Patents

Literature

41results about How to "Reduce direct friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

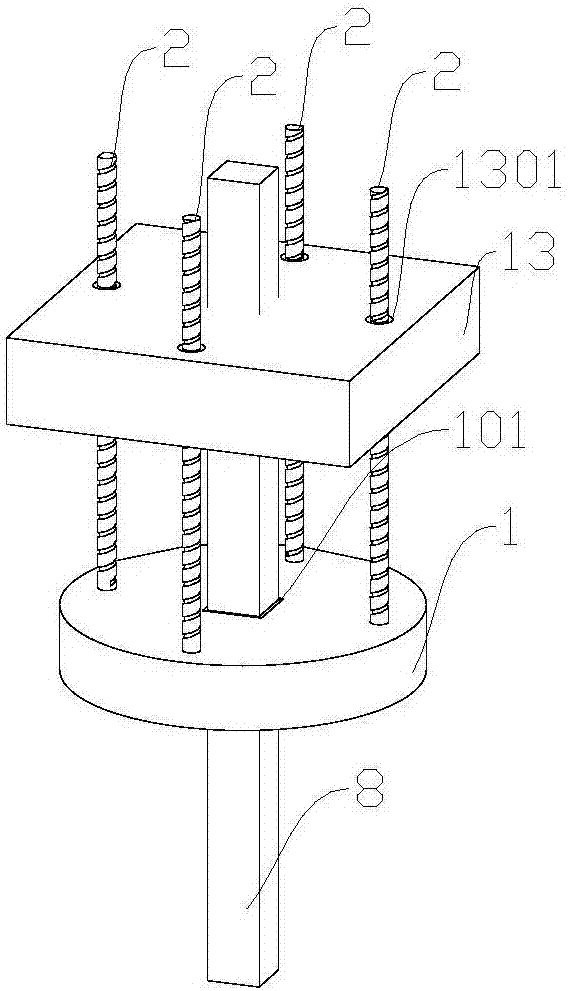

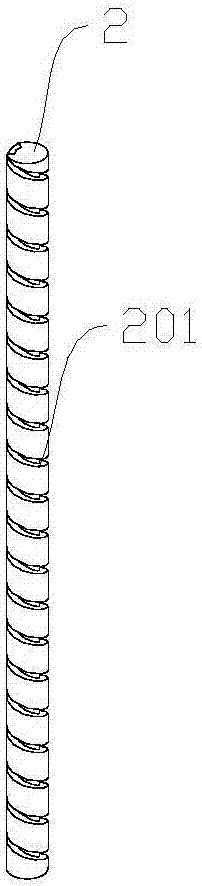

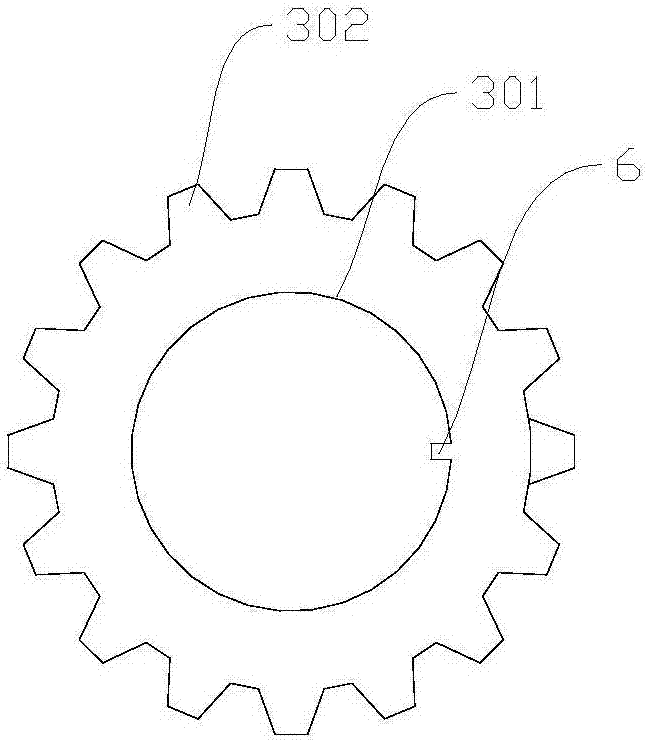

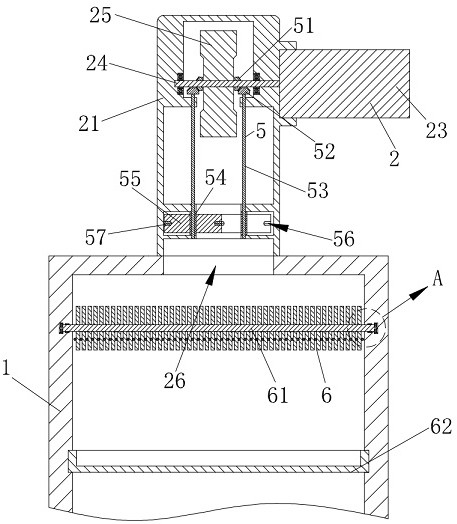

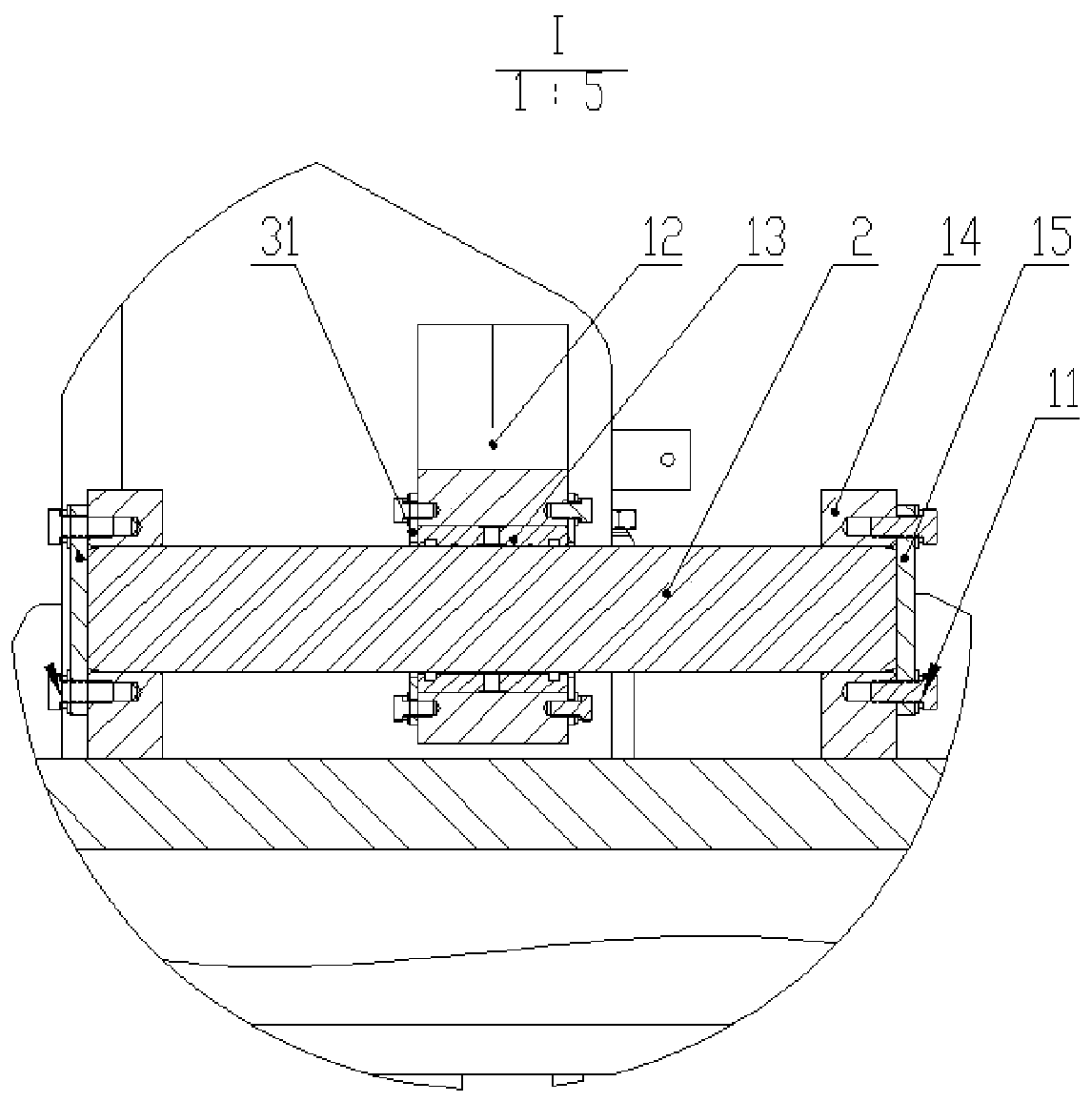

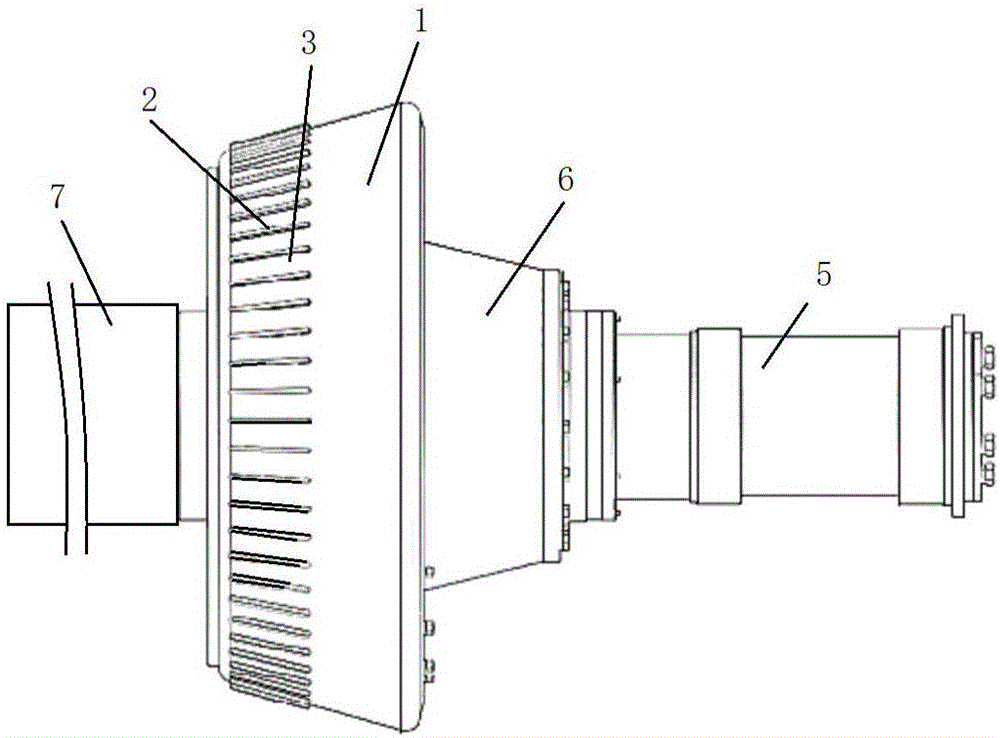

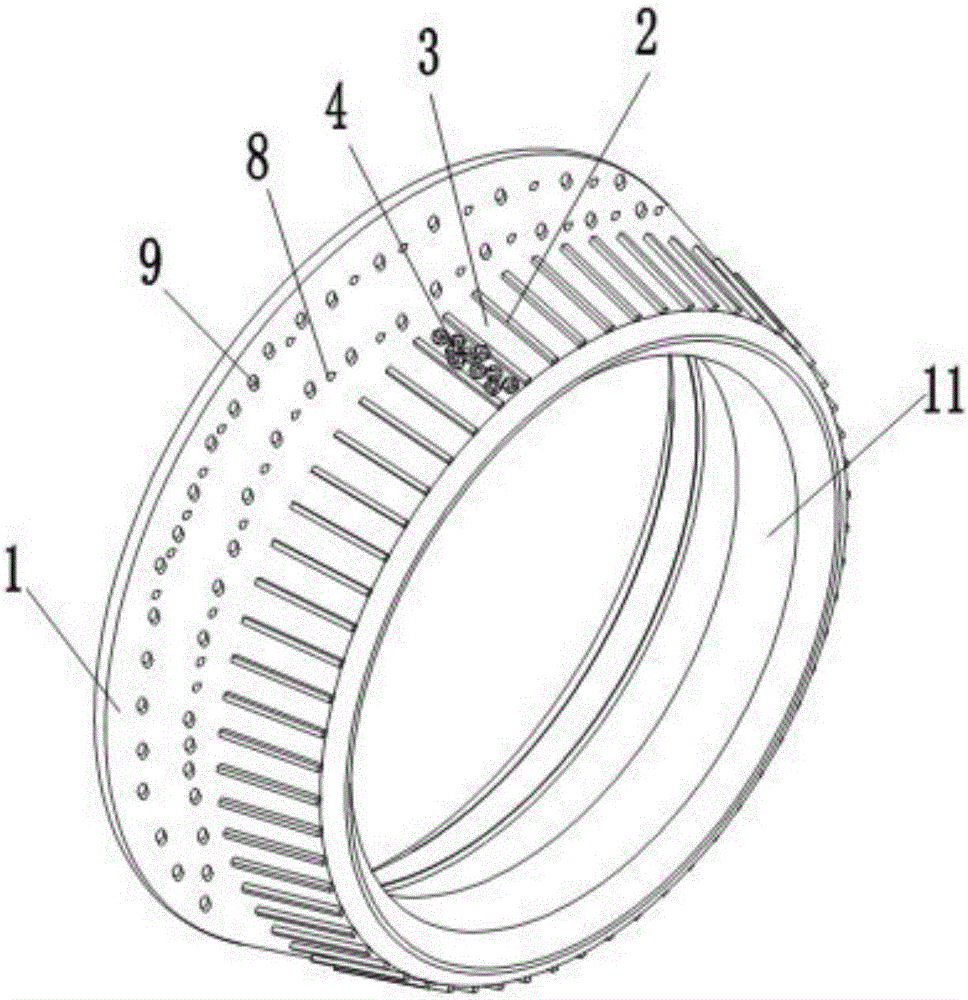

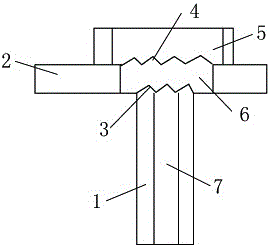

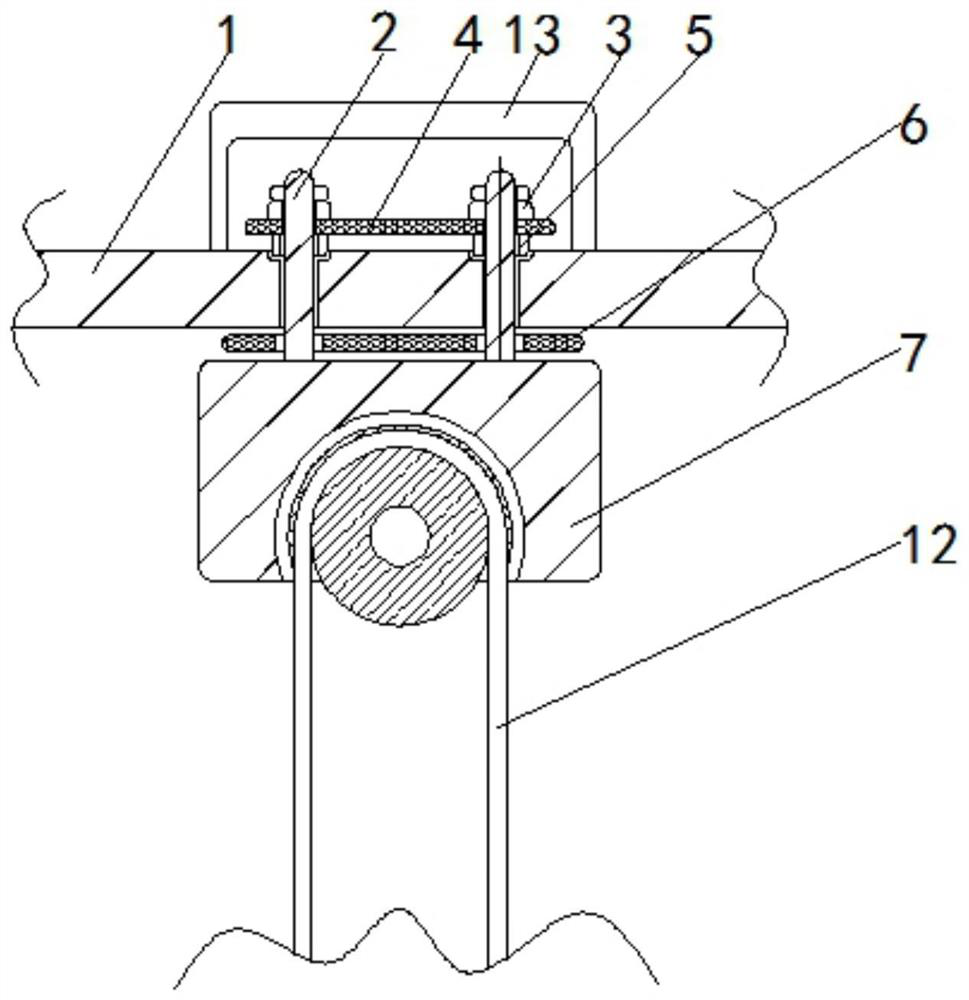

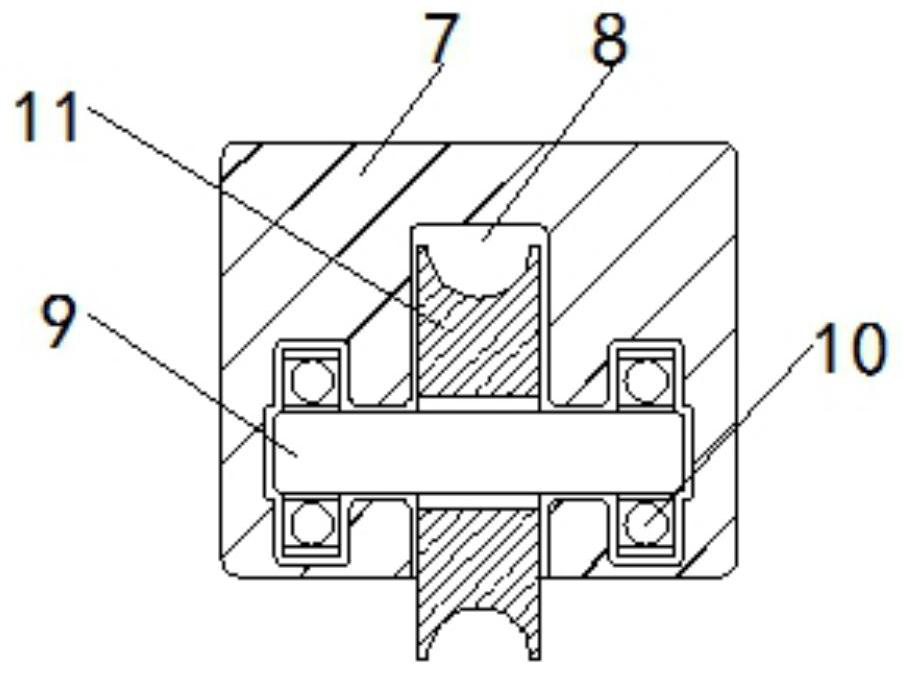

Oscillation buoy power generation device

InactiveCN106949003ASimple structureImprove power generation performanceMachines/enginesEngine componentsBuoyElectric generator

