Blanking device of nonuniform section iron core in progressive die

A progressive die and section technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as low efficiency, poor product quality stability, difficulty in meeting product use requirements, etc., and achieve the goal of improving stability and rationalization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

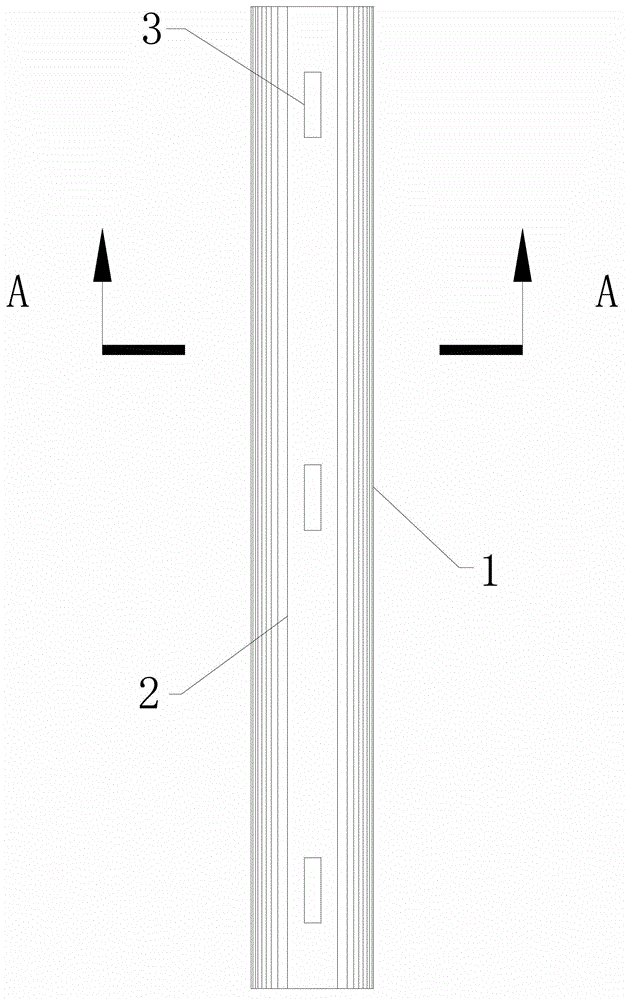

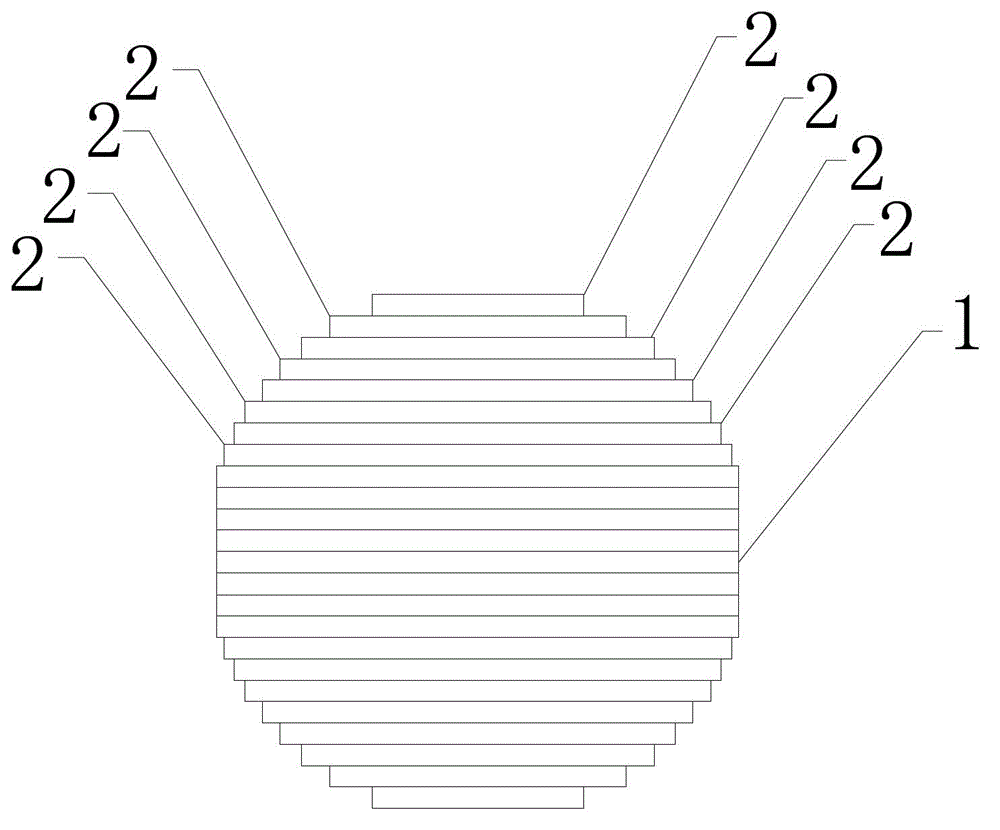

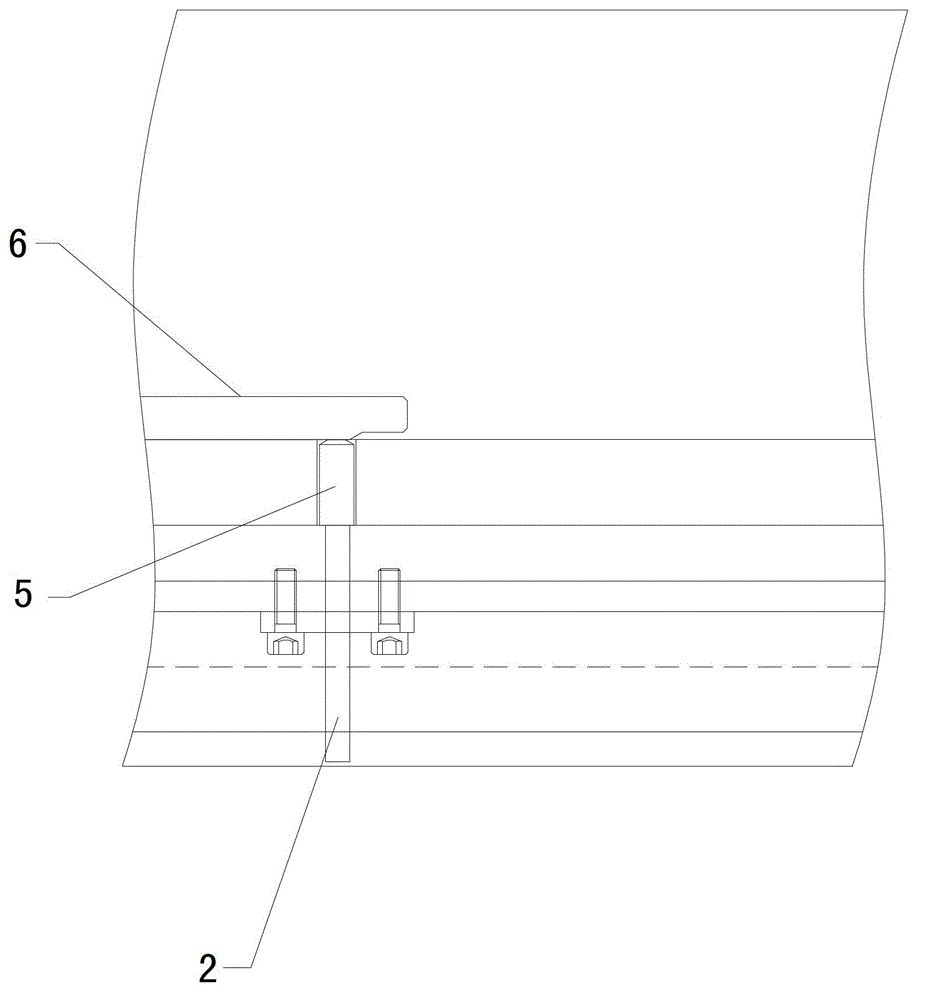

[0015] like Figure 1-4 As shown in the figure, a punching device for a non-uniform cross-section iron core in a progressive die according to an embodiment of the present invention includes a plurality of stacked first punches 1, and two sides of the plurality of first punches 1 are respectively provided with eight punches. The lengths of the eight second punches 2 decrease in turn. The two second punches 2 with the longest lengths are respectively arranged on the top and bottom surfaces of the first punches 1. The first punches The length of 1 is greater than the length of the longest second punch 2, the first punch 1 and the second punch 2 are provided with three riveting points 3, the first punch 1 is provided with a pressure rod 4, and the The bottom end protrudes from the bottom surface of the first punch 1 , the second punch 2 is provided with a punch head 5 , and the punch head 5 is provided with a movable punch plate 6 .

[0016] The optimal lengths of the eight secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com