Shaft shield

A technology of a shield and a telescopic shield, applied in the field of shields, can solve the problems of easy blockage of the lubricating oil injection port, easy pollution of the surface of the linear track, reduction of the amount of lubricating oil, etc., and achieves a simple structure, reduces direct friction, and prolongs service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

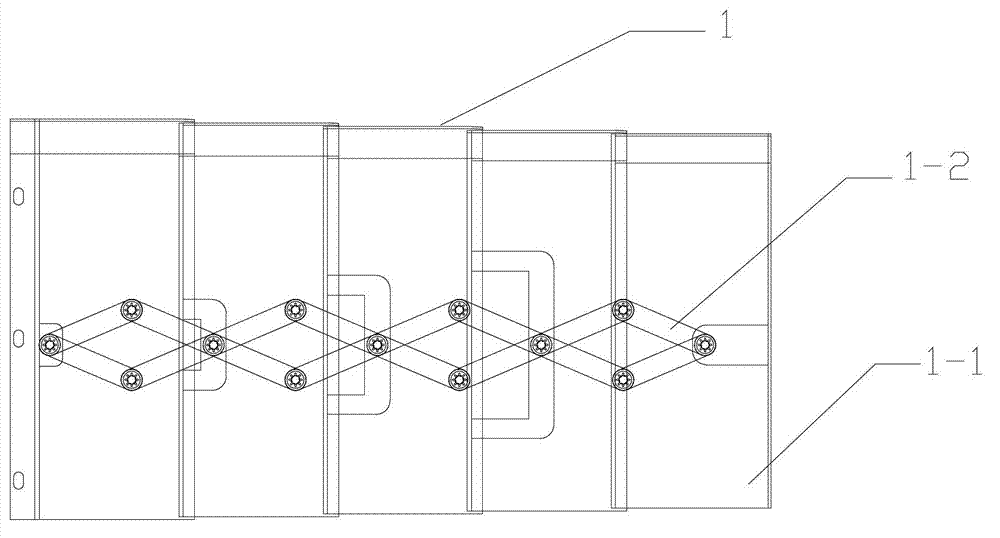

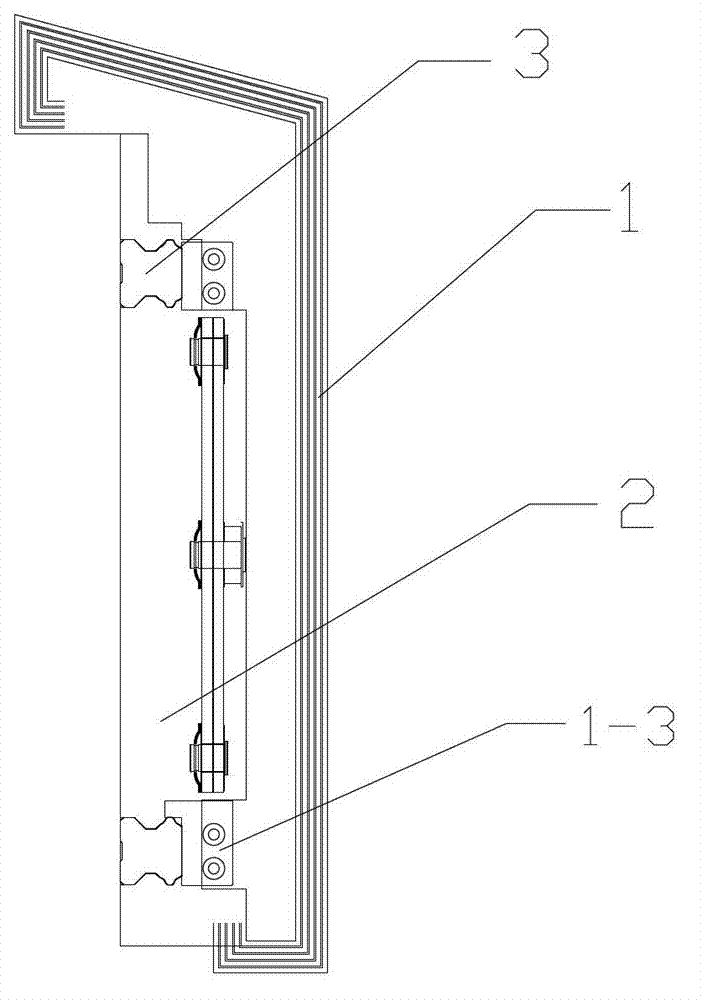

[0014] Example: refer to figure 1 , 2 As shown, a shaft shield includes a telescopic shield 1 and a base 2, and the two sides of the top surface of the base 2 are respectively provided with linear tracks 3 for sliding the telescopic shield, and the telescopic shield 1 includes several rectangular plates 1-1 , the cross stretcher 1-2 and the roller 1-3, the rectangular plates 1-1 are arranged from large to small, the plate and the plate are connected by the cross stretcher 1-2, the roller 1-3 is located under the rectangular plate 1-1 and It can slide on the linear track 3, and by adding rollers 1-3, the direct friction between the telescopic cover 1 and the linear track 3 is reduced, thereby prolonging the service life. The rectangular plate 1-1 is connected with the cross expander 1-2 through screws, which is convenient to install and easy to disassemble, which greatly improves the work efficiency. The rectangular plate 1-1 is made of stainless steel material.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com