An oscillation buoy power generation device comprises a buoy floating on the sea surface, and power generation assemblies, and further comprises at least one limiting rod installed on the upper end face of the buoy. Spiral grooves are formed around the outer walls of the limiting rods in the length direction of the limiting rods. Each power generation assembly comprises a driving gear installed in cooperation with the corresponding limiting rod, at least one driven gear engaged with the driving gear, and a power generator connected with a hub of each driven gear. Each driving gear comprises a hollow shaft sleeve. Gears are arranged around the outer walls of the hollow shaft sleeves. Transmission pins are arranged on the inner walls of the hollow shaft sleeves. The limiting rods are inserted in the hollow shaft sleeves. The transmission pins are installed in the spiral grooves in an inserted manner and can move along the spiral grooves. According to the novel mechanical oscillation buoy power generation device, the structure of the spiral grooves is designed, rotation, along the spiral grooves, of the driving gears is converted into electric energy of the electric generators through the driven gears, and compared with a traditional wave energy power generation device, the structure is simplified, flexible and reliable, and a stable power generation effect can be achieved.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

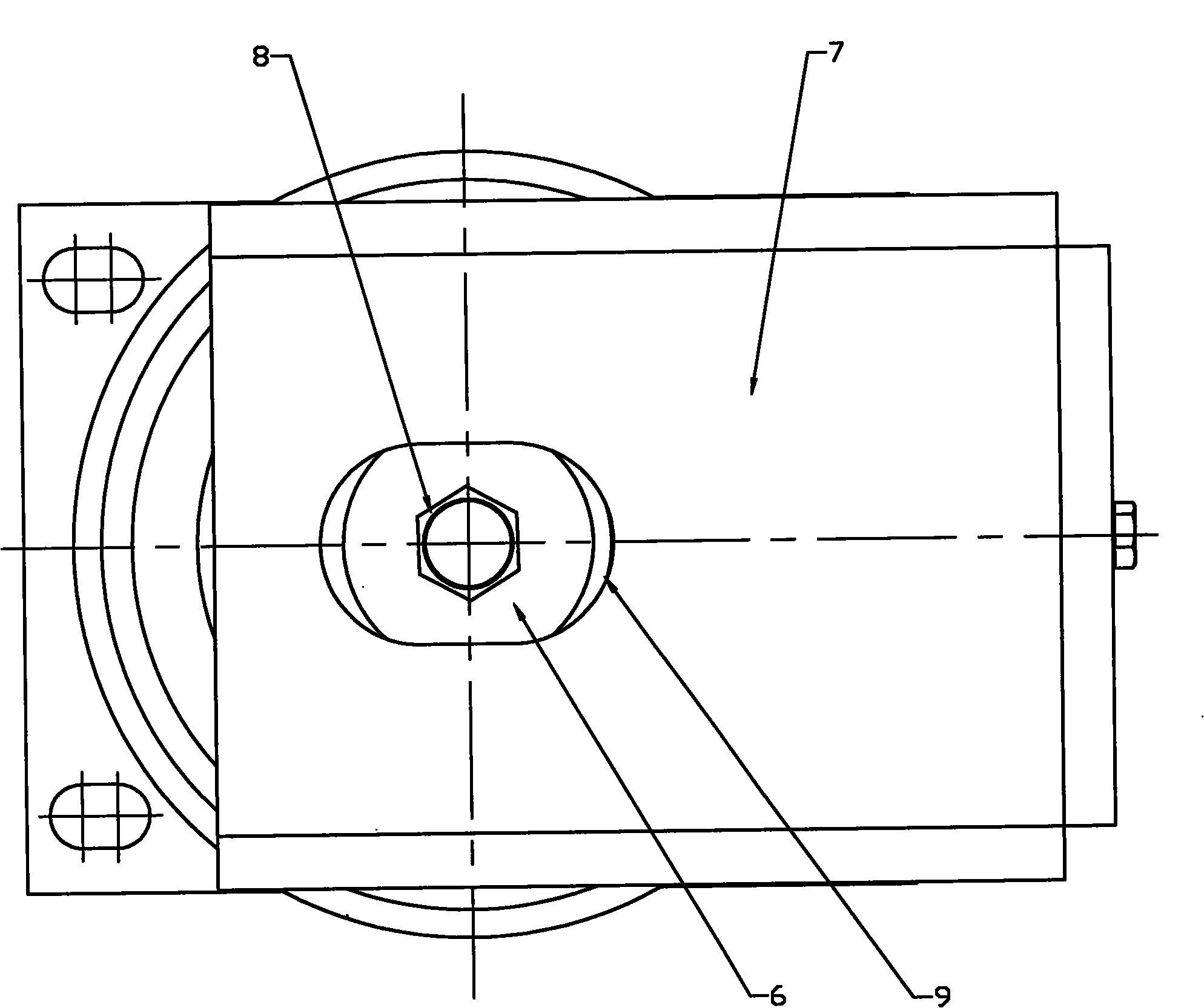

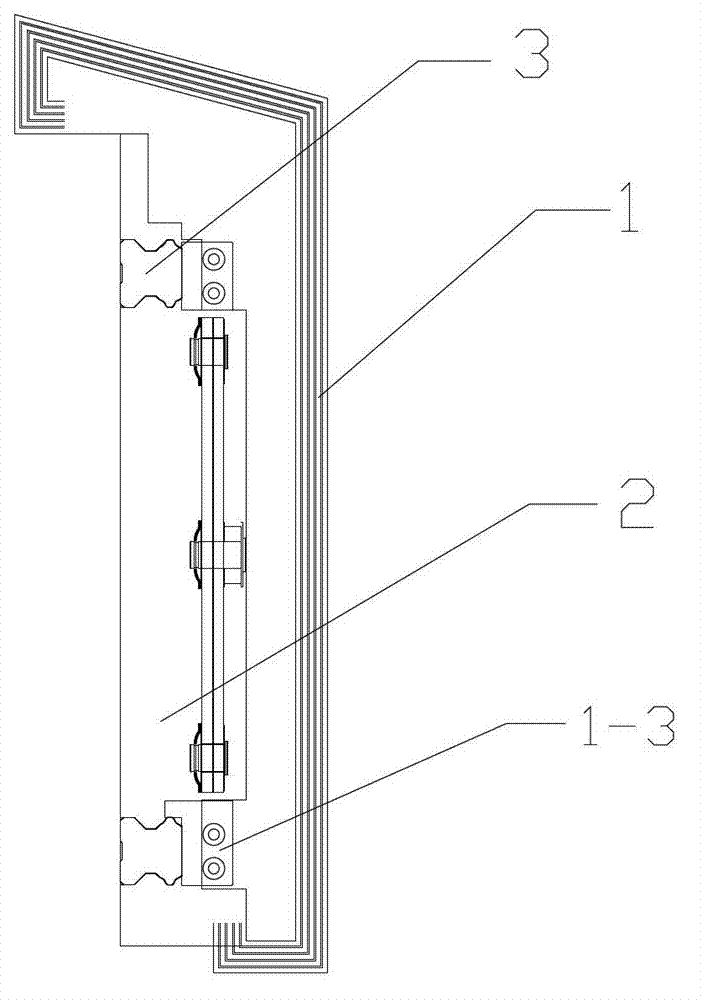

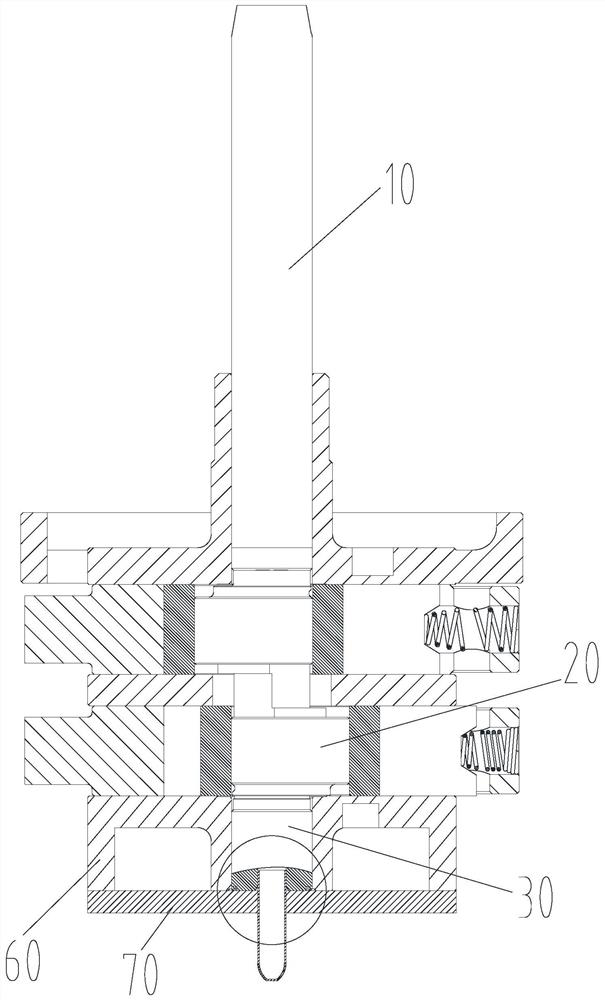

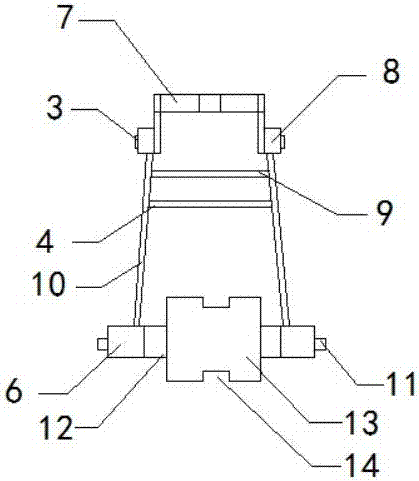

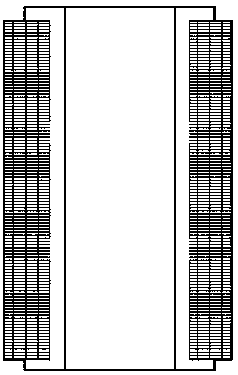

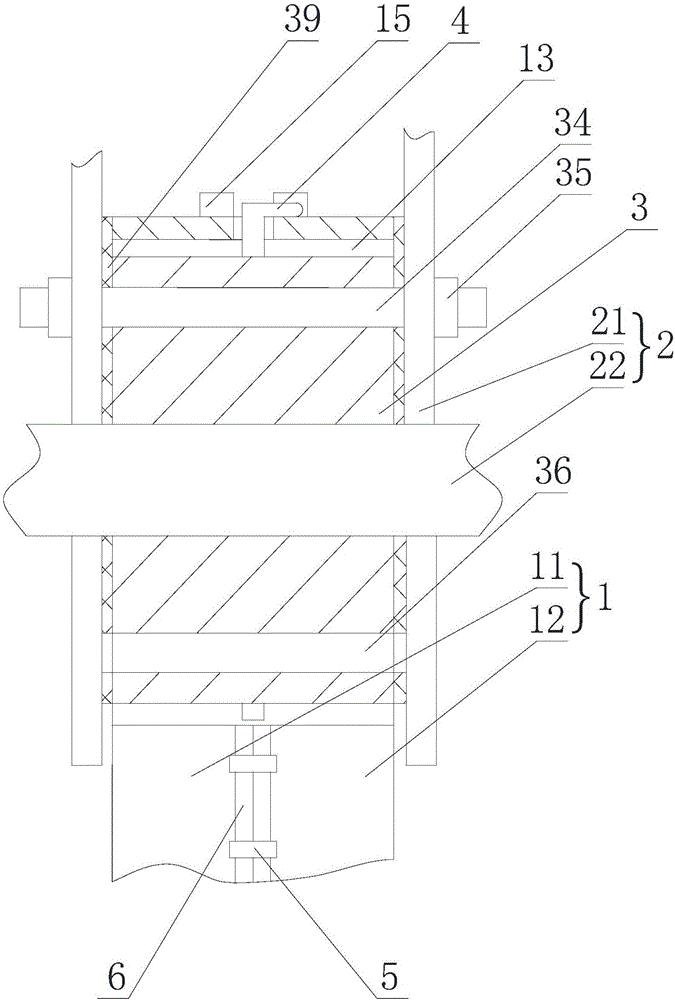

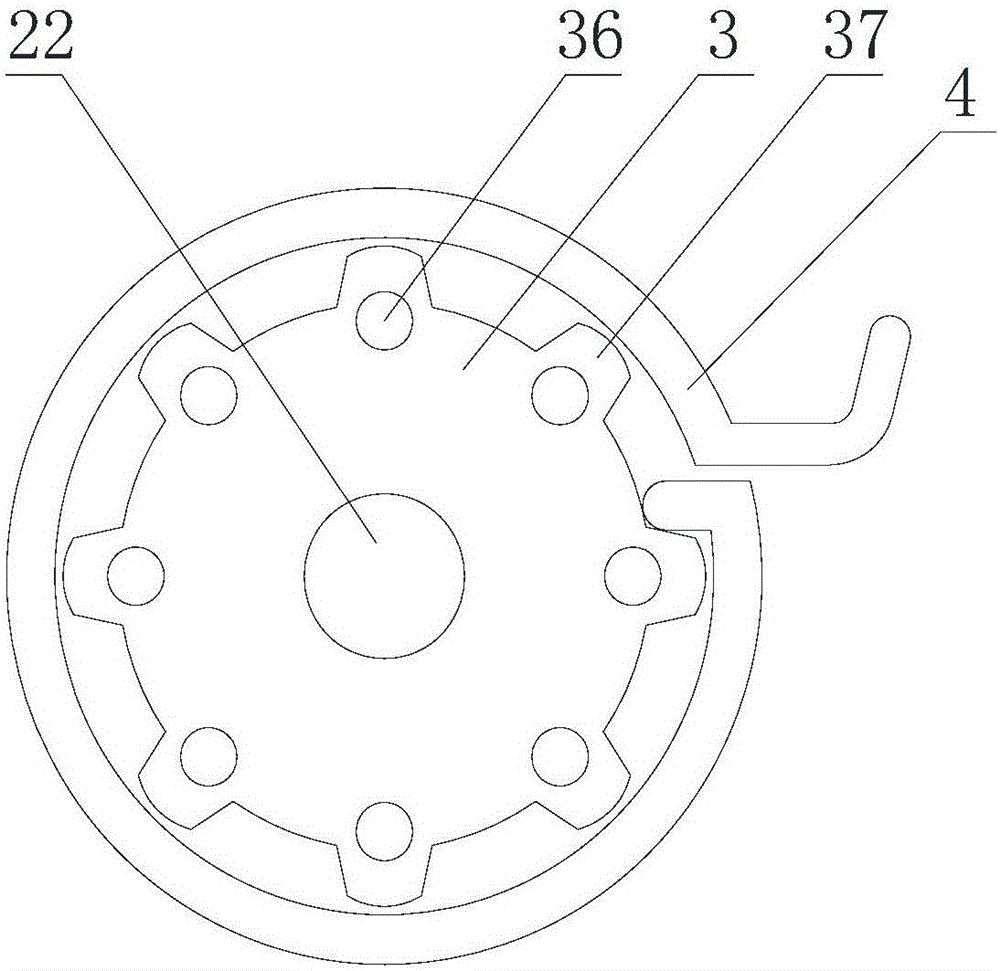

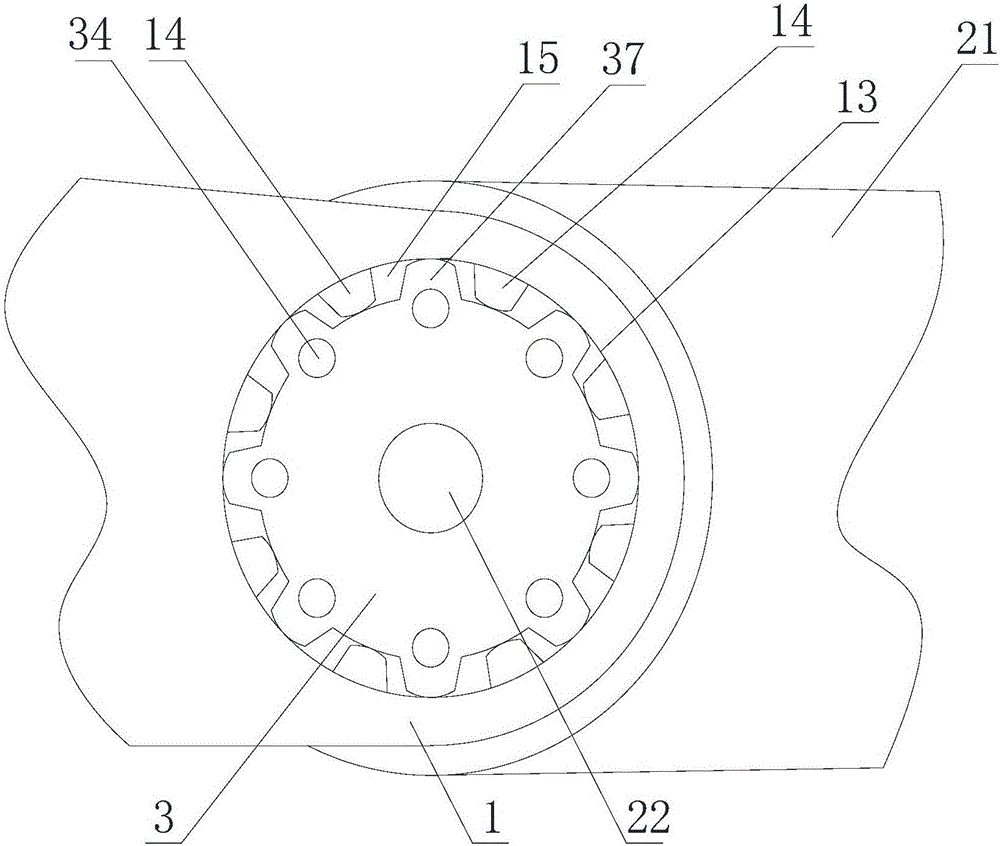

Elastic supporting piece of aerogenerator

InactiveCN101943135AReduce direct frictionReduce horizontal unilateral forceWind motor supports/mountsWind energy generationElastomerEngineering

The invention relates to an elastic supporting piece of an aerogenerator unit, in particular to an elastic supporting piece of an aerogenerator. The elastic supporting piece of the aerogenerator comprises an upper hood, a lower hood and an elastomer clamped between the upper hood and the lower hood, central holes of the upper hood and the lower hood respectively penetrate through an upper mandrel and a lower mandrel which are connected through threads and press the upper hood and the lower hood, the upper mandrel is connected in match with the external thread at the lower segment of a lifting column through the internal thread in the center, the height position of the upper mandrel can be adjusted by the rotation of the lifting column, and an upper supporting plate capable of lifting along with the lifting column is mounted at the top of the lifting column. The elastic supporting piece of the aerogenerator unit can ensure that the position of the generator mounted on the upper supporting plate is finely adjusted by adjusting the vertical position and the horizontal position of the upper supporting plate, is convenient to adjust, saves labor, has high accuracy, not only can lessen the direct friction of a metal piece by arranging wearing plates at the inner side and the outer side, but also can lessen the horizontal single-side force of the elastomer so as to prolong the service life of a member.

