Tissue cutting mechanism of tissue device

A technology for cutting paper and paper towels, which is applied in the field of induction paper towels, which can solve the problems of fragile blades and unstable paper cutting, and achieve the effect of smooth paper cutting and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The paper towel cutter paper cutting mechanism claimed in the present invention will be described in detail below in conjunction with the accompanying drawings.

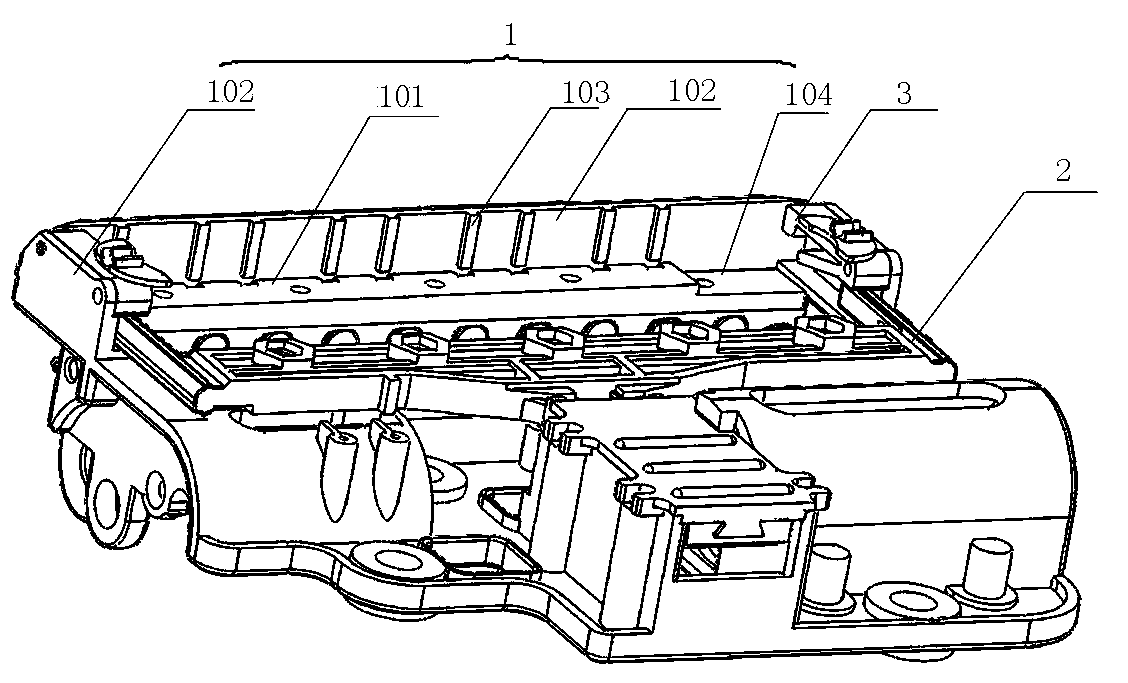

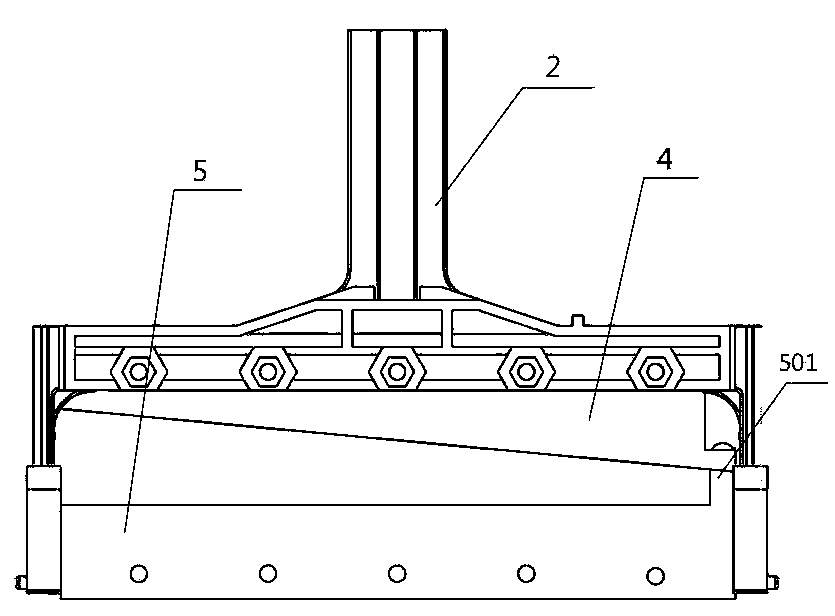

[0014] A paper towel cutter paper cutting mechanism according to the present invention, such as figure 1 , 2 As shown, it includes an electric paper cutting mechanism, which includes a moving blade 4 and a static blade 5, the static blade 5 is fixed on the support 1, the moving blade 4 is fixed on the knife holder 2, and the front end of the moving blade 4 is left The side is wider than the slope on the right, and the front end of the support 1 forms a support surface 101 for supporting the stationary blade 5. The front end and left and right side edges of the support surface 101 are perpendicular to the support surface to form a support wall 102, and the lower surface of the support surface 101 is a plane The height of the upper surface of the support surface 101 gradually increases from the left to the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com