Cable provided with reinforcing board and reinforcing board

A technology for strengthening boards and cables, applied in the direction of flat/ribbon cables, insulated cables, cables, etc., to achieve the effect of ensuring firm connection and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

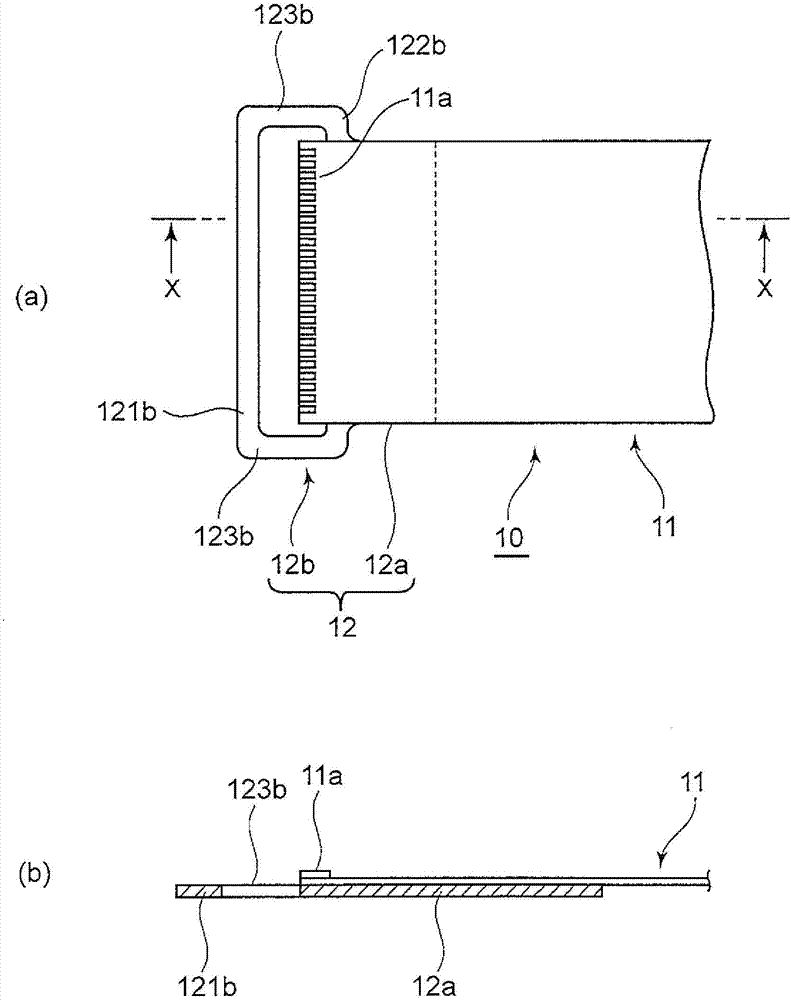

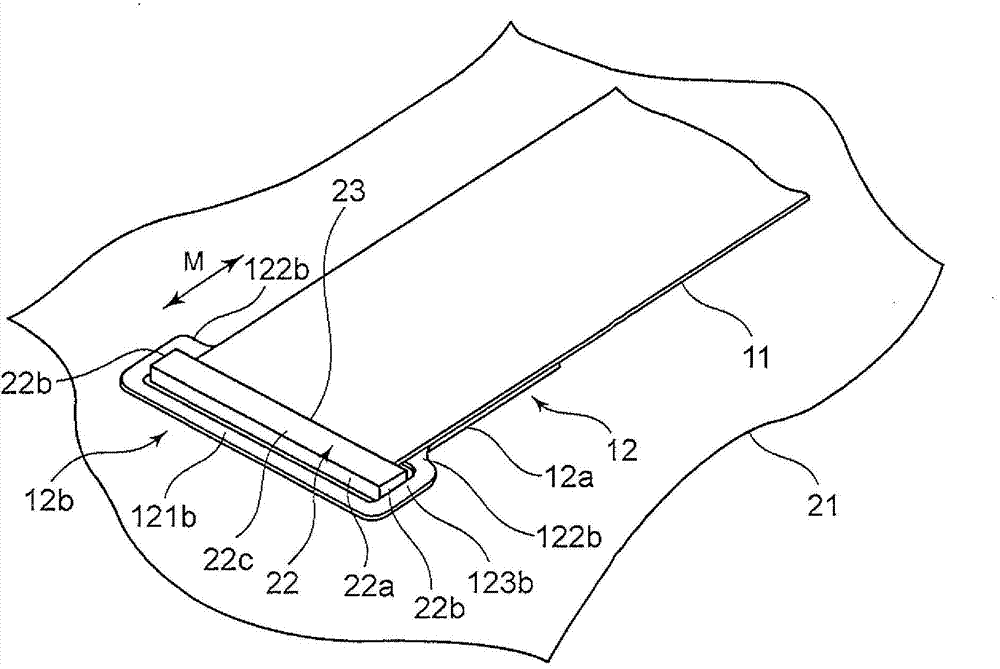

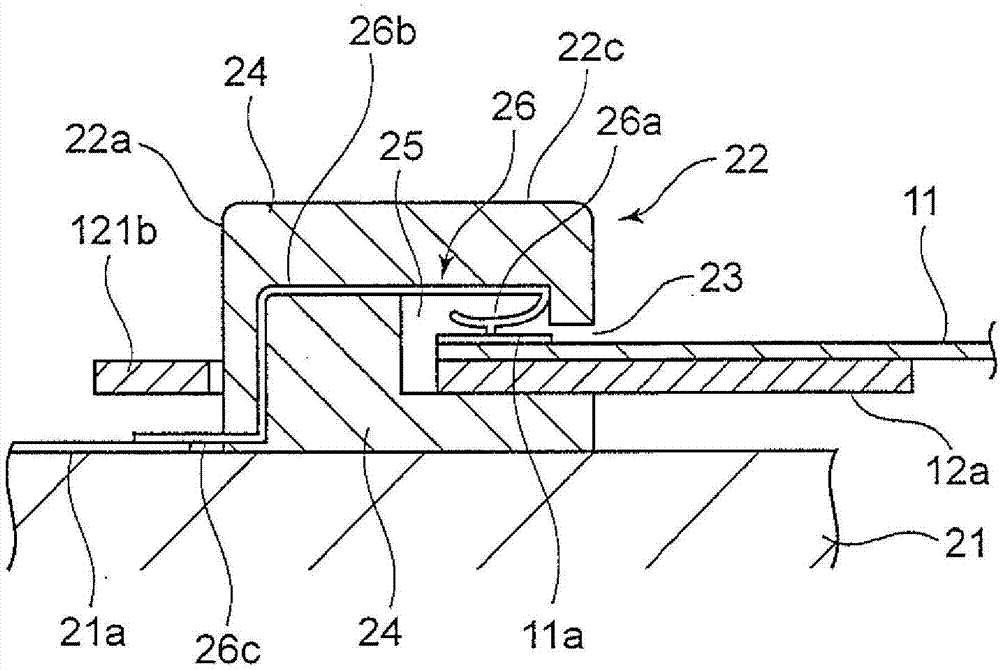

[0025] refer to Figure 1 to Figure 6 , the cable with a reinforcing plate and the reinforcing plate according to the first embodiment of the present invention will be described.

[0026] Such as figure 1 As shown, the cable 10 with a reinforcing plate according to this embodiment has a flat cable 11 made of, for example, FFC, and a reinforcing plate 12 fixedly attached to the front end region of the flat cable 11 . Here, the reinforcement plate 12 includes: a support plate 12a supporting one of the front and rear surfaces of the flat cable 11; and an elastically deformable engaging arm 12b connected to the support plate 12a. In addition, on the other surface of the front end portion of the flat cable 11, for example, a connection terminal 11a is formed.

[0027] The engagement arm 12b has an arm front end portion 121b engaged with a front end portion of the connector as described later, and an arm base end portion 122b protruding left and right from both side ends of the su...

no. 2 approach

[0054] Next, refer to Figure 7A cable with a reinforcing plate according to a second embodiment will be described. In the second embodiment, the shape of the engaging arm of the reinforcing plate is different from the annular shape in the first embodiment.

[0055] Such as Figure 7 As shown, in the cable with a reinforcing plate of this embodiment, the reinforcing plate 42 is fixedly attached to the front end region of the flat cable 11 as described in the first embodiment. Here, the reinforcement plate 42 includes: a support plate 42a supporting one of the front and rear surfaces of the flat cable 11; and an elastically deformable engaging arm 42b connected to the support plate 42a.

[0056] Also, the engaging arm 42b has a first arm piece 421b and a second arm piece 422b so as to engage with the connector front end portion 22a and the connector side end portion 22b of the connector 22 surface-mounted on the main board 21 . Here, the first arm piece 421b and the second a...

no. 3 approach

[0060] Next, refer to Figure 8 A cable with a reinforcing plate according to a third embodiment will be described. In the third embodiment, unlike the first embodiment, the engaging arm of the reinforcing plate is formed in a structure that partially covers and contacts the upper end of the connector.

[0061] Such as Figure 8 As shown, in the cable with a reinforcing plate of this embodiment, the reinforcing plate 52 is fixedly attached to the front end region of the flat cable 11 as described in the first embodiment. The reinforcement plate 52 includes: a support plate 52a supporting one of the front and rear surfaces of the flat cable 11; and an elastically deformable engaging arm 52b connected to the support plate 52a.

[0062] The engaging arm 52b has an arm front end portion 521b engageable with the connector front end portion 22a of the connector 22, and an arm base end portion 522b protruding left and right from both side ends of the support plate 52a. Furthermore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com