Cutting longitudinal flow threshing separation and cleaning device

A technology of threshing separation and cleaning device, which is applied in the direction of threshing equipment, application, agricultural machinery and implements, etc. It can solve the problems of increased total loss rate and impurity rate of the machine, prone to blockage failure, complex structure, etc., and achieves grain loss. Low rate and impurity content, low power consumption for threshing and separation, and strong threshing and separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

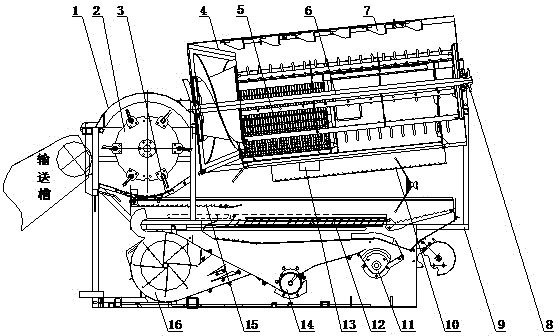

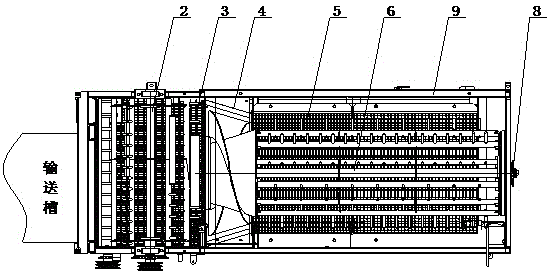

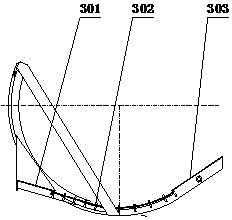

[0025] Such as figure 1 and figure 2 As shown, the cutting and longitudinal flow threshing separation and cleaning device mainly includes a cutting and longitudinal flow double-drum threshing and separation device, a conveying device for extruded material, a double-air duct air screen cleaning device, a grain residue conveying device, a transmission system 8 and a frame 9 , wherein the tangential longitudinal axial flow double-drum threshing separation device is mainly composed of a tangential flow threshing separation device and a longitudinal axial flow threshing separation device. The cutting flow threshing separation device mainly includes the cutting flow threshing drum 2, the cutting flow concave plate 3 and the cutting flow top cover 1; the longitudinal axial flow threshing separation device mainly includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com