High-intensity steel fireproof channel door

A passage door, high-strength technology, applied to fire doors, mining equipment, mining equipment, etc., can solve problems such as slow opening, achieve uniform door gaps, facilitate evacuation and escape, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and implementation.

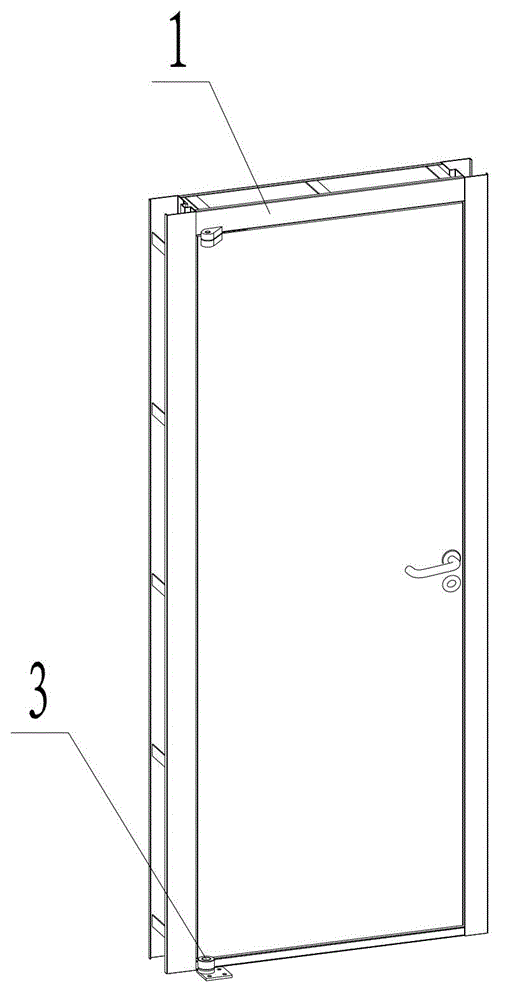

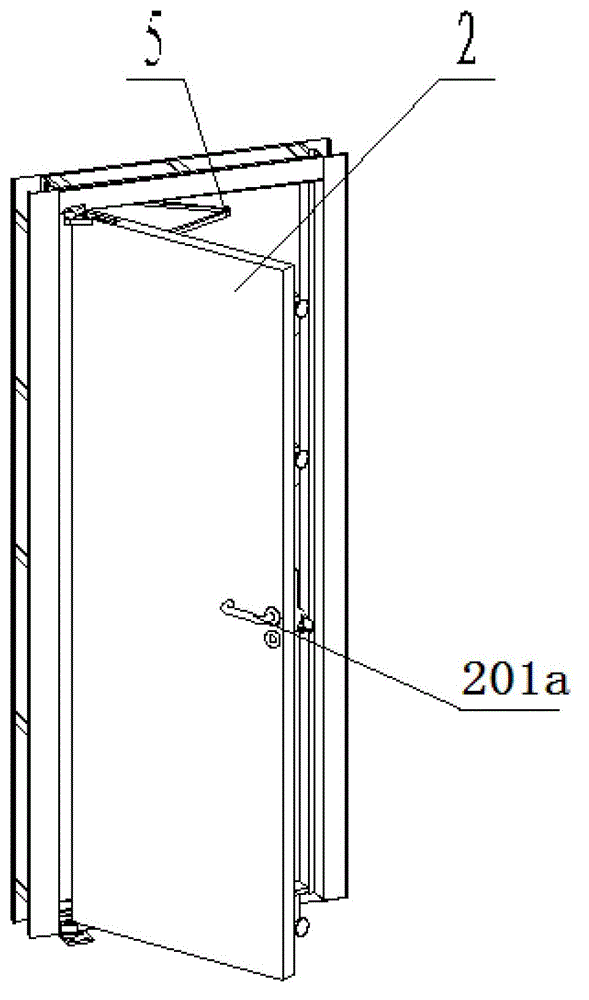

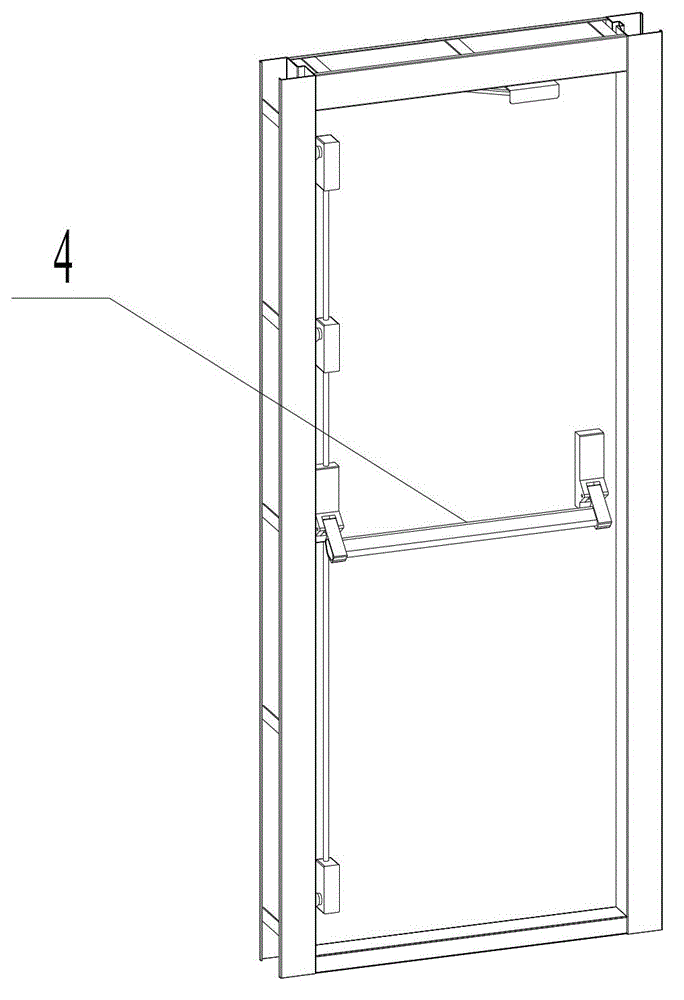

[0025] as attached Figure 1-8 As shown, a high-strength steel fire-proof access door includes a door frame 1 and a door leaf 2, and the door frame 1 and the door leaf 2 are connected by a sky-ground hinge 3 to form an access door, wherein the door frame 1 includes a hinge side mullion 101 , the upper frame 102, the lock side mullion 103 and the threshold 104, the hinge side mullion 101, the upper frame 102, the lock side mullion 103 and the threshold 104 are sequentially fixedly connected to form a square door frame 1, and the hinge side mullion 101 and the upper frame 102 is connected with a groove on one side, and a double fireproof sealing strip 105 is installed in the groove, and a reinforcing seal 106 is installed on the side connecting the lock side mullion 103 and the upper frame 102, and the hinge side mullion 101 and the lock Channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com