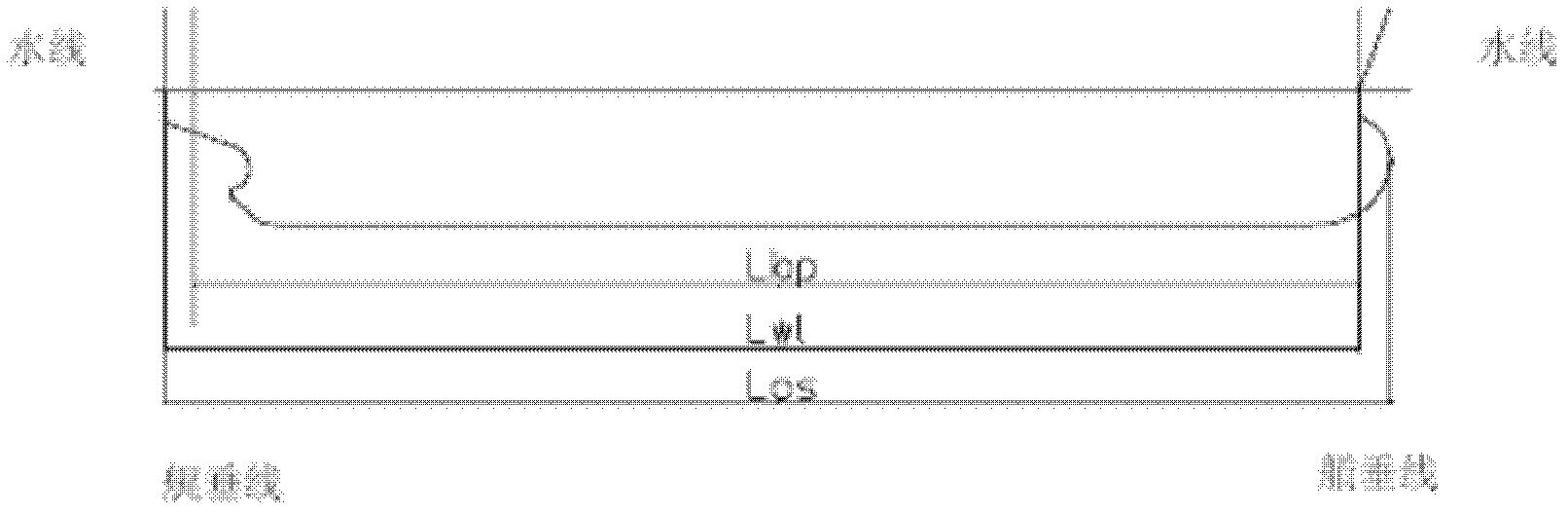

[0063] Los: the total length of the waterline (m) (the total length of the waterline is the distance between the rear end of the ship's calculated waterline and the front end below the waterline, such as figure 2 shown)

[0064] Lwl: waterline length (m)

[0065] B: Type width (m)

[0066] T: Draft (m)

[0067] Ta: stern draft (m)

[0068] Tf: bow draft (m)

[0069] Dp: propeller diameter (m)

[0070] The following parameters are obtained by design or calculation:

[0071] Cb: square coefficient

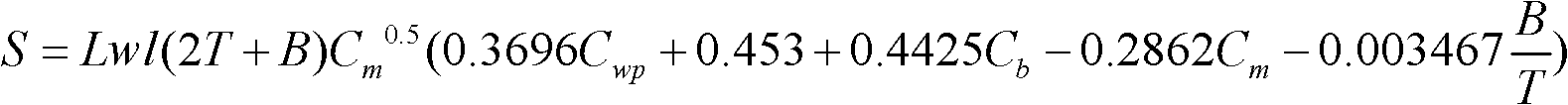

[0072] Cwp: waterplane coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com