Improved floor heating modular structure

A modular structure, floor heating technology, applied in building structure, household heating, space heating and ventilation details, etc., can solve the problems of waste of electric resources, inability to store thermal energy, maintain temperature, etc., to promote blood circulation, The effect of speeding up the cooling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

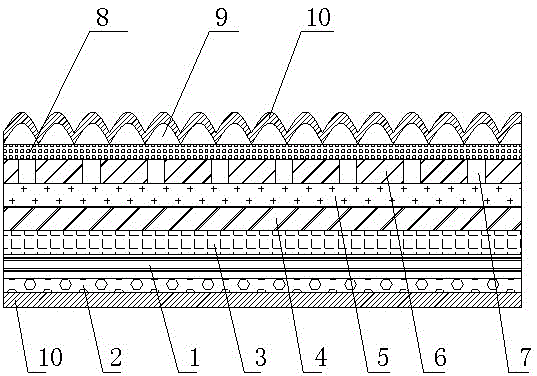

[0015] Such as figure 1 As shown, an improved floor heating module structure of the present invention includes a heating pipe layer 1, the lower end of the heating pipe layer 1 is provided with an insulating layer 2, the upper end of the heating pipe layer 1 is provided with a heat storage layer 3, and the upper end of the heat storage layer 3 A metal layer 4 is provided, the upper end of the metal layer 4 is provided with a far-infrared ceramic layer 5, the upper end of the far-infrared ceramic layer 5 is provided with a heat dissipation layer 6, the heat dissipation layer 6 is provided with a heat dissipation hole 7, and the upper end of the heat dissipation layer 6 is provided with a floor material layer 8 , the floor material layer 8 is provided with bumps 9, the upper and lower ends of the floor material layer 8 and the insulation layer 2 are provided with protective films 10, the floor material layer 8 is made of concrete, the heating pipe layer 1 is wave-shaped, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap