Method and system for generating three-dimensional operation instruction for ship section manufacture

A technology of operation instructions and segmented manufacturing, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that operation instructions cannot effectively improve manufacturing efficiency and construction quality, and achieve shortening ship construction cycle and improving The level of informatization and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

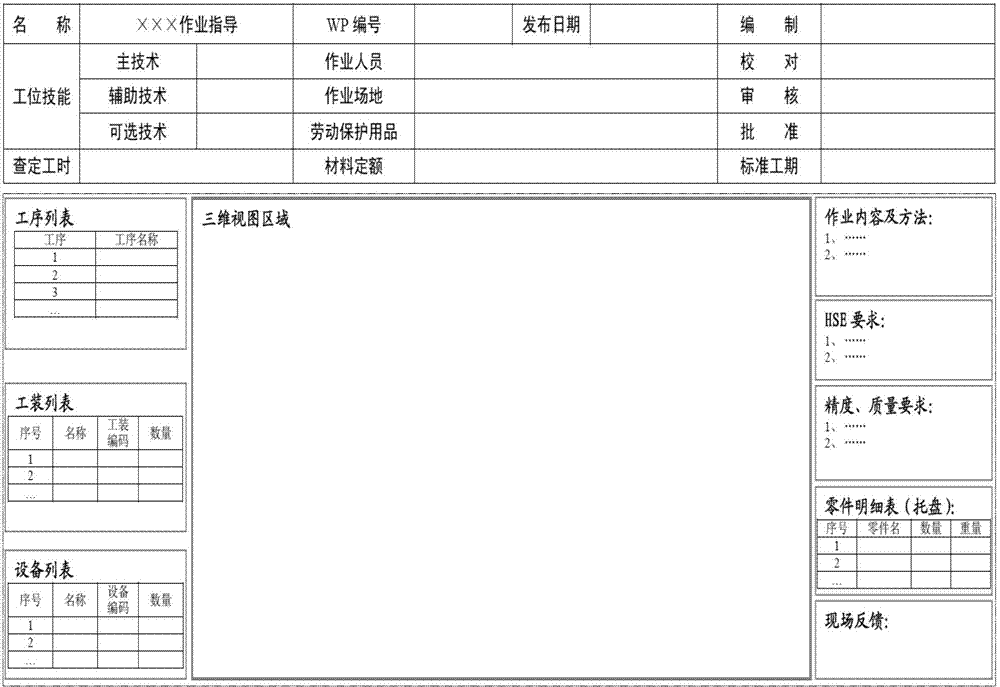

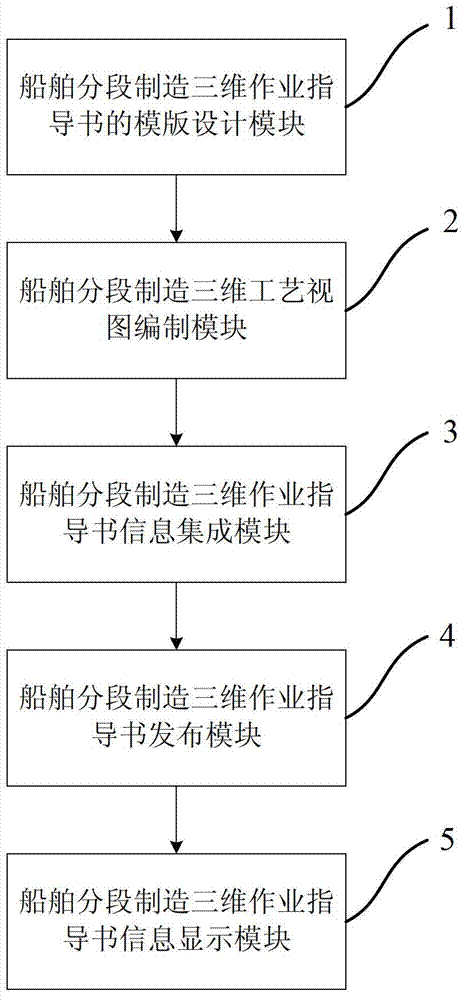

[0053] The present invention provides a system for generating a three-dimensional operation instruction book for segmental manufacturing of ships. The generation system for the three-dimensional operation instruction book for block manufacturing of ships is as follows: figure 1 As shown, it includes: template design module 1 of the 3D operation instruction for ship block manufacturing, 3D process view compilation module for ship block manufacturing 2, information integration module for 3D operation instruction book for ship block manufacturing 3, 3D operation instruction for ship block manufacturing The book release module 4, and the information display module 5 of the three-dimensional operation instruction book for ship block manufacturing.

[0054] The ship block manufacturing 3D operation instruction template design module 1 is used to input the ship block 3D model and manufacturing process requirements, design the ship block manufacturing 3D operation instruction template,...

Embodiment 2

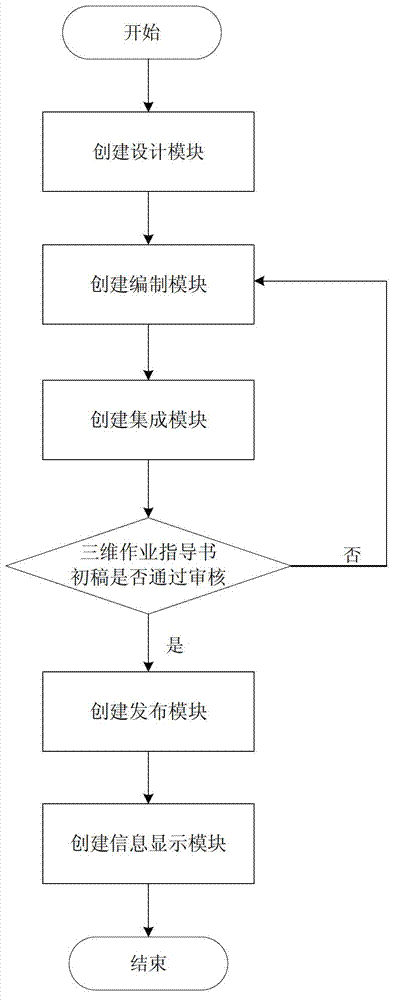

[0061] This embodiment provides a method for generating a three-dimensional operation instruction book for sub-manufacturing of ships. The method for generating the three-dimensional operation instruction book is as follows: image 3 shown, including:

[0062] The step of creating the template design module of the 3D operation instruction book for ship segment manufacturing, making the design module input the 3D model of the ship segment and the manufacturing process requirements, and according to the division of the ship segment guidance organizational structure, for each operation area of the ship segment manufacturing The characteristics and requirements of the three-dimensional work instruction book template design, determine the style and content of the three-dimensional work instruction book template; the three-dimensional work instruction book template is divided into header area, process area, three-dimensional view area and auxiliary information area. The header are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com