Owner:JIANGSU TIEKE NEW MATERIAL CO LTD

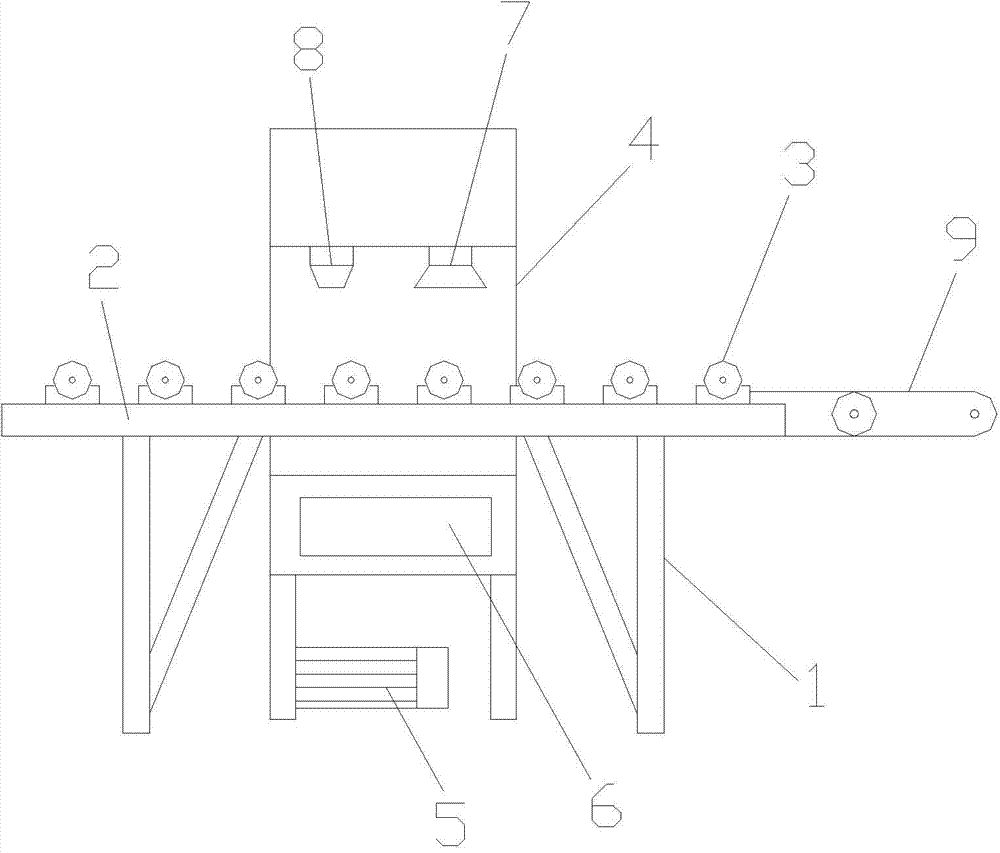

Automatic cleaning device

InactiveCN103586243AReduce direct frictionAvoid damageFlexible article cleaningCleaning using gasesChinese charactersBiochemical engineering

The invention relates to the technical field of glass processing production and discloses an automatic cleaning device. The automatic cleaning device is characterized by comprising a supporting frame, a fixing plate is arranged on the supporting frame, guide wheels are mounted on the fixing plate, a cleaning cabinet is arranged on one side of the supporting frame, a motor is arranged below the cleaning cabinet, an air blower is connected on the motor, an air outlet is arranged above the cleaning cabinet, a water spraying port is arranged on one side of the air outlet, a water supply pipe is connected on the water spraying port, a conveying device is arranged on one side of the fixing plate, and the cleaning cabinet is of a structure in the shape of a Chinese character 'ao'. The automatic cleaning device is reasonable in structure, simple to mount, convenient to use and good in using effect.

Owner:易兵

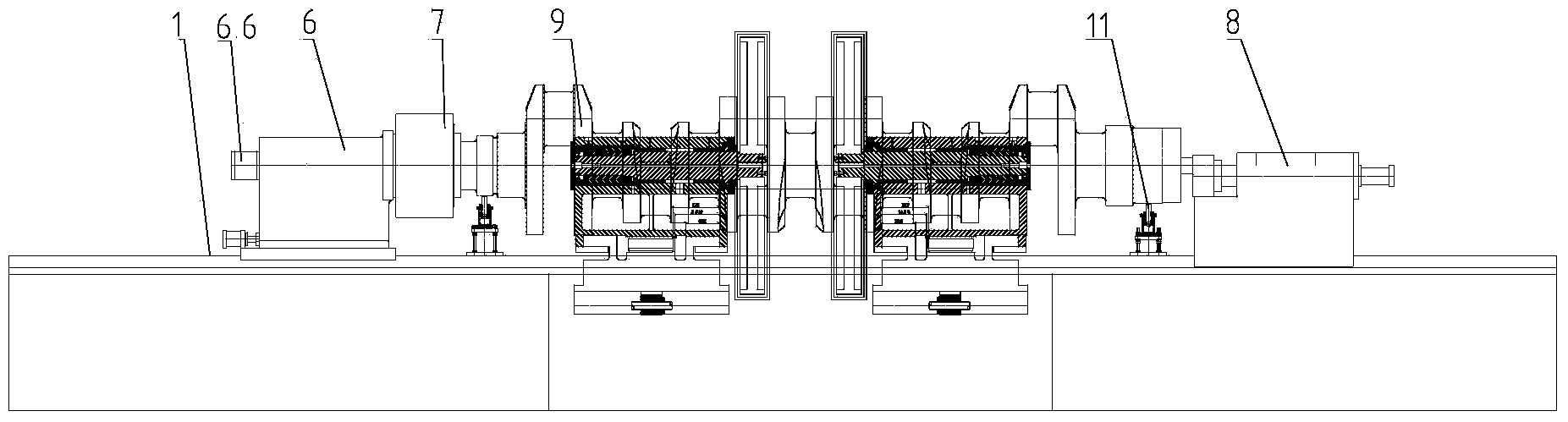

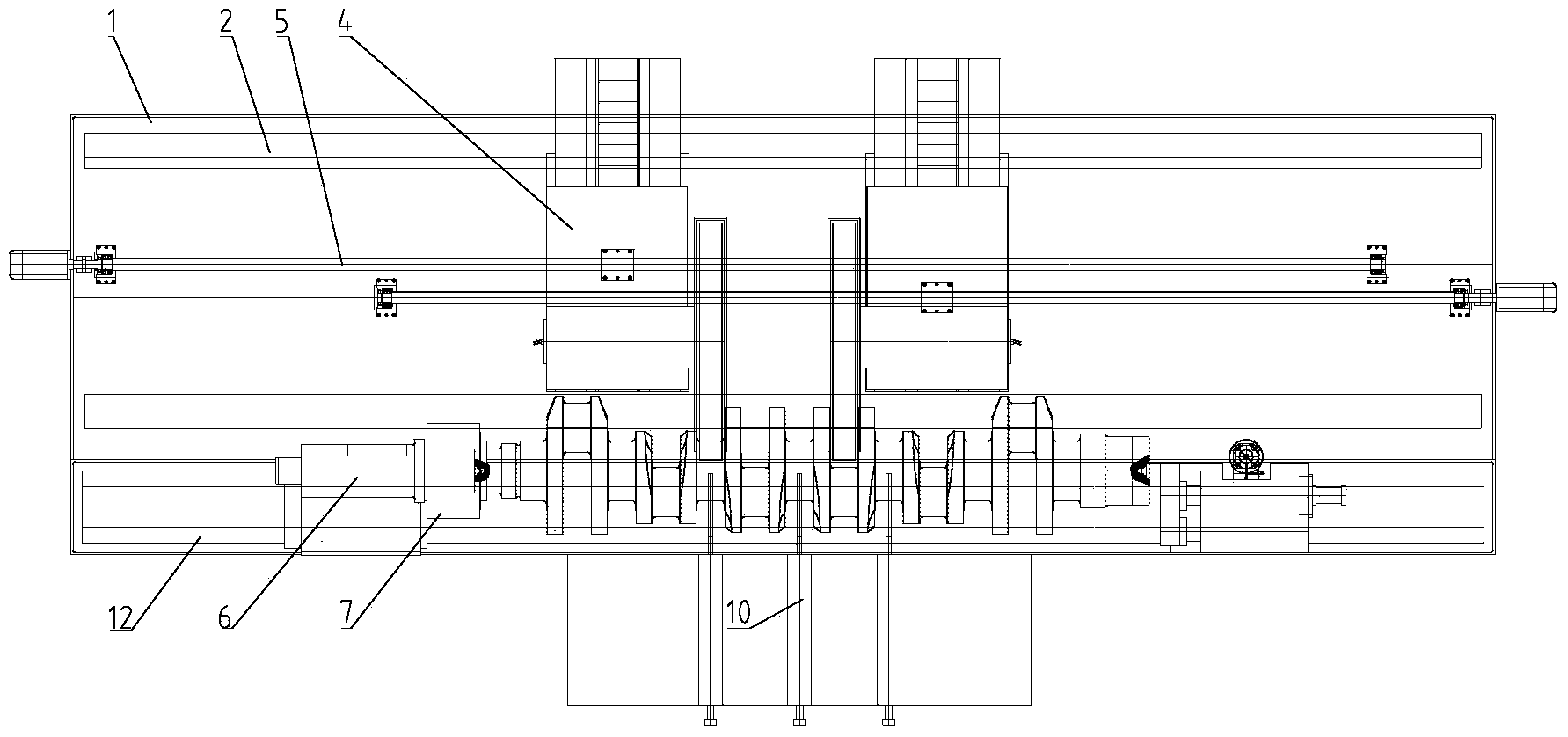

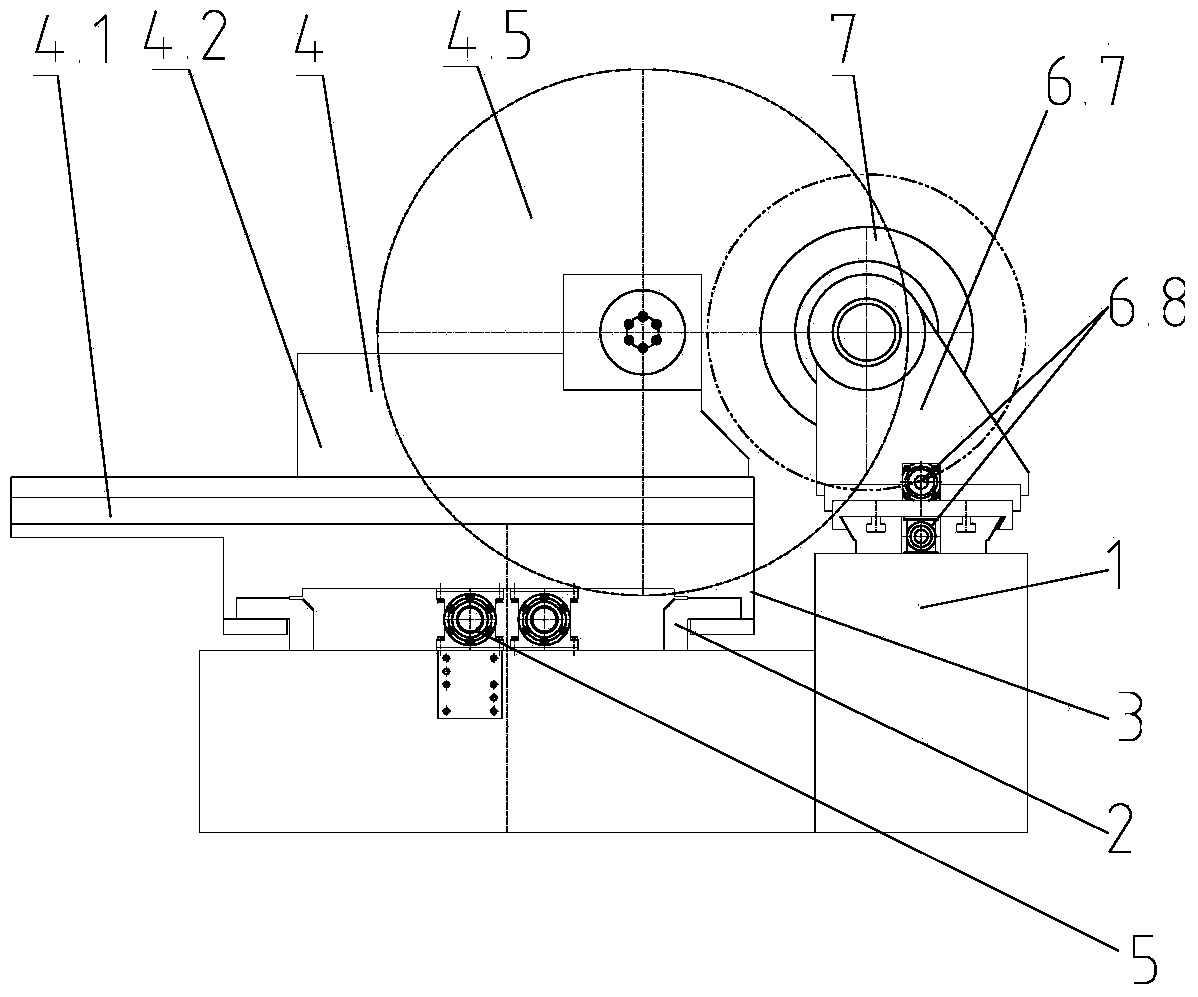

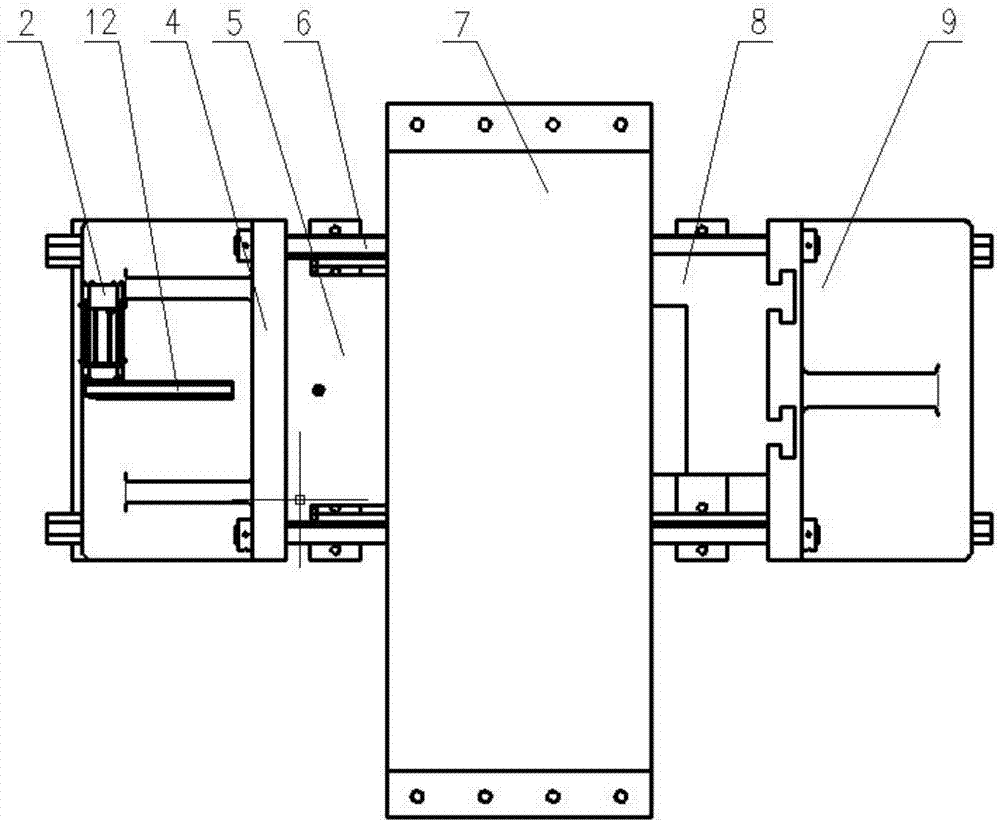

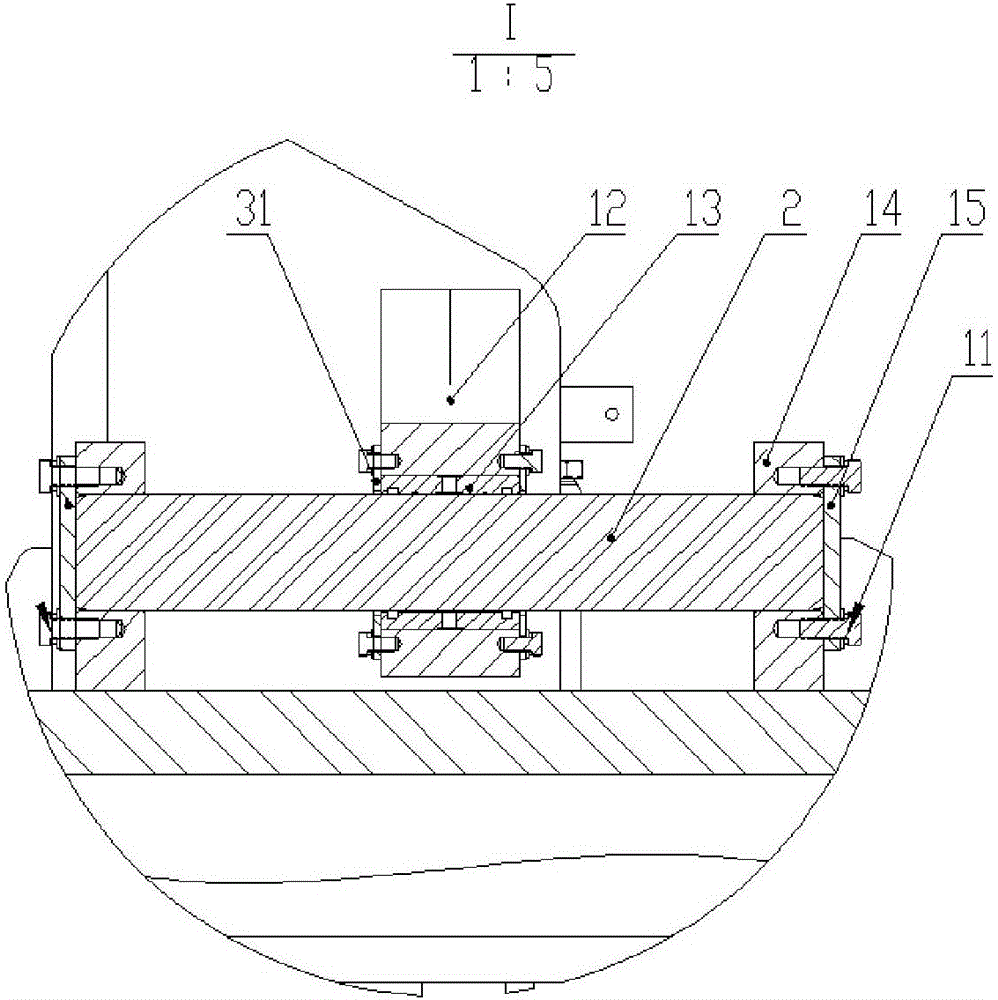

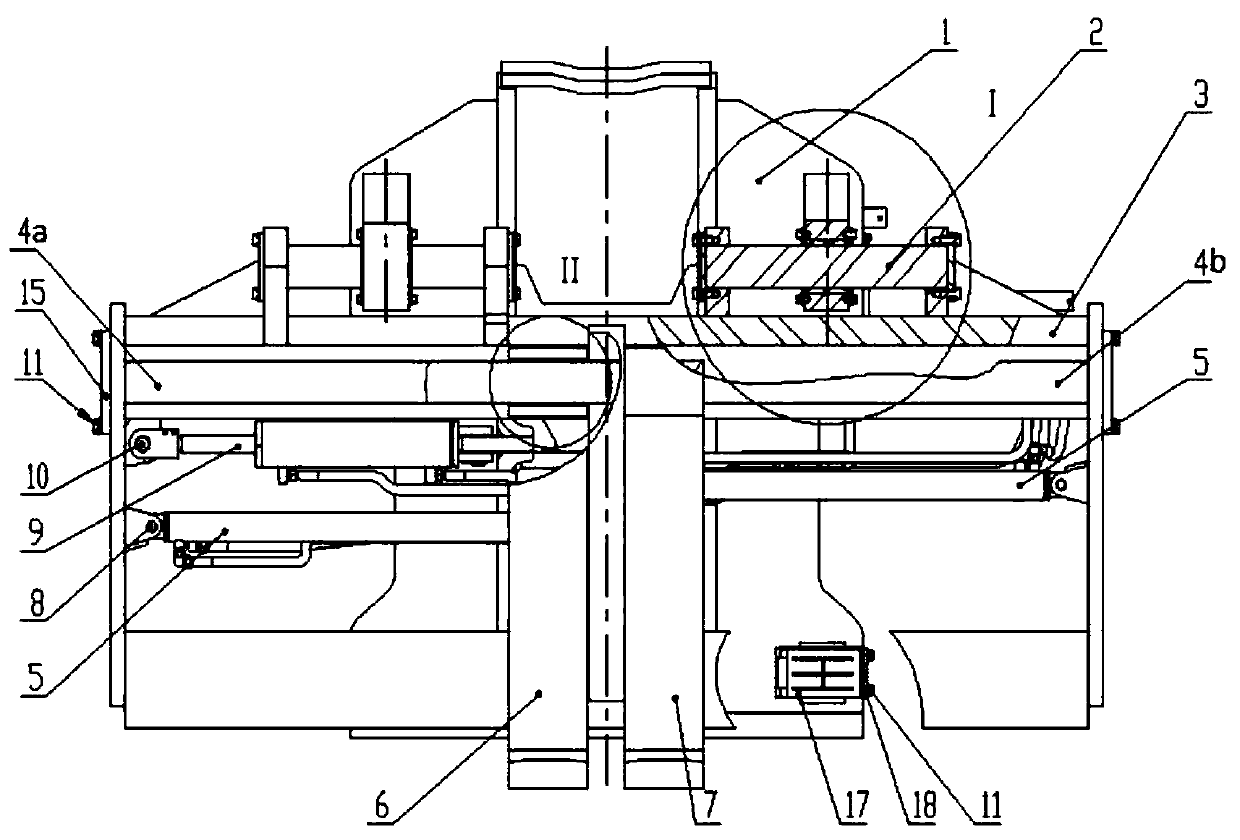

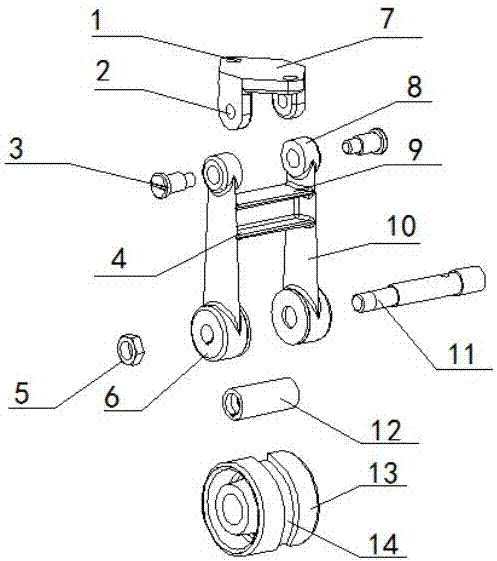

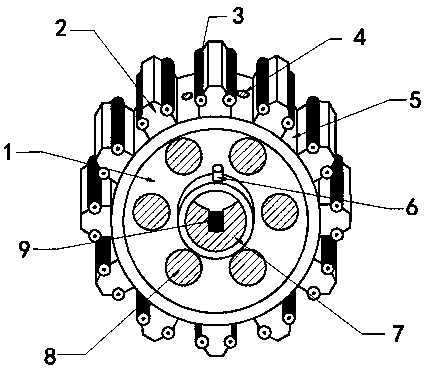

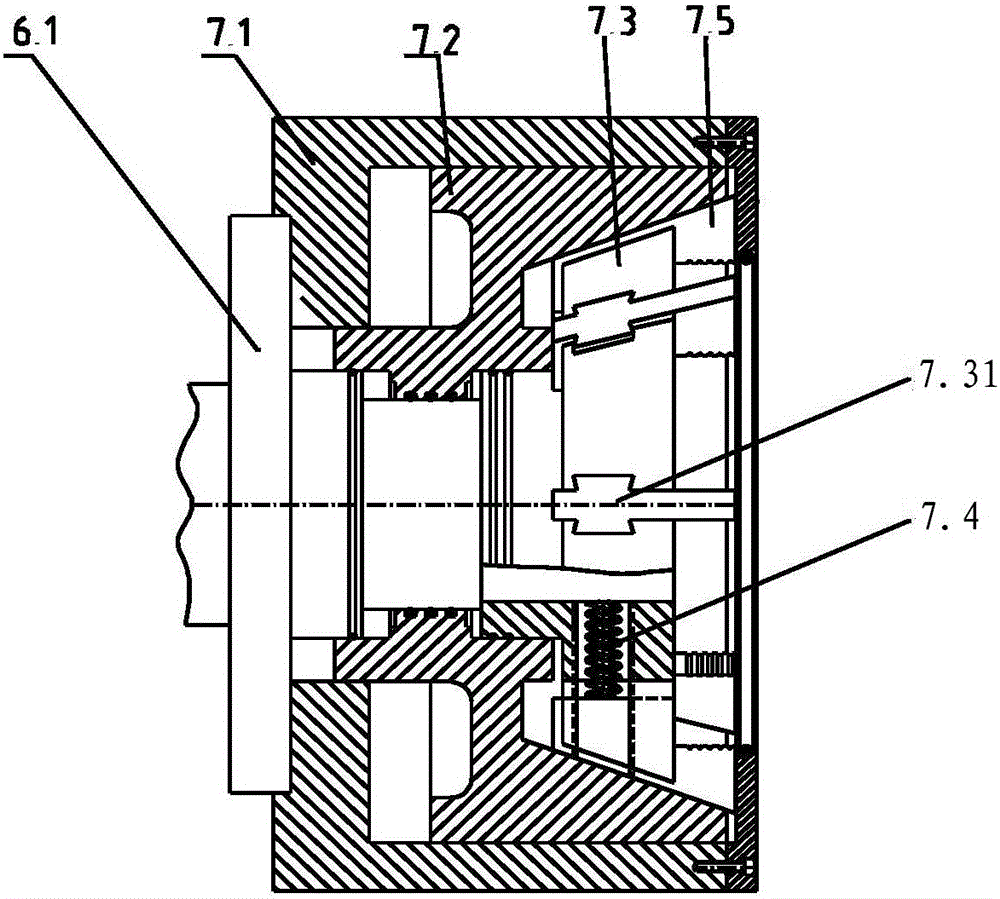

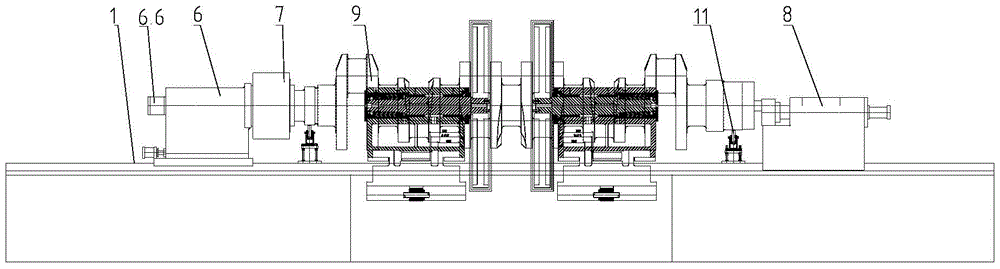

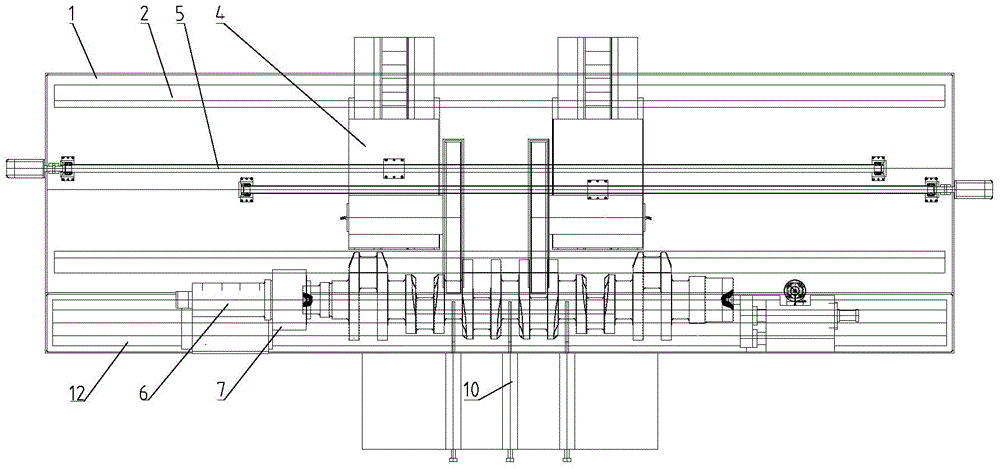

Numerically controlled large engine crankshaft grinder

ActiveCN104044024AReduce direct frictionHigh precisionRevolution surface grinding machinesGrinding drivesEngineeringDistributor

The invention relates to a numerically controlled large engine crankshaft grinder, which comprises a main bed, an axial grinding machine movement track is arranged on the main bed, an axial moving carriage is slidably connected with the axial grinding machine movement track, and a grinding machine assembly is slidably connected with the axial moving carriage; a main track is arranged on the main bed, a spindle head mechanism and a spindle tail mechanism are slidably connected with the main track, a first driver is connected with the bottom of the spindle head mechanism, the spindle head mechanism comprises a spindle box and a spindle mounted in the spindle box, a fixture mechanism is fixed on the front end of the spindle, an oil distributor is fixed on the rear end of the spindle, a motor rotor and a motor stator which cooperate with each other and are arranged in the spindle box are sleeved on the spindle, and the center of the front end of the spindle is provided with a centre. The numerically controlled large engine crankshaft grinder increases production efficiency, and provides a reliable guarantee for product quality.

Owner:湖北伟翔数控机床股份有限公司

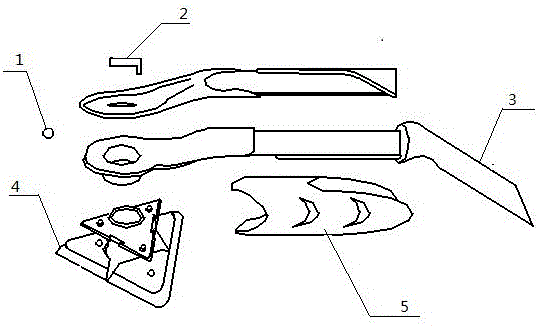

Rotatable seam beautifying tool

InactiveCN105696779AReduce direct frictionImprove comfortBuilding constructionsEngineeringMechanical engineering

The invention discloses a rotatable beautifying tool, which is composed of a lamp, a glass, a switch, a scraper, a triangular scraper, and an encapsulation. The surface and the triangular scraping head are at the front, and the glue is in the middle. The lamp and the glass are on the front and upper side, and it is more convenient to work by turning on the lamp when in use, especially at night or in a dark working place. The switch is located at the top, and is made of ABS injection molding and is silver-white, and the lighting is controlled by controlling the opening and closing of the switch. The scraper is at the rear end, and is sprayed with lime green by ABSA injection molding, and the scale is marked on the scraper, which can accurately control the width of the gap. The triangular scraping head is at the front, and three rotatable and adjustable beauty seam heads are designed, which can quickly perform beauty seam treatment on gaps of different sizes. The encapsulation is in the middle, and it is black by injection molding of PA. The encapsulation can reduce the direct friction between the hand and the tool and increase the comfort.

Owner:陈丽晓

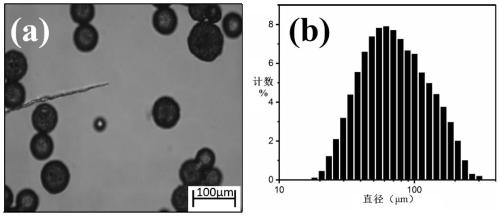

Preparation method of self-lubricating microcapsule/MC nylon composite material

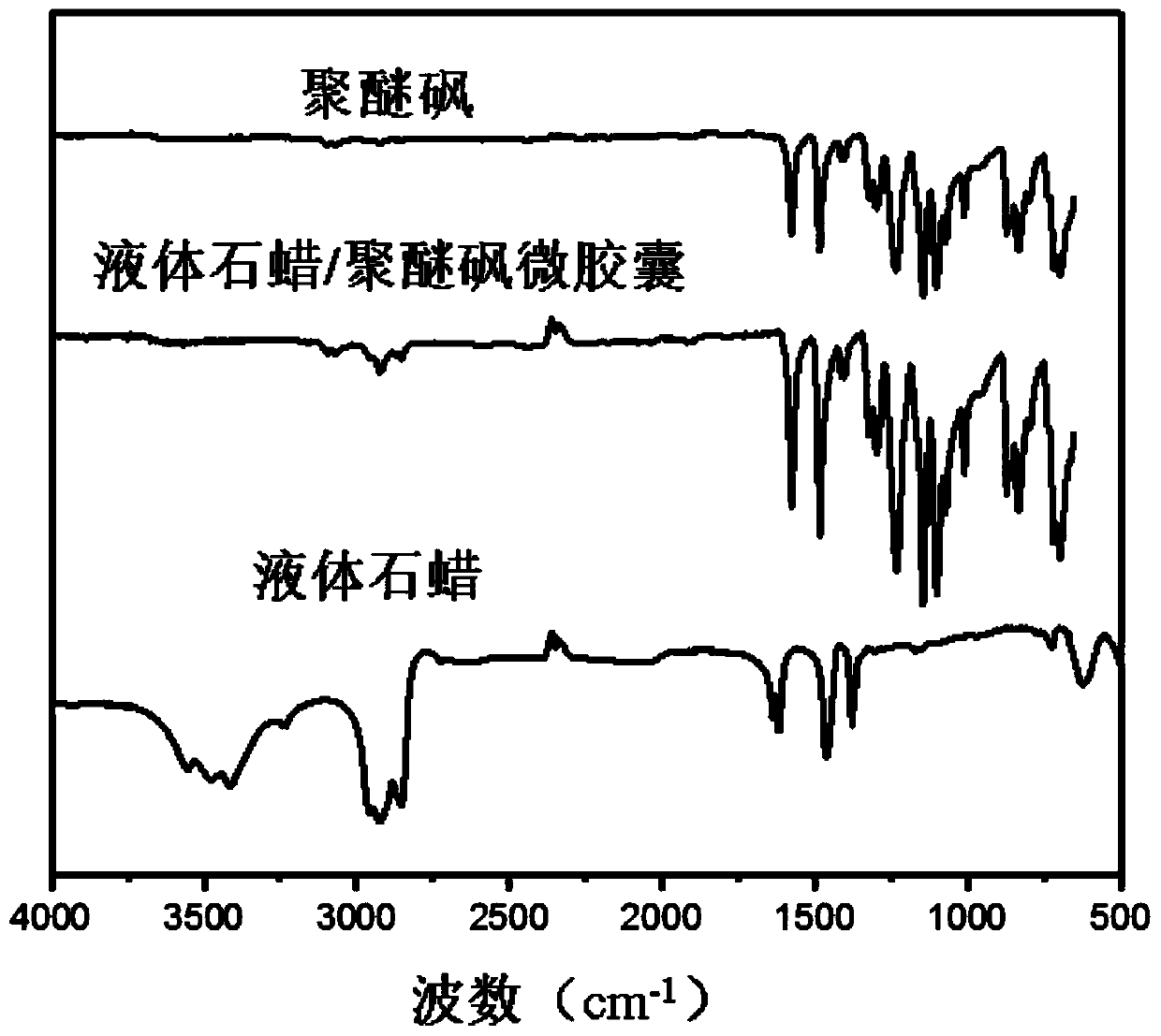

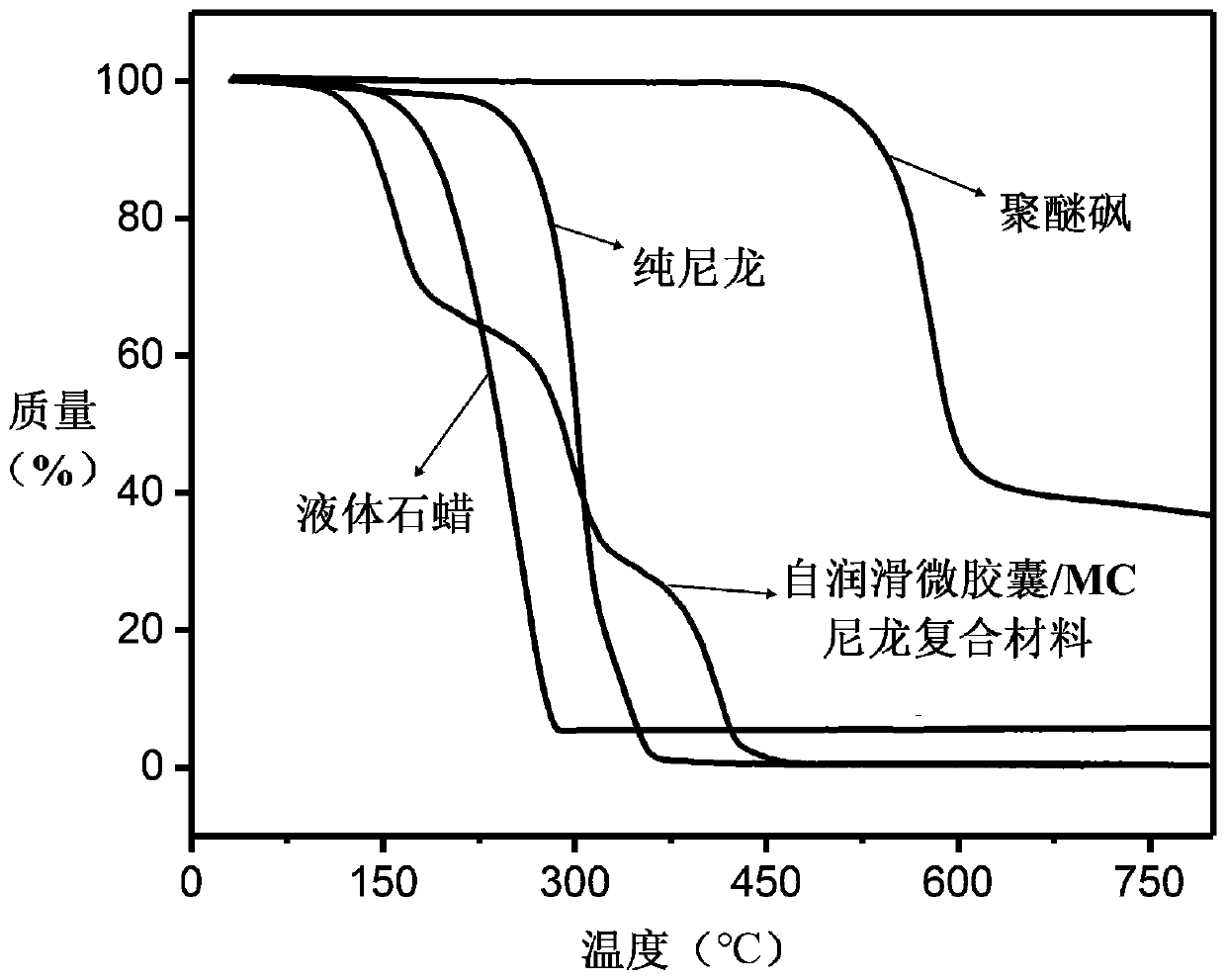

InactiveCN111040431AOvercoming Microphase Separation PhenomenaGuaranteed mechanical propertiesMicroballoon preparationLubricant compositionPolymer scienceCaprolactam

The invention discloses a preparation method of a self-lubricating microcapsule / MC nylon composite material. The preparation method comprises the following steps: 1, preparing a microcapsule shell layer precursor, 2, preparing a microcapsule core layer precursor, 3, adding the microcapsule core layer precursor into the microcapsule shell layer precursor, carrying out mixing, cleaning and drying toobtain a liquid paraffin / polyethersulfone microcapsule, 4, heating caprolactam CL to be completely molten, and then adding the liquid paraffin / polyethersulfone microcapsules obtained in the step 3 into the melt, 5, adding a catalyst and an activating agent into the melt, and carrying out stirring to obtain a to-be-polymerized system of MC nylon monomers and microcapsules, and 6, pouring the to-be-polymerized system obtained in the step 5 into a mold, carrying out heat preservation for t3, and cooling and demolding after the reaction and curing are completed, so as to obtain the required self-lubricating microcapsule / MC nylon composite material. The oil-containing microcapsule prepared by the invention is used as a filler and is added into MC nylon prepared by anionic ring-opening polymerization, so that the self-lubricating property of the MC nylon is improved, and the wear rate is reduced.

