Unloading device for guide rail of high speed elevator

A high-speed elevator and unloading device technology, applied in the field of elevators, can solve problems such as guide rail bending deformation, guide rail deformation, and poor comfort in high-speed elevator operation, so as to ensure the safety of passengers and avoid bending deformation under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings and specific embodiments.

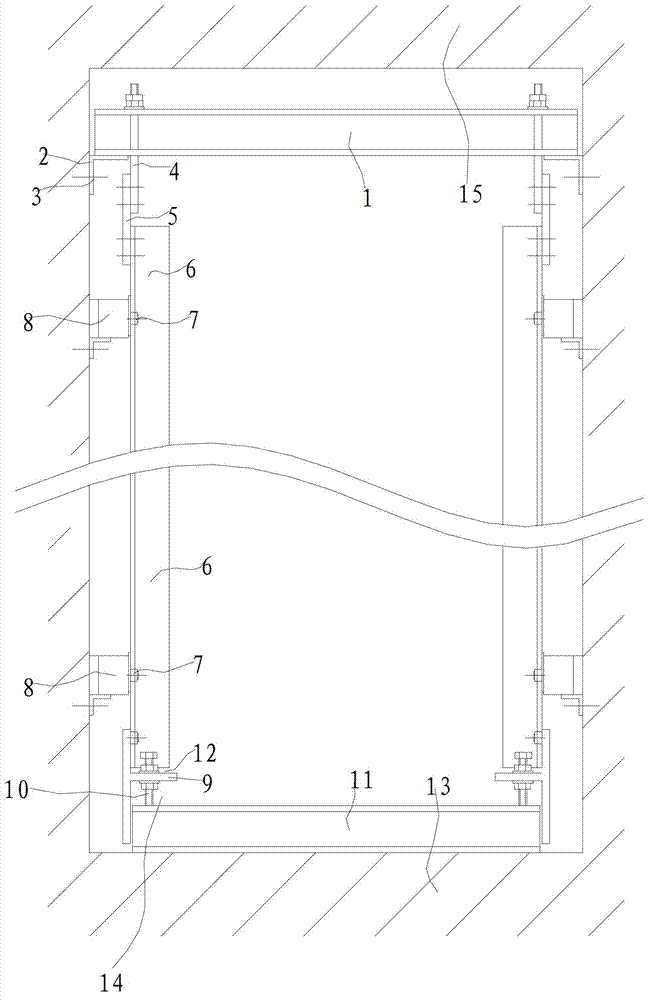

[0020] High-speed elevator guide rail unloading device, such as figure 1 As shown, a load-bearing component 1 is installed on the top 15 of the elevator hoistway, and the elevator guide rail 6 is suspended below the load-bearing component 1 so that the main force is transferred to the upper load-bearing component 1. Wherein, the load-bearing component 1 may be an I-beam or similar structurally strong component with good load-bearing performance. The load-bearing component 1 may be fixed at the top of the hoistway by means of expansion bolts 3 and angle steel 2.

[0021] Preferably, a tie rod 4 is installed on the load-bearing component 1, the elevator guide rail 6 is fixed to the tie rod 4 through a guide rail connecting plate 5, and the main weight of all elevator guide rails 6 of the entire elevator is through the tie rod 4 and the guide rail connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com