Printer automatic paper cutter structure

A paper cutter and printer technology, applied in printing devices, printing, etc., can solve problems affecting performance, paper cutting, and limited cutting life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

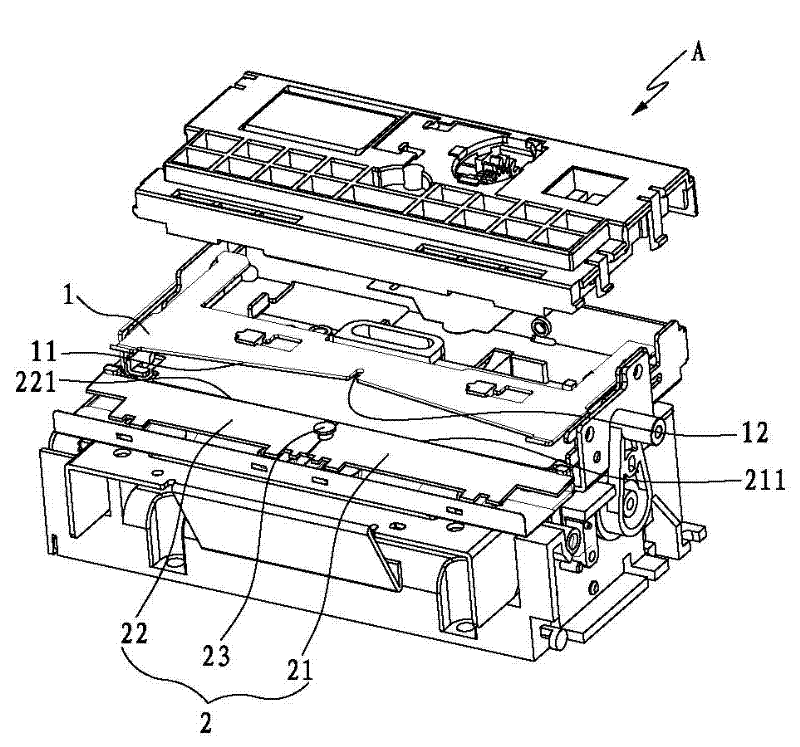

[0022] like Figure 3 to Figure 9 As shown, the present invention discloses a printer automatic paper cutter structure, which is arranged at the paper outlet of the printing module A of the printer, which includes an upper cutting blade 1 located above the paper outlet and a lower blade 1 located below the paper outlet. Cutting blade 2, the upper and lower cutting blades are relatively movable; the key of the present invention is:

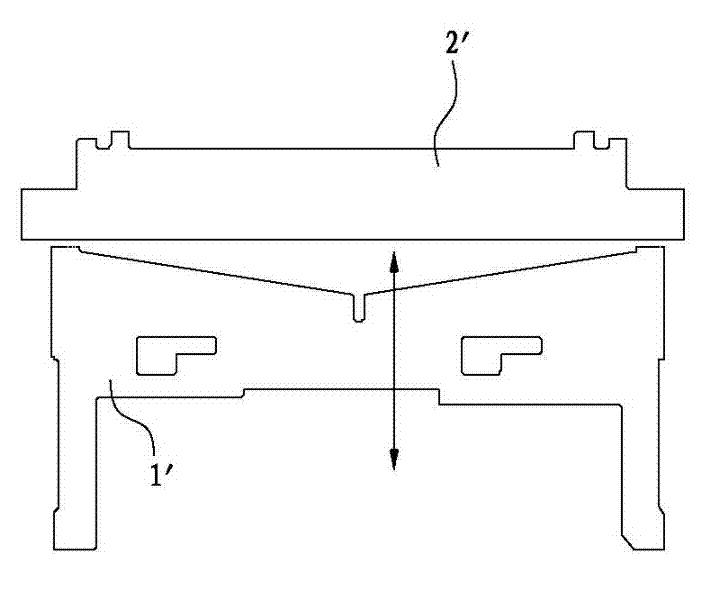

[0023] The lower cutting blade 2 is composed of a lower left cutting blade 21 and a lower right cutting blade 22, and the butt joint between the lower left cutting blade 21 and the lower right cutting blade 22 is supported and connected by supporting nails 23.

[0024] Wherein the cutting edge 11 of the upper cutting blade 1 forms a "V"-shaped gap from its center to both ends, and the cutting edges 211, 221 of the lower left cutting blade 21 and the lower right cutting blade 22 are in a straight line.

[0025] Cooperate Figure 6 to Figure 9 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com