Owner:SICHUAN UNIV

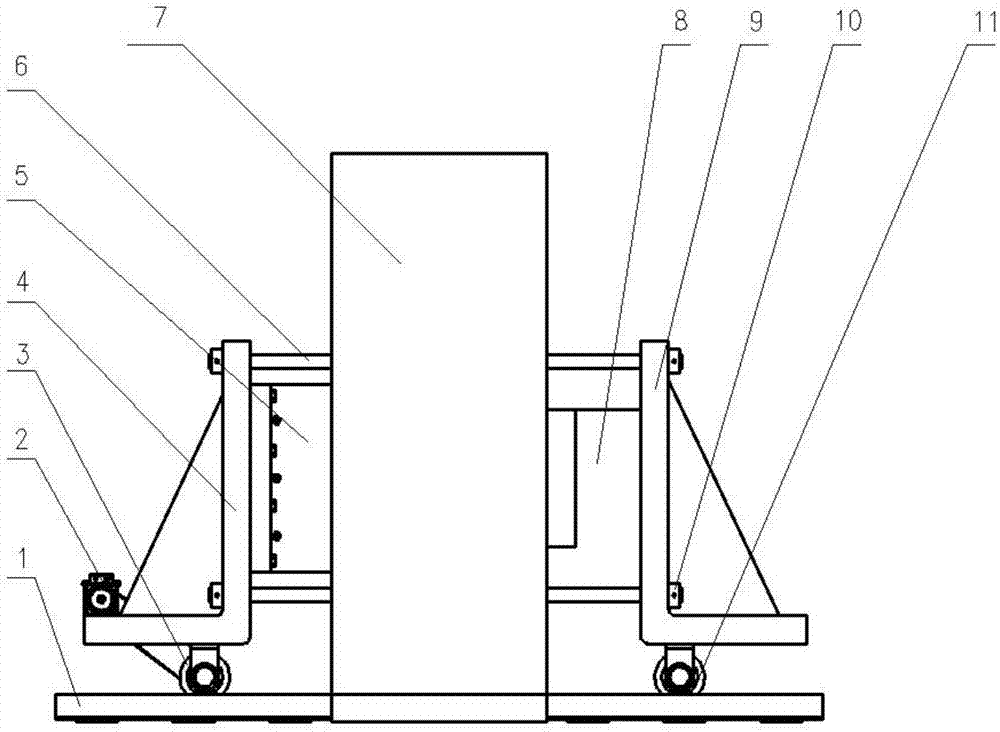

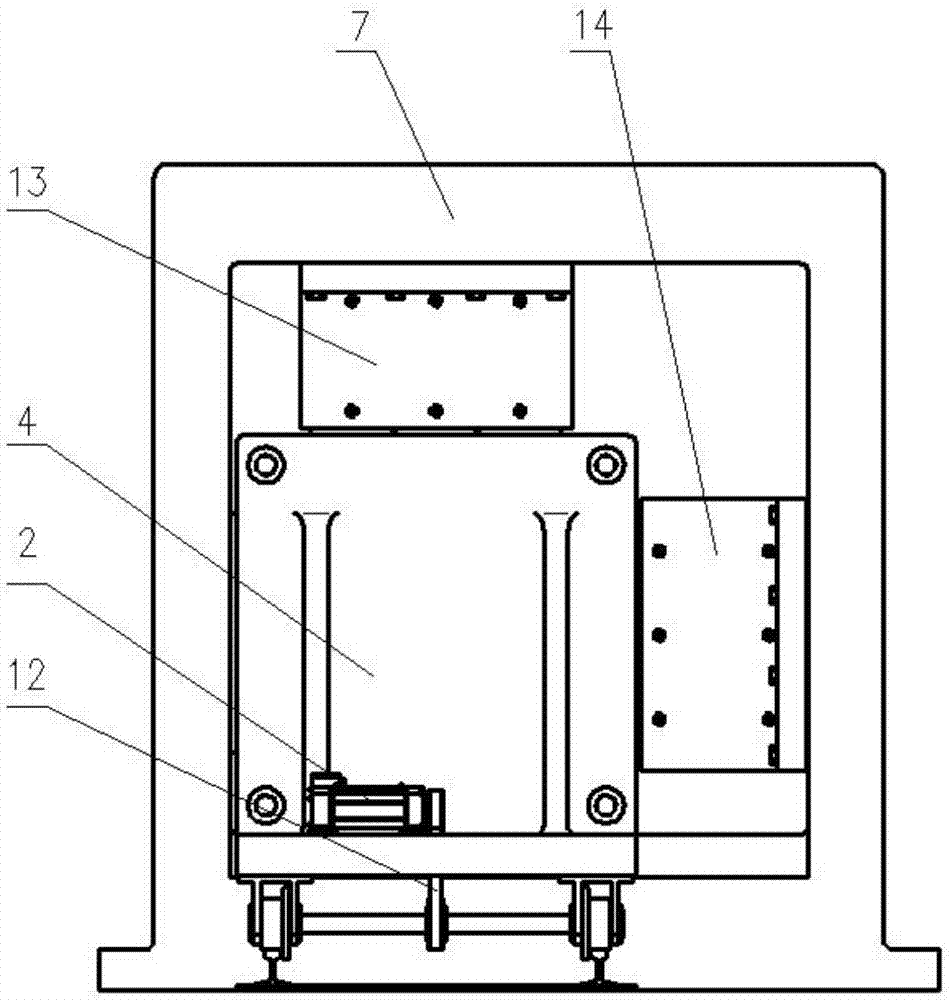

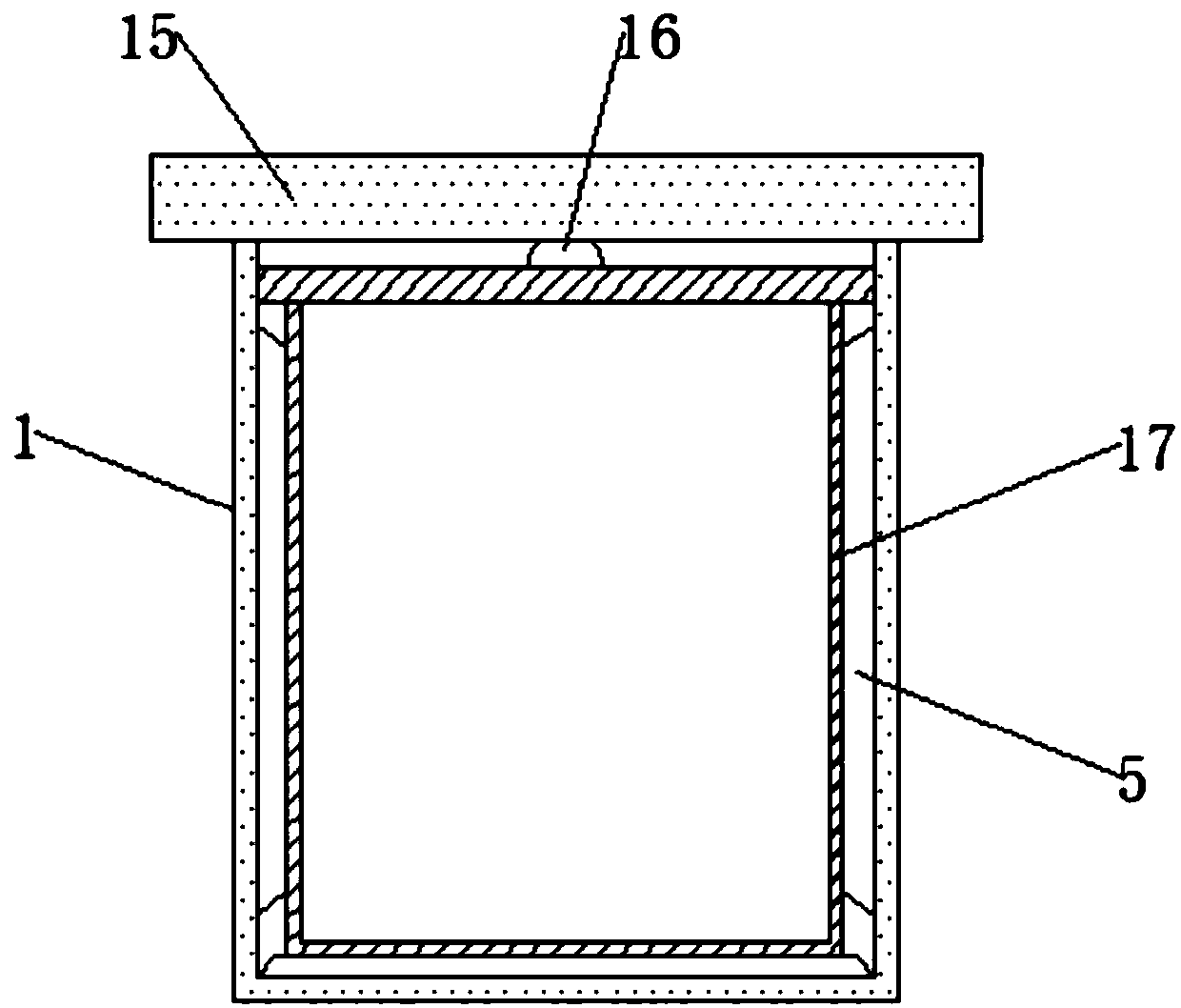

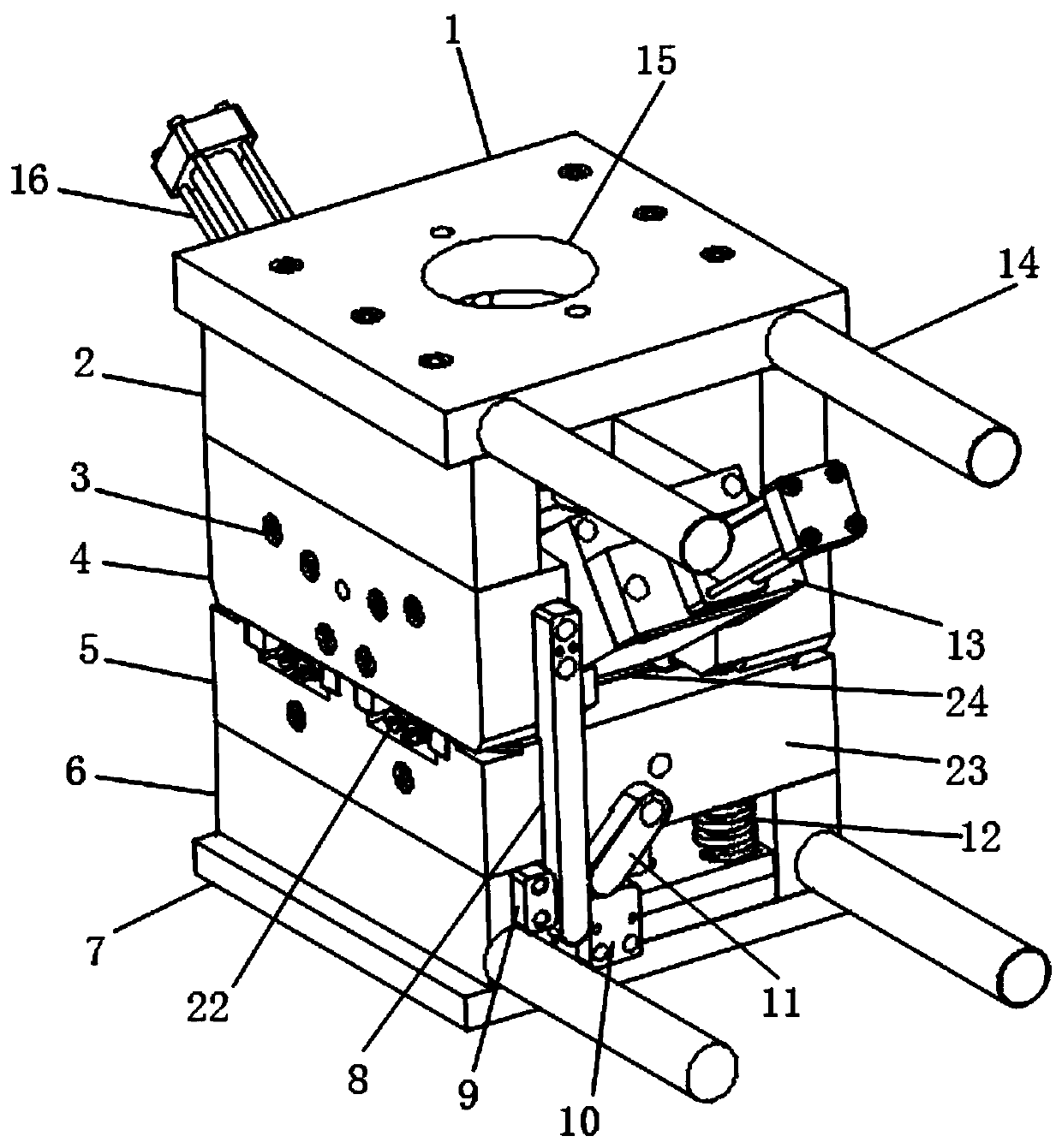

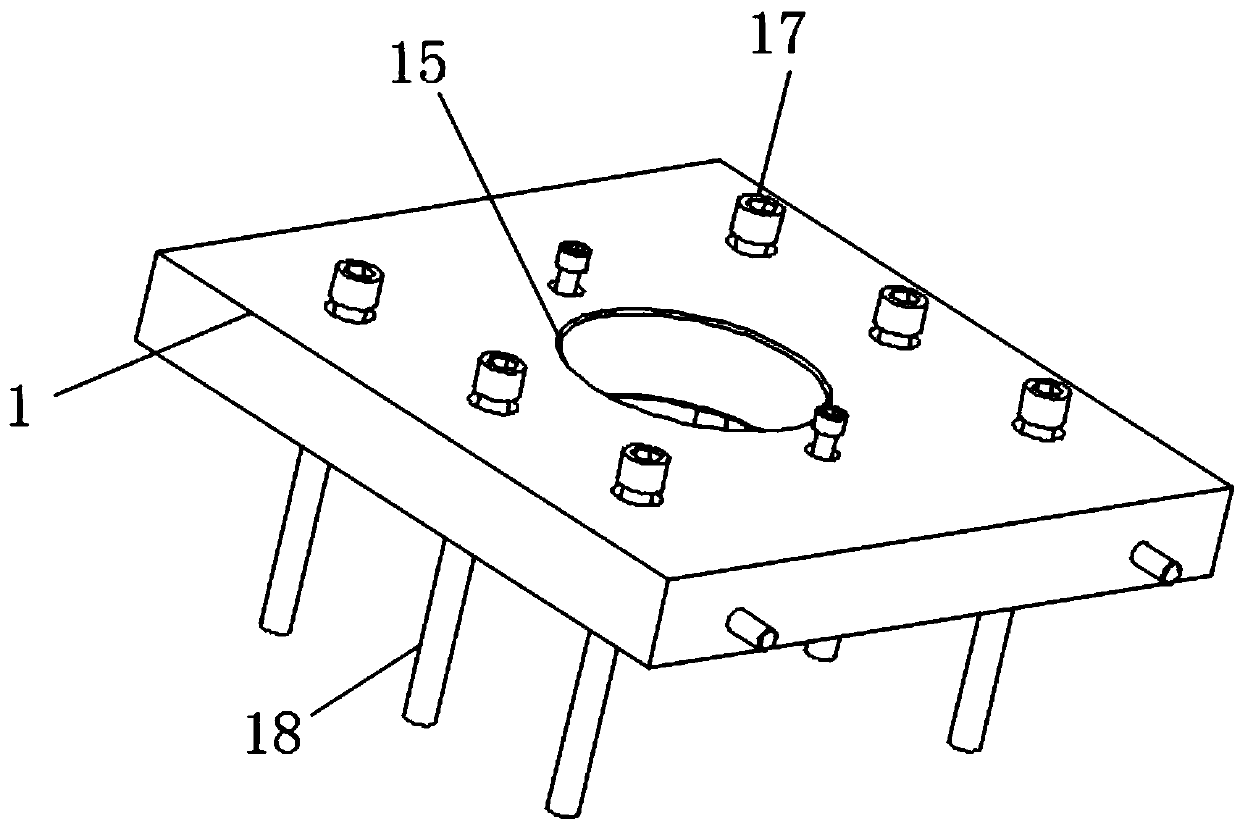

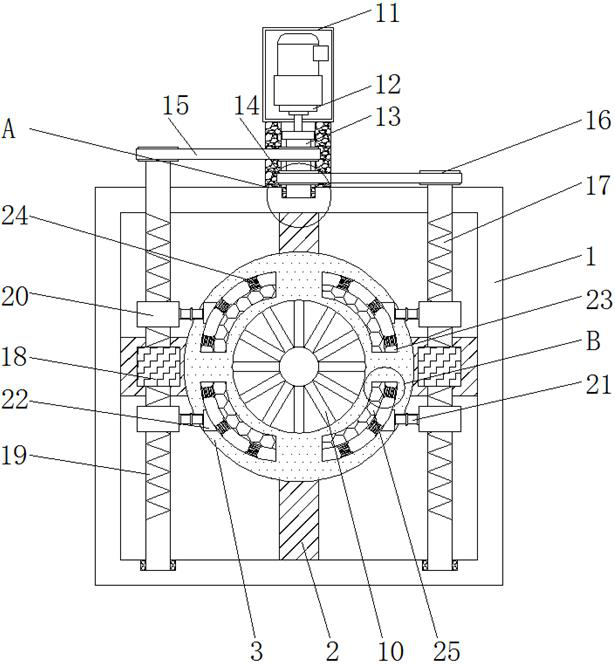

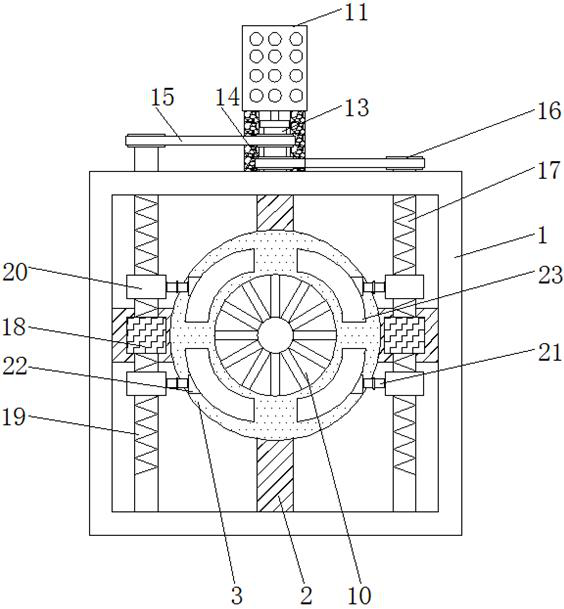

Experimental apparatus capable of automatically loading full section of rock

ActiveCN107314939AReduce direct frictionHigh precisionMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesHydraulic cylinderTransmission belt

The invention provides an experimental apparatus capable of automatically loading the full section of rock. The objective of the invention is to design an experimental apparatus capable of carrying out automatic three-direction static-dynamic coupled loading on rock. The experimental apparatus comprises a fixed outer frame, a lateral hydraulic cylinder group, a top hydraulic cylinder group, a transverse hydraulic cylinder group, a material loading track, a frame-type material loading structure and a self-adaptive elastic roller structure, wherein the lateral hydraulic cylinder group and the top hydraulic cylinder group are fixed on the fixed outer frame; the frame-type material loading structure comprises a motor, a motor fixing plate, a driven fixing plate, a material discharging plate, a connecting rod, a synchronous transmission belt and wheels. According to the invention, the apparatus provides large-tonnage static-dynamic coupled load via the hydraulic cylinder groups so as to realize loading on square rock; the self-adaptive elastic roller structure and frame-type material loading structure enables material loading to be more convenient; the control parts of the apparatus are operated by operators on a host computer, so automation is realized; so the apparatus is a convenient, stable and efficient automatic loading device for rock simulation experiments.

Owner:HARBIN ENG UNIV

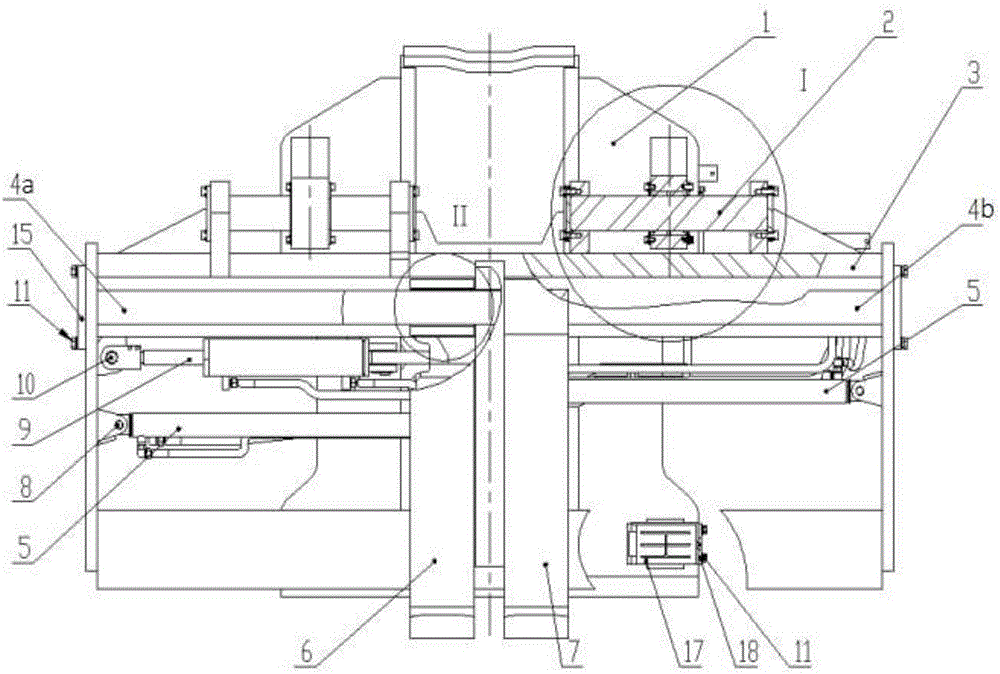

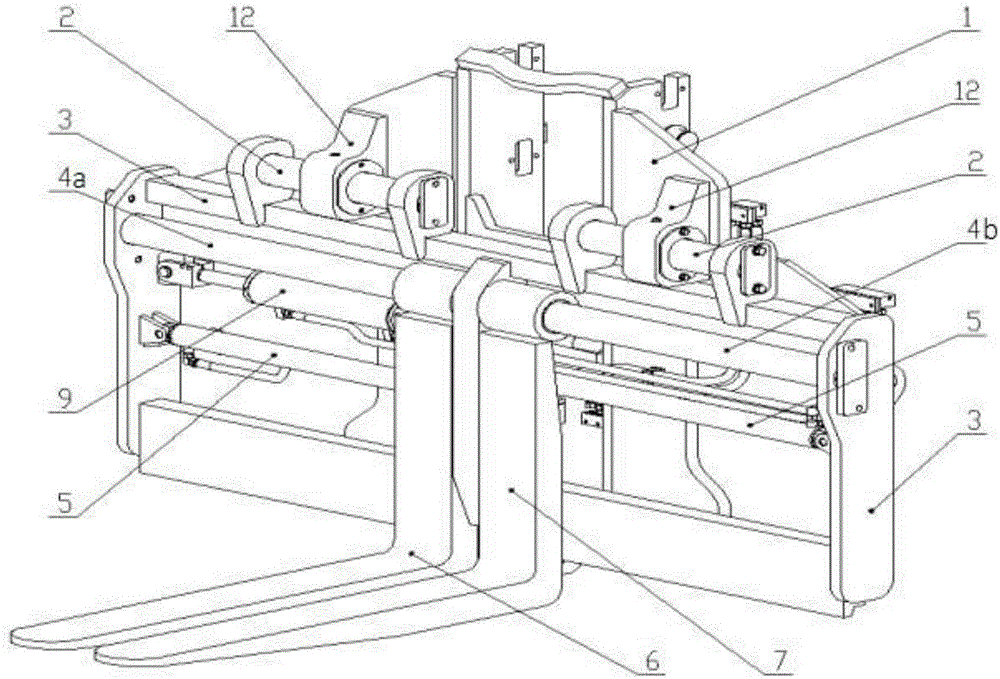

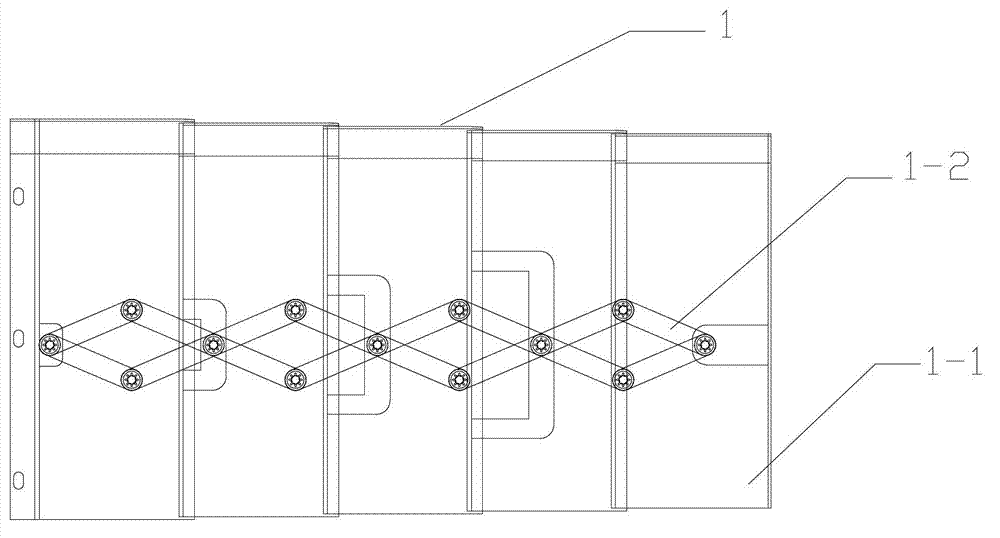

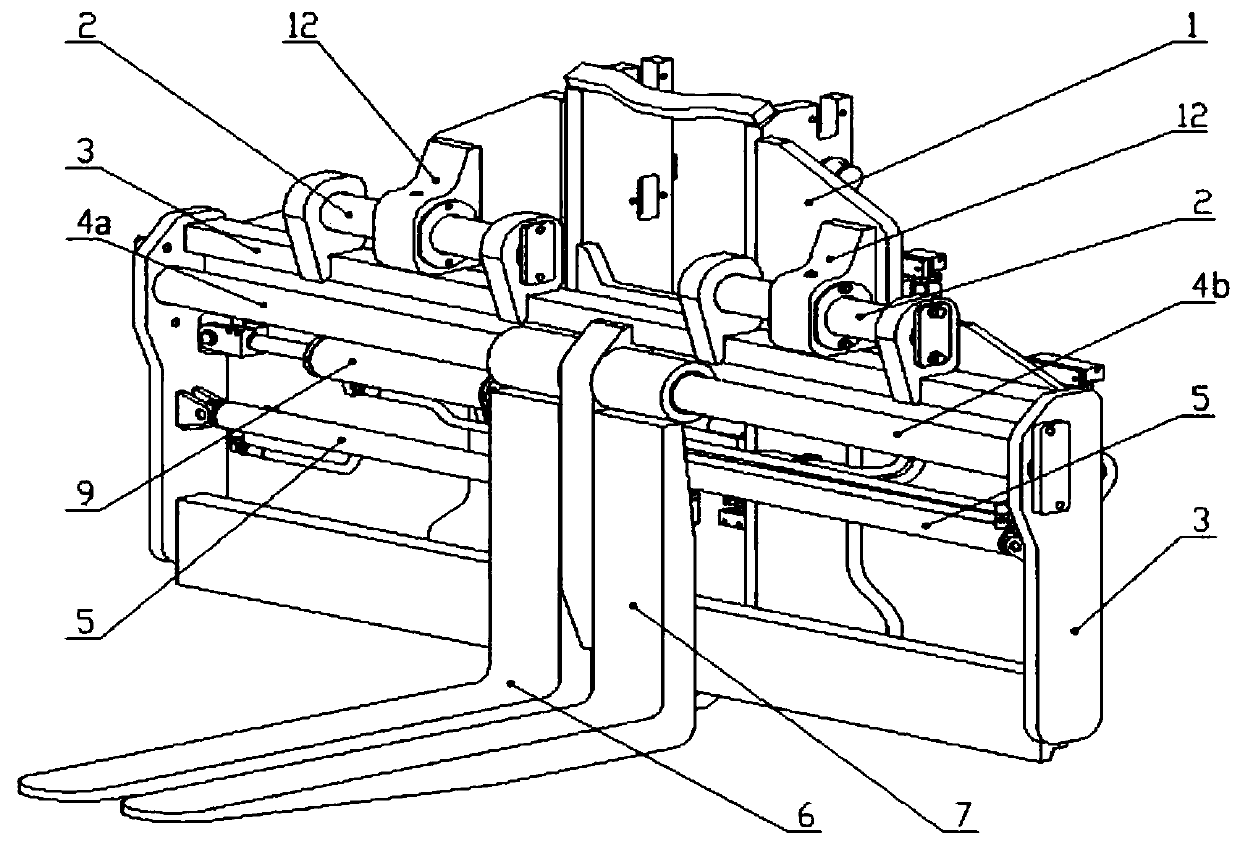

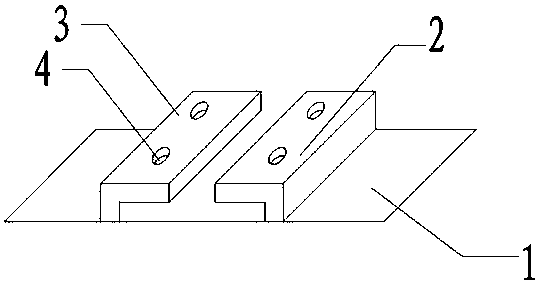

Wide-field-of-view sidesway fork positioner

The invention relates to the field of forklifts, in particular to a wide-field-of-view sidesway fork positioner. The wide-field-of-view sidesway fork positioner comprises a front pallet fork carrier, a rear pallet fork carrier, a left pallet fork and a right pallet fork. The rear pallet fork carrier comprises two opposite vertical column plates. The portion between the two vertical column plates is sequentially connected with an upper cross beam, a middle cross beam, a stopper chain plate and a lower cross beam from top to bottom. Two side plates are symmetrically arranged on the opposite sides of the two vertical column plates. Two shaft brackets are symmetrically arranged on the upper portions of the two side plates. Two adjusting supports are symmetrically arranged on the lower portions of the two side plates. Adjusting gaskets are installed in the adjusting supports. A sidesway oil cylinder rear support is arranged at the position, between the corresponding shaft bracket and the corresponding adjusting support, of one side plate. By means of the wide-field-of-view sidesway fork positioner, the overall field of view for sidesway distance adjustment of a forklift can be widened, and operating safety is improved; the structures of the front pallet fork carrier and the rear pallet fork carrier are more reasonable, fewer weld joints are generated, the machining difficulty is lowered, and assembly and adjustment are simpler; and the maintenance cost is reduced, and market competitiveness is improved.

Owner:ANHUI HELI CO LTD

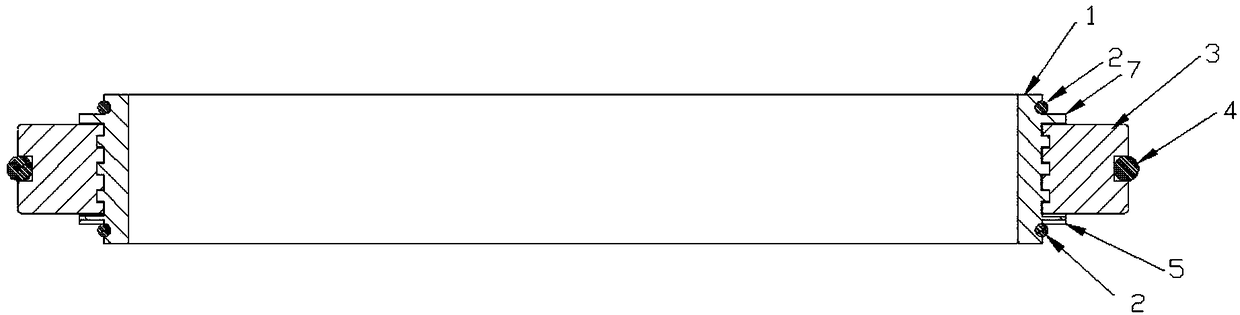

Shaft shield

InactiveCN102900760AReduce direct frictionSimple structureLinear bearingsBellowsStructural engineering

Owner:KUNSHAN ETEK METAL IND

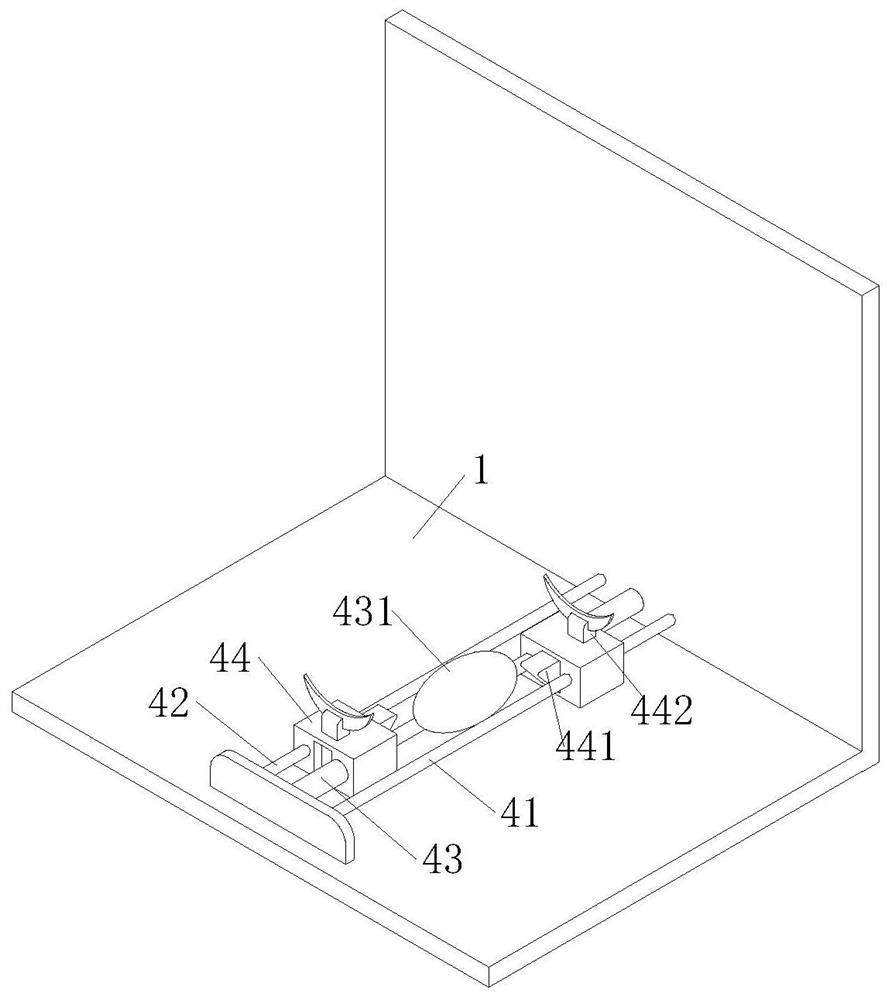

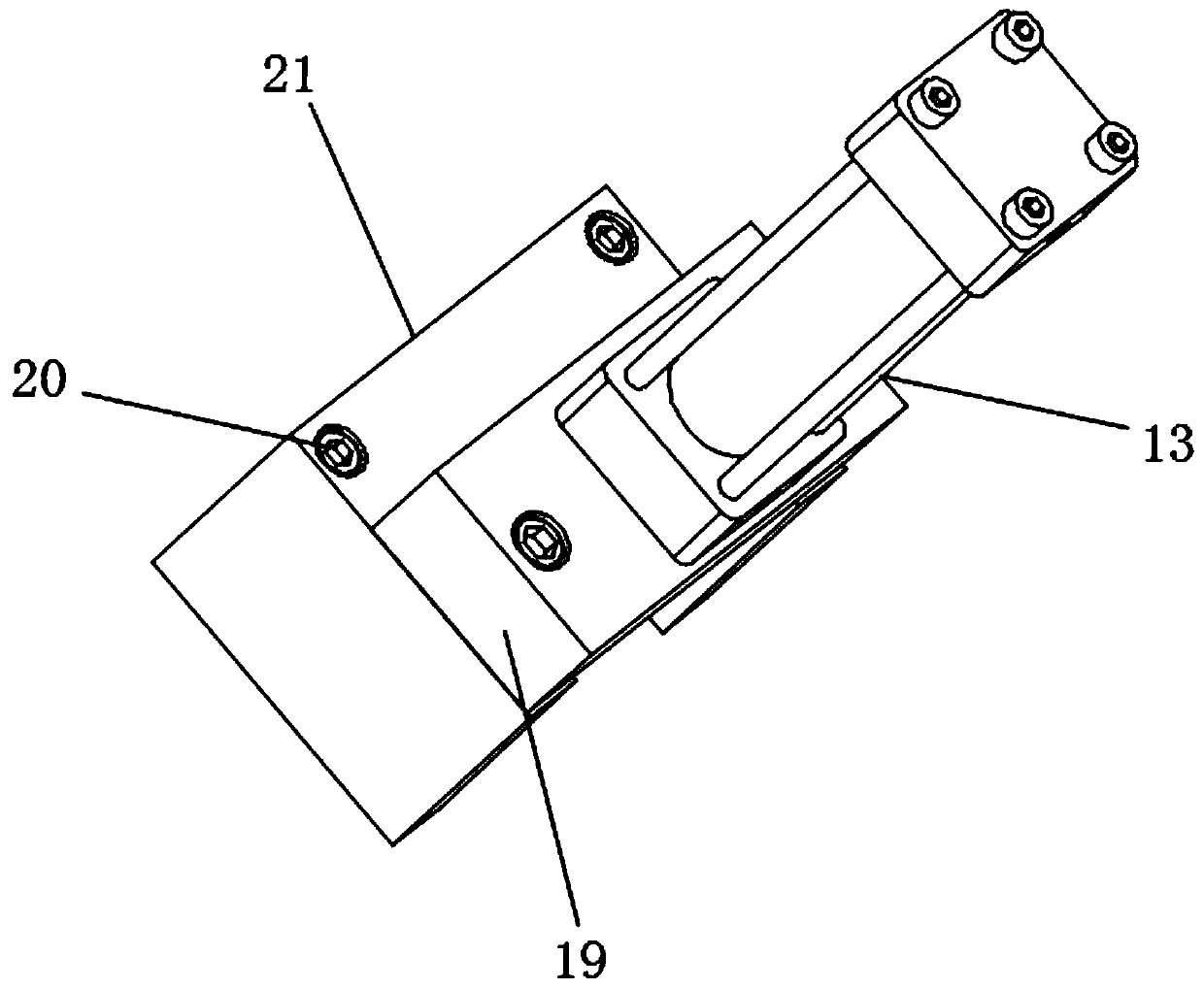

Miscellaneous thread end cleaning mechanism for silk thread winding of textile machine

ActiveCN113622066AAchieve the effect of wind dust removalConvenient for centralized collectionFibre cleaning/openingEngineeringTextile

The invention relates to the technical field of silk thread winding, in particular to a miscellaneous thread end cleaning mechanism for silk thread winding of a textile machine. The miscellaneous thread end cleaning mechanism comprises a supporting seat, and a separation structure is arranged on the top side of the supporting seat; a scraping structure is arranged on the inner side of the separation structure; a cleaning structure is arranged on the bottom side of the supporting seat; a penetrating structure is arranged on the side surface of the separation structure; a guide structure is arranged on the side face of the supporting seat; wind power scrap removal is carried out on passing silk threads through the separation structure, so that impurities such as part of thread ends attached to the silk threads are preliminarily separated, scraps firmly attached to the surfaces of the silk threads are further removed through the scraping structure, and therefore the scrap removal efficiency is improved; and the separated impurities are collected in a centralized mode through the cleaning structure, treatment is convenient, silk threads can conveniently penetrate through a sealing shell through the penetrating structure, conveying of the silk threads is guided through the guide structure, and direct friction between the silk threads and the device in the silk thread conveying process is reduced.

