Rotating bending fatigue test device and method with axial load control function

A bending fatigue and axial load technology, applied in the direction of using a stable bending force to test the material strength, using a stable tension/pressure test to test the material strength, using a repetitive force/pulse force to test the material strength, etc. Applying average load and other issues to achieve the effect of simple structure, low manufacturing and use costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

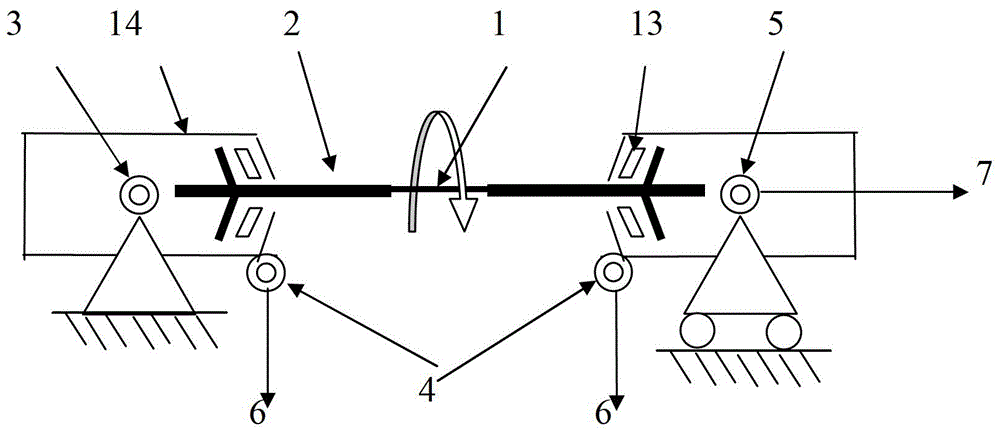

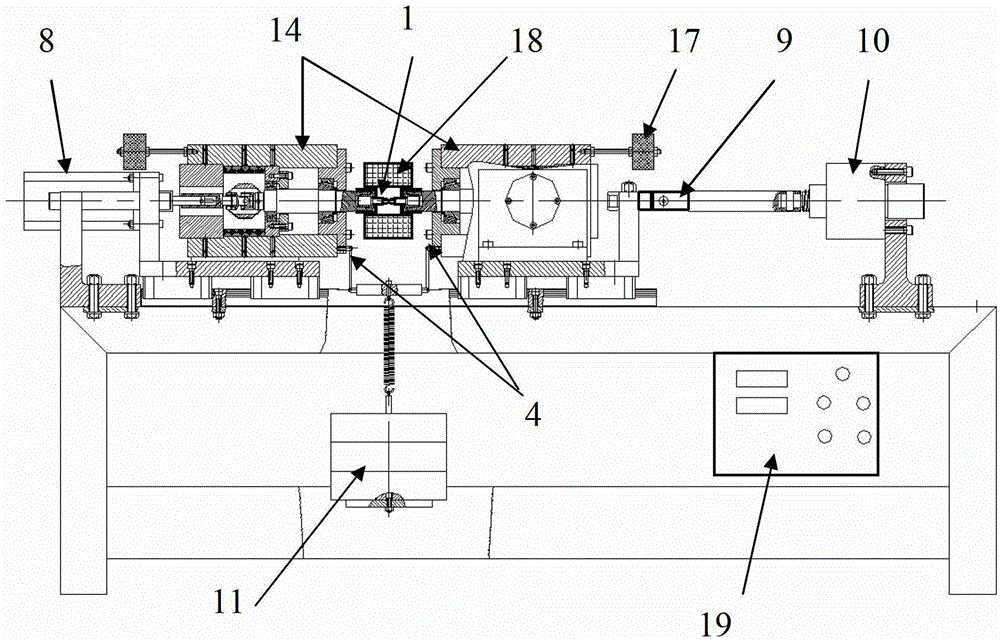

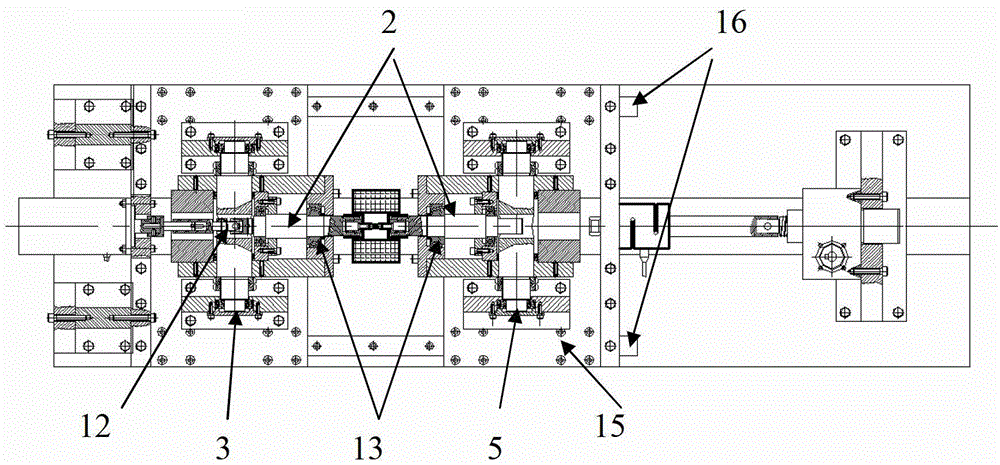

[0044] like figure 1 As shown in the device, its basic structure is a four-point bending force-bearing structure. The device includes: a test sample 1, two sample fixed shafts 2, two tapered roller bearings 13, two fixed sleeves 14, and hinge fulcrums 3, 4, 5 on the fixed sleeve 14. The test sample 1 is fixed in the middle of the sample fixing shaft 2, and the test sample 1 and the sample fixing shaft 2 rotate around their own axes. The sample fixing shaft 2 is installed in the middle of the fixing sleeve 14 through a tapered roller bearing 13 . The fixed loading hinge fulcrum 3 and the axial loading hinge fulcrum 5 on the fixed sleeve 14 support the weight of the entire four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com