Method for controlling inductance discharge

A technology of inductive discharge and control method, which is applied in the electronic field and can solve problems such as uncontrollable, uncontrollable discharge volume, and low discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

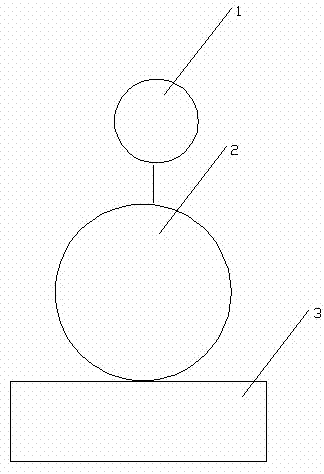

[0008] The present invention will be further described below via accompanying drawing:

[0009] as attached figure 1 As shown, the control method of inductive discharge is first embedded with a thread processing chip 1 with a blocked inductive discharge module, and another built-in programmable logic controller PLC2 and inductive discharge detector 3 that are in contact with the blocked inductive discharge module; When the chip 1 is connected to the inductive discharge device and turned on, it immediately drives the programmable logic controller PLC2 in parallel with the control and detection feedback of the inductive discharge detector, realizing the control of the inductive discharge control method to process the discharge amount according to the preset method.

[0010] When the thread processing chip 1 is connected to the inductive discharge device and turned on, the programmable logic controller PLC2 is then driven in parallel with the control and detection feedback of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap