C type steel provided with reinforcement fins for building steel structure

A technology of C-shaped steel and construction steel, applied in truss structures, joists, girders, etc., can solve the problems of design calculation error, damage, calculation model difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] specific implementation plan

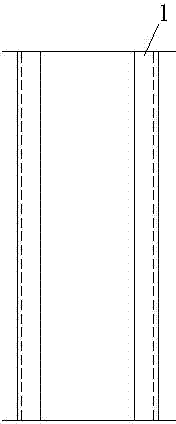

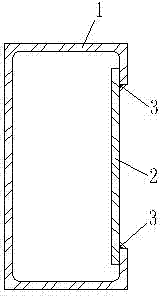

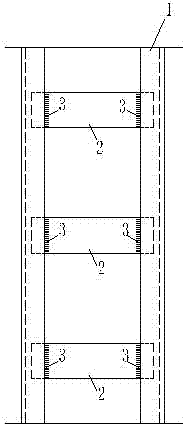

[0006] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing: The present invention adopts sheet material and profile to be connected with C-shaped steel at the opening of C-shaped steel to form C-shaped steel with ribs; image 3 , 4 , use the rib 2 and the C-shaped steel 1 to be intermittently connected through the weld 3 at the opening of the C-shaped steel; the rib is a plate or a profile; see the second embodiment Figure 5 , in order to increase the strength, the ribs can be placed obliquely in one direction; see Example 3 Figure 6 , in order to make the component stress reasonable, the ribs can also be placed obliquely in both directions; see the fourth embodiment Figure 7 , 8 , for the convenience of connecting ribs 4 can be bent; the present invention uses ribs to add to the opening of the C-shaped steel, which can greatly reduce the weight and effectively reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com