Staple bin assembly and stapler using same

A component and staple cartridge technology, applied in the direction of surgical fixation nails, etc., can solve the problems of affecting the surgical effect, increasing the pain of patients, and poor staple forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

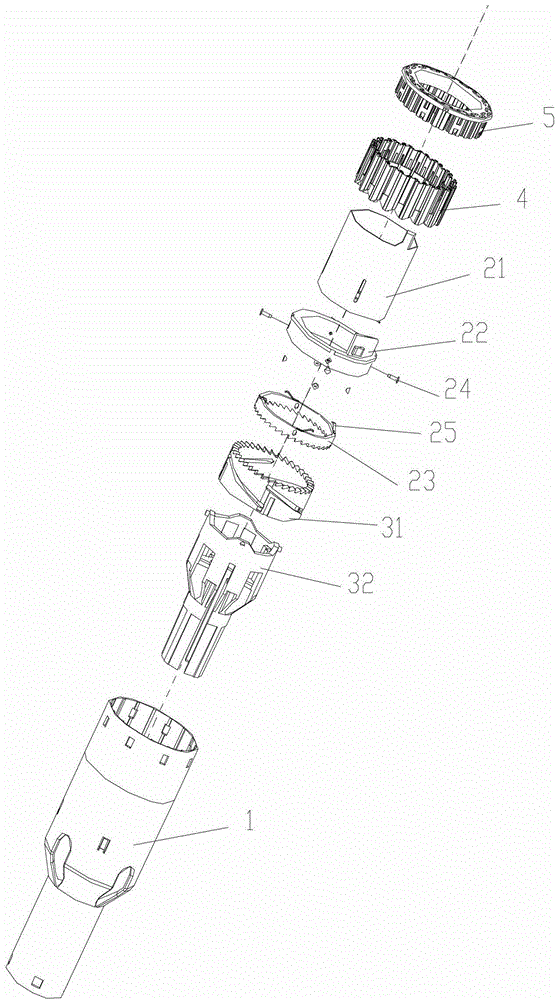

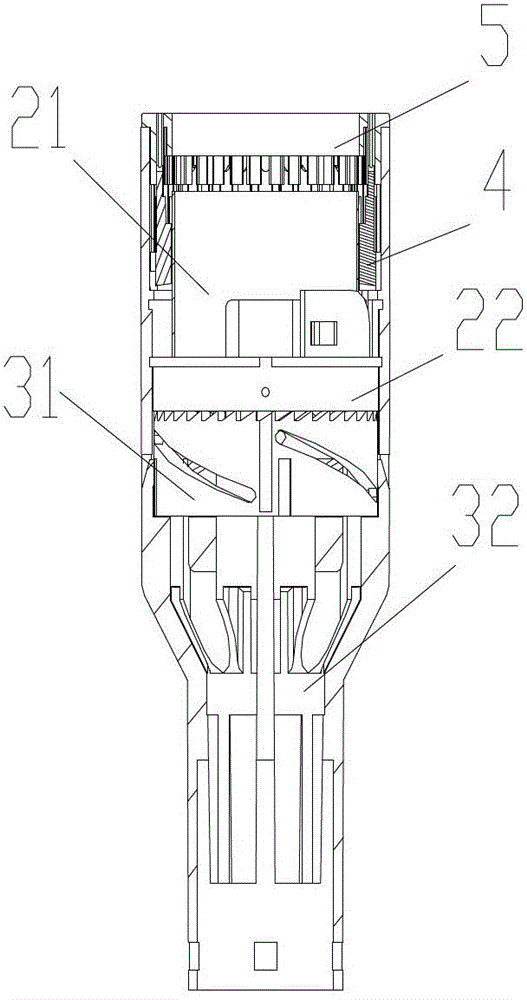

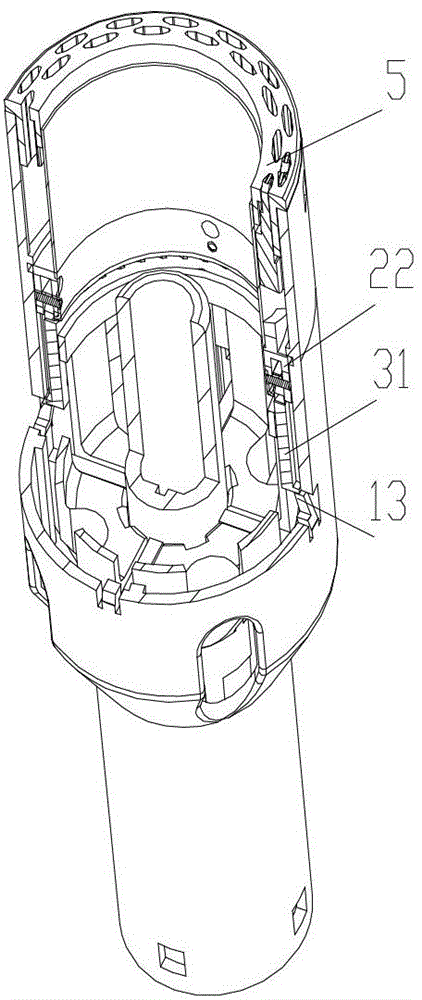

[0031] see Figure 1-3 As shown, a staple cartridge assembly of the present invention includes a staple cartridge cover 1, a staple cartridge 5 fixed on the upper end of the staple cartridge cover 1, a nail pusher 4 installed in the staple cartridge cover 1, a slit assembly and a driving assembly .

[0032] The following up, down, left and right are all based on figure 1 The orientation shown in is a standard description.

[0033] Among them, please refer to Figure 4 As shown, the kerf assembly includes a cutter slider 21 , a nail pusher slider 22 and a cutter gear ring 23 . The lower part of the cutter slider 21 is a cylinder, and the upper end is a cutting head 211. The push nail 4 and the push nail slider 22 can slide up and down and are set on the outside of the cylinder of the cutter slider 21. The push nail 4 is located on the push nail. Slider 22 above. The cutter gear ring 23 is installed on the bottom of the nail pushing slider 22 .

[0034] Please refer to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com