Large-size low temperature cofired ceramic (LTCC) substrate sintering process

A large-size, substrate technology, applied in the field of large-size LTCC substrate sintering process, can solve problems such as cracks, deformation, warpage, etc., to achieve uniform heating, stable sintering curve, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

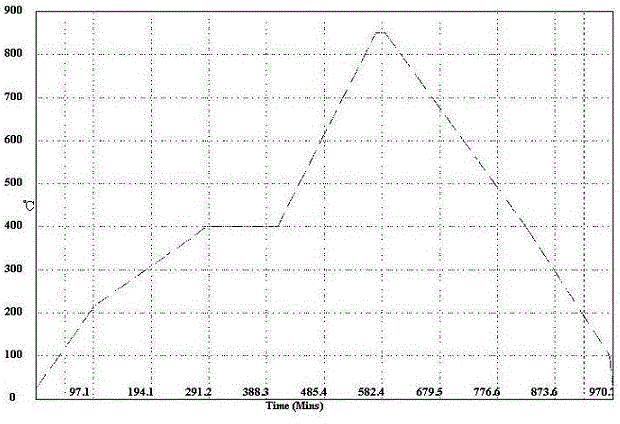

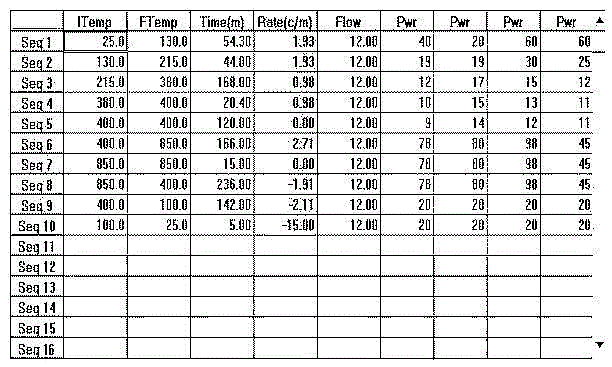

[0022] combine figure 1 and figure 2 , by setting multiple initial heating periods and debinding periods, and adjusting the time, speed and power parameters of each temperature range in the sintering curve, a suitable sintering curve can be obtained to ensure that the debinding of the large-size LTCC substrate is sufficient during the sintering process, and the substrate after sintering Good flatness.

[0023] The aluminum oxide sintered support with a size of 250mm×250mm×5mm is used in the sintering process of the large-sized LTCC substrate to support the large-sized LTCC substrate. The aluminum oxide sintered support is a plate with an area larger than the large-sized LTCC substrate. There...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com