Owner:闻军

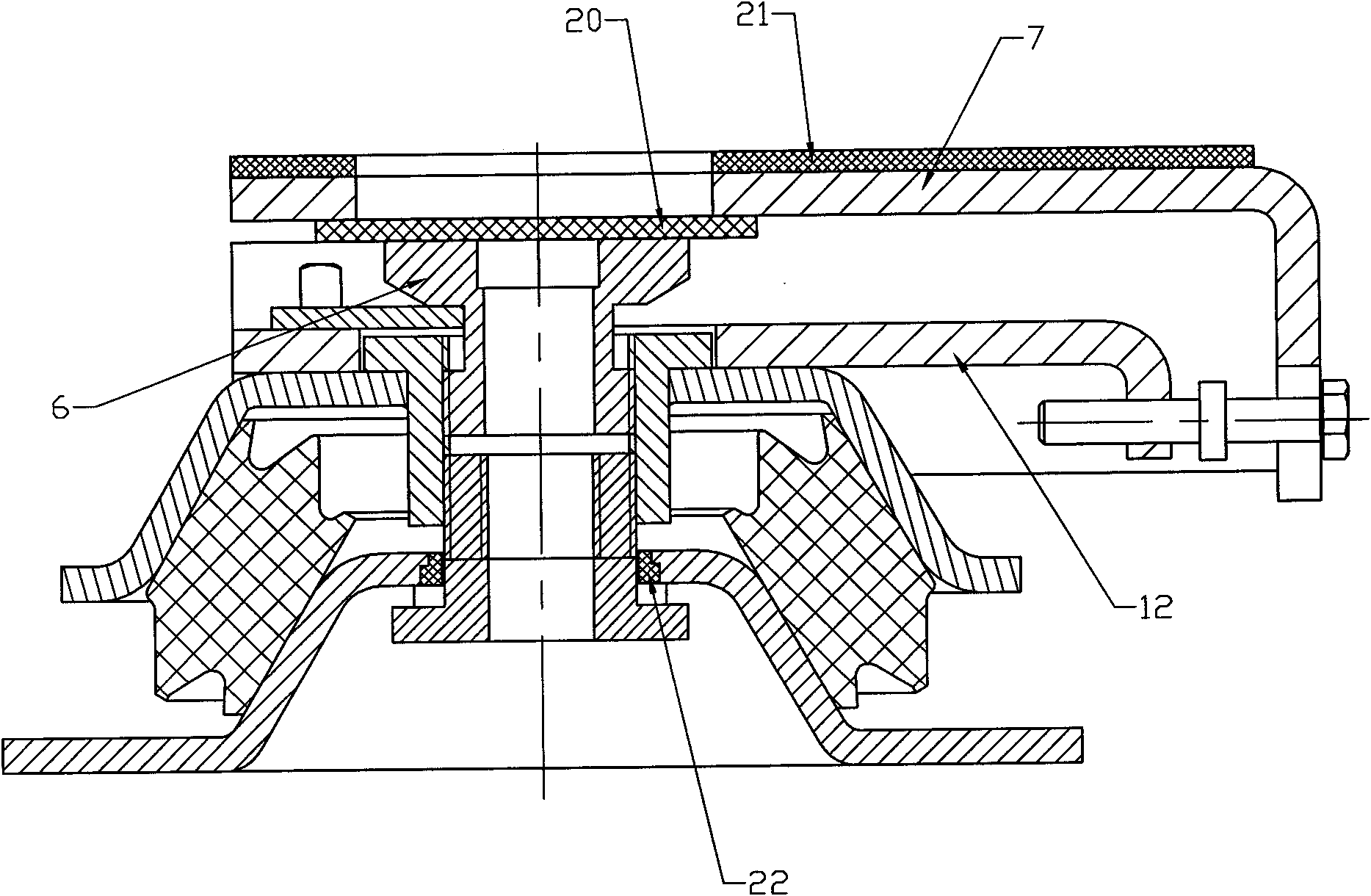

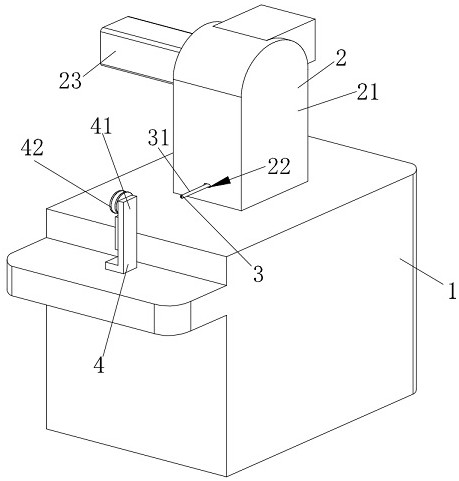

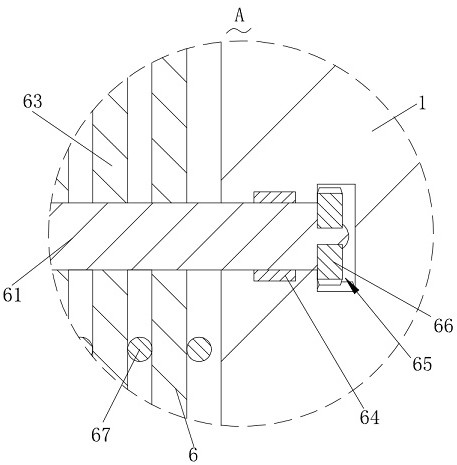

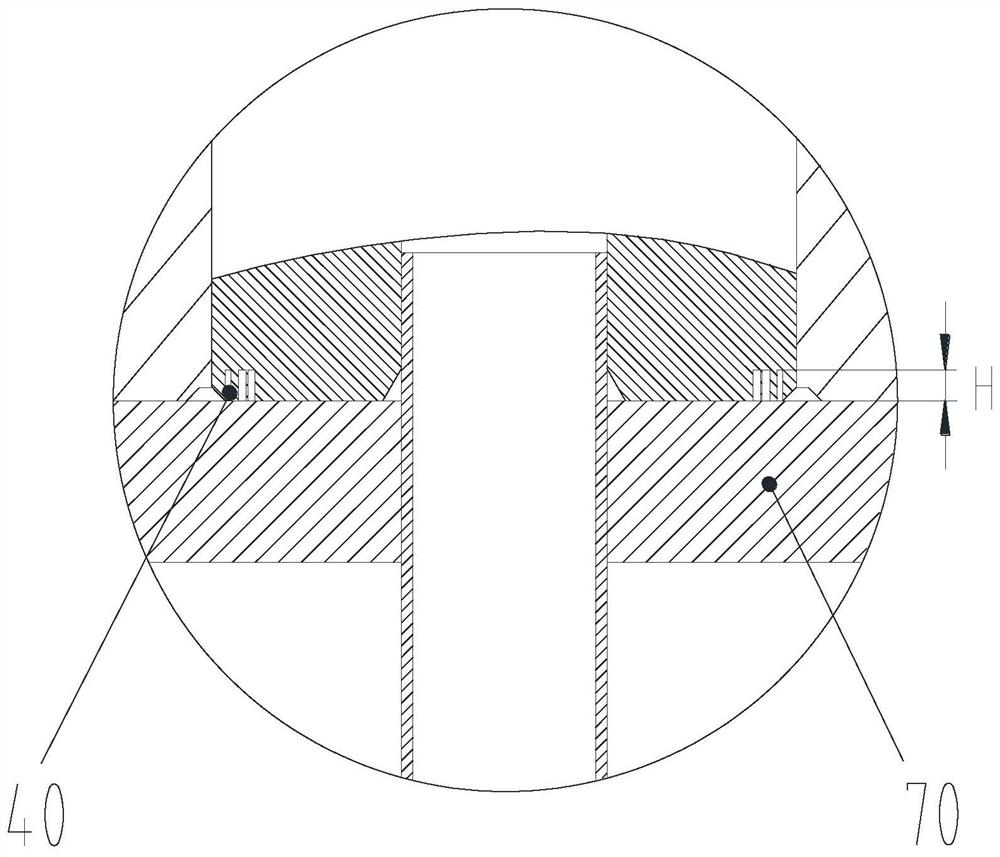

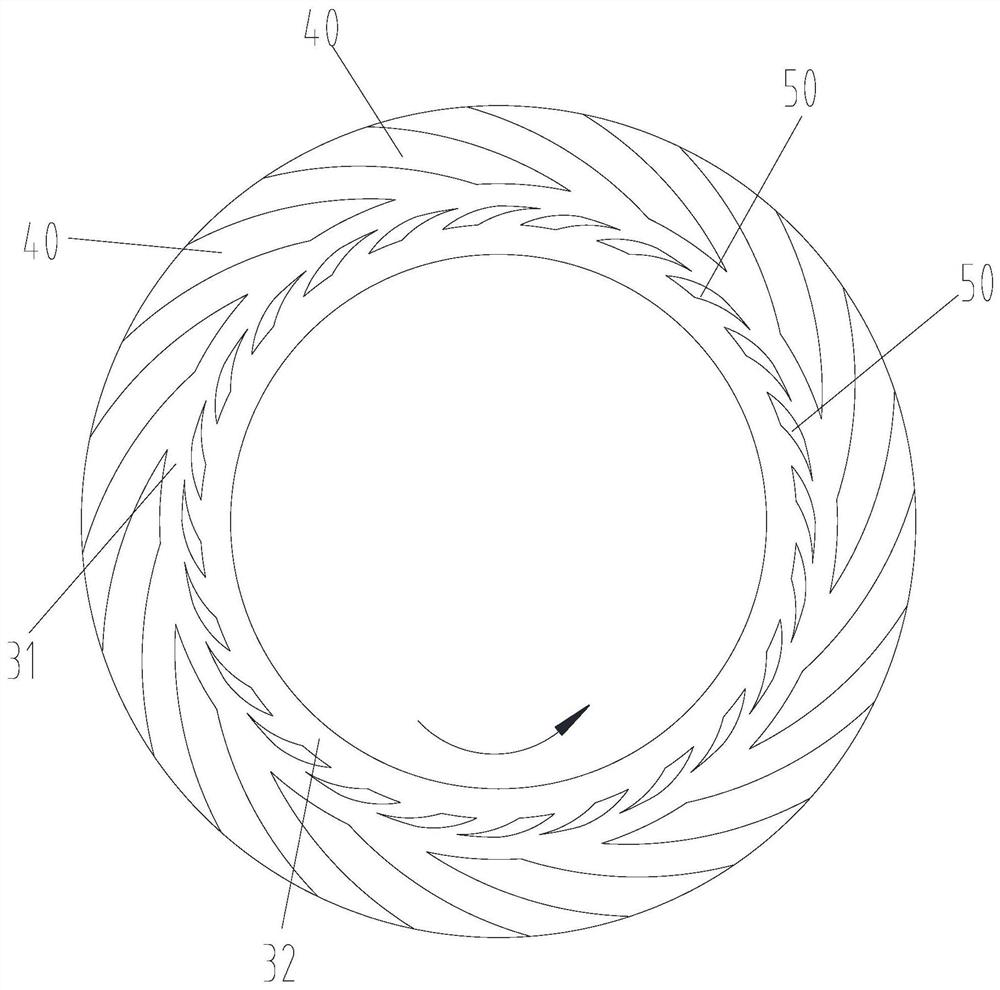

crankshaft and compressor

ActiveCN112943615BReduce exposureReduce direct frictionRotary/oscillating piston pump componentsLiquid fuel engine componentsMechanical engineeringLubrication

The invention provides a crankshaft and a compressor. The crankshaft includes a long shaft, an eccentric part and a short shaft connected in sequence. The end face of the short shaft is a thrust surface, and the thrust surface has an outer annular lubricating area and an inner annular lubricating area. The lubricating area is set around the inner annular lubricating area; among them, there are multiple outer lubricating grooves in the outer annular lubricating area, and the plurality of outer lubricating grooves are arranged at intervals along the circumference of the outer annular lubricating area; there are multiple inner lubricating grooves in the inner annular lubricating area , a plurality of inner lubricating grooves are arranged at intervals along the circumference of the inner annular lubricating area. When in use, the thrust surface of the crankshaft cooperates with the mating surface of the mating parts. When the crankshaft rotates, the gas and lubricating oil located outside the thrust surface enter the thrust surface and the mating surface through multiple external lubrication grooves and multiple internal lubrication grooves. Between them, a layer of fluid film is formed, which can avoid or reduce the contact and direct friction between the thrust surface and the mating surface, thereby reducing the wear of the crankshaft and mating parts, and improving the performance of the compressor using the above structure.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

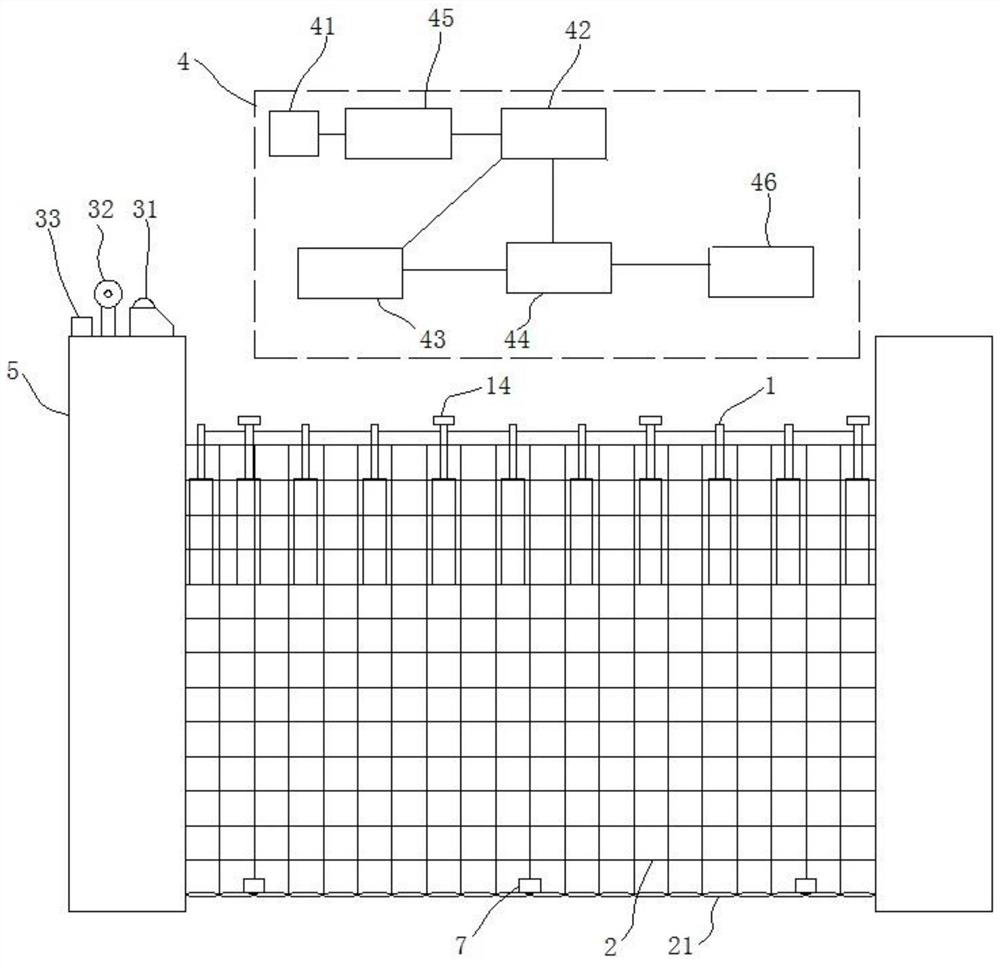

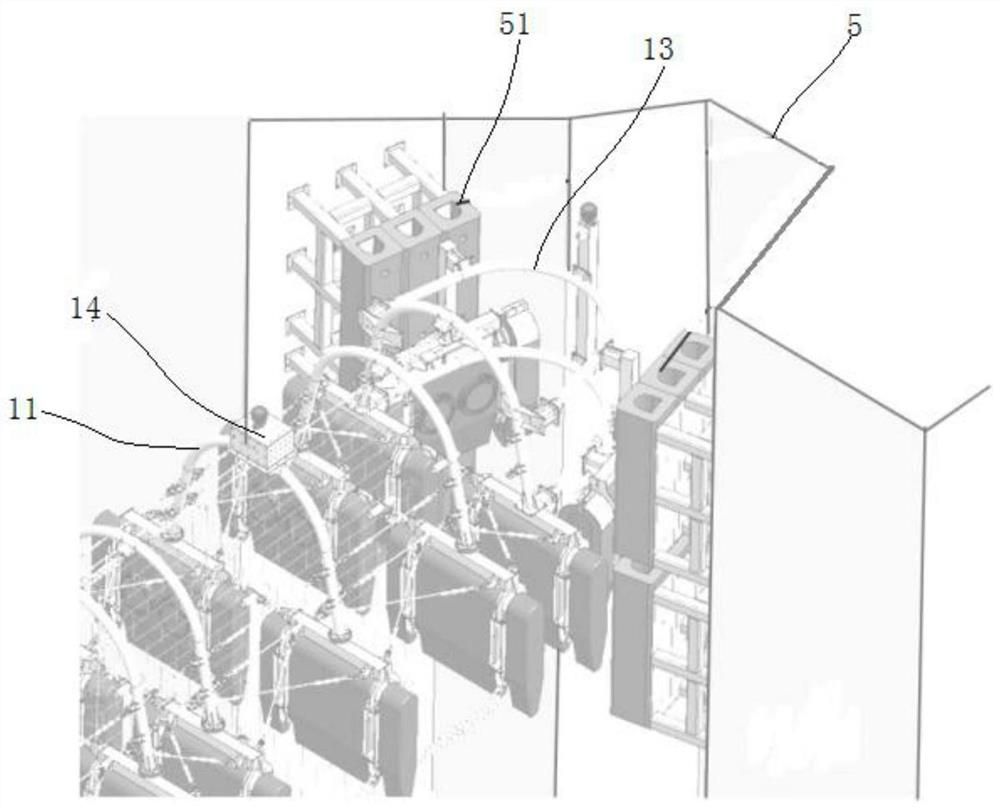

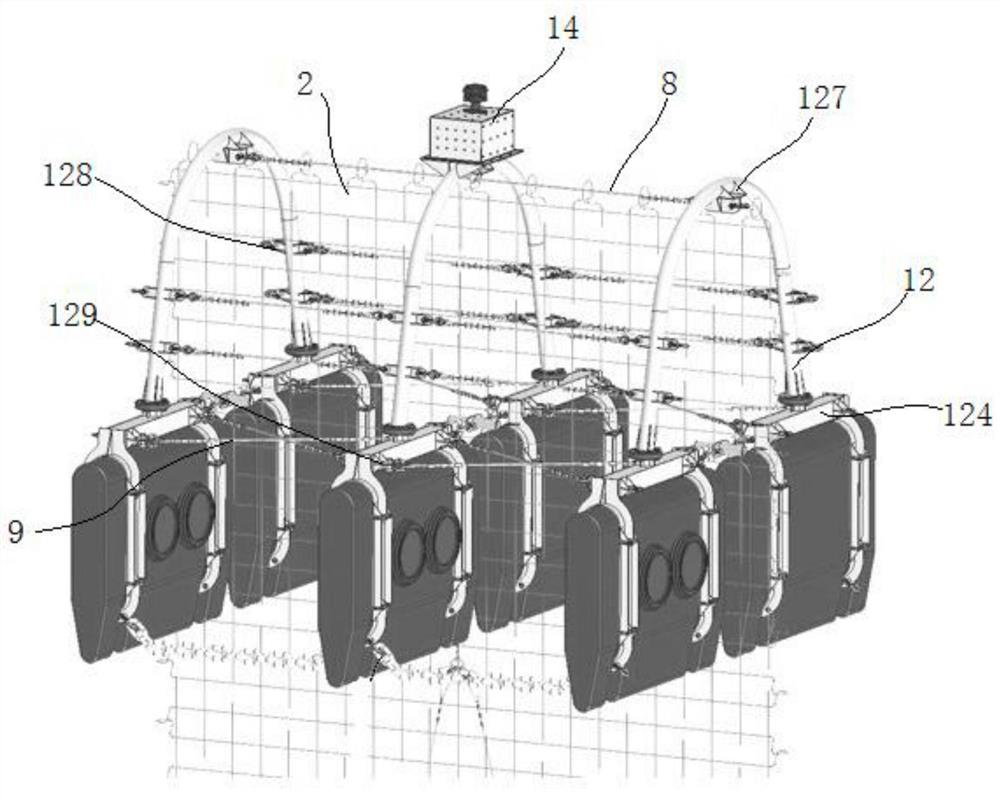

A port intelligent defense barrier system and its control method

ActiveCN111877252BRealize all-round defenseThere will be no safety hazards of entanglementWaterborne vesselsMarine site engineeringControl systemSignal generator

The invention discloses a port intelligent defense barrier system and a control method thereof, and relates to the technical field of port electronic protection. The concrete base of the system is set on both sides of the port, the floating door is placed horizontally on the water surface of the port, and one end is fixedly connected to the corresponding concrete base, and the other end is movably connected to the corresponding concrete base; the top of the floating door connection unit on the water is provided with Lifting the winch, the defense net is woven by photoelectric composite cables, the top of which is connected to the floating door on the water, and the bottom is anchored on the seabed through the counterweight anchor chain, and the tension sensor is set on the counterweight anchor chain; the defense net is connected with the The lifting winch is connected; the traction system is set on the top of the concrete base, the movable end of the traction cable of the floating gate traction winch bypasses the traction pulley and connects with the movable end of the floating gate on the water, and the control cabinet is connected with the signal of the traction winch of the floating gate; the control system consists of VTS control center, It consists of a signal generator, a signal analysis and detection device, a signal processing module, a signal receiving device and an alarm system.

Owner:云南保利天同水下装备科技有限公司

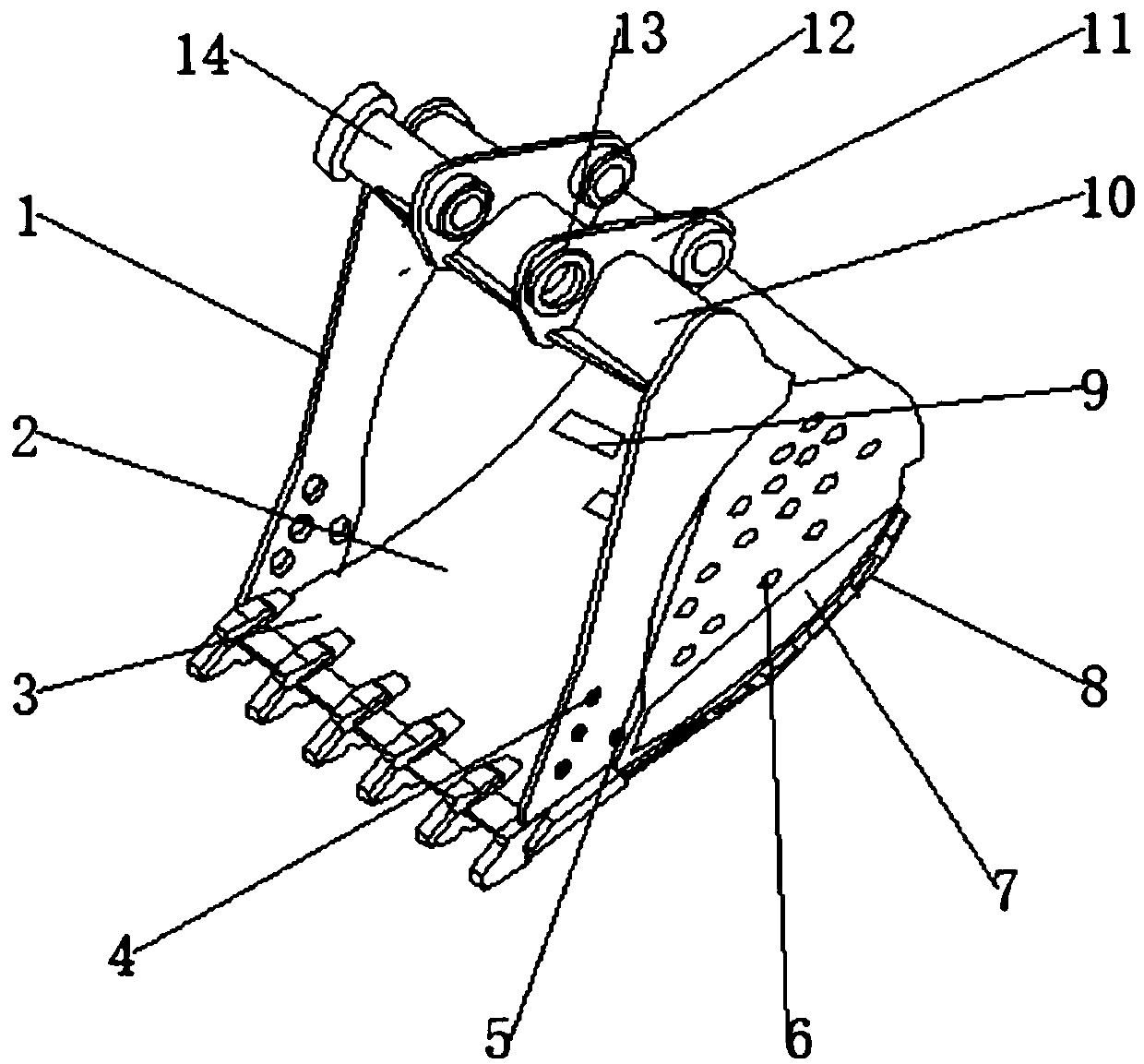

Agricultural excavator bucket

InactiveCN111197326AReduce resistanceImprove efficiencyMechanical machines/dredgersAgricultural engineeringHigh wear resistance

The invention discloses an agricultural excavator bucket. The agricultural excavator bucket comprises a bucket body, wherein a bucket inner container is arranged in the middle of the bucket body, inner container leakage holes are formed in the middle end of the bucket inner container, and base edges are arranged at one end of the bucket inner container, and both sides of the bucket inner containerare each provided with a bucket side plate; and a side wear-resistant plate is arranged at the bottom end of the side portion of the bucket side plate, side holes are formed in the side portion of one end of the bucket side plate, hemispherical bodies are arranged at the middle end of the side portion of the bucket side plate, a torque tube is arranged in the middle of the top end of the bucket side plate, and the middle of the top end of the torque tube is provided with a hinge plate. According to the agricultural excavator bucket, the wear-resistant plate is a plate prepared by compoundinga wear-resistant layer with high hardness and excellent wear resistance of a certain thickness on the surface of common low-carbon steel or low-alloy steel through a surfacing welding method, so thata good protection effect on the bucket main body can be achieved; and the outer surface of the arranged hemispherical bodies are very smooth, the direct friction with the sandy soil is reduced, the abrasion of the bucket main body is greatly reduced, and the service life of the bucket is greatly prolonged.

Owner:重庆博阔机械制造有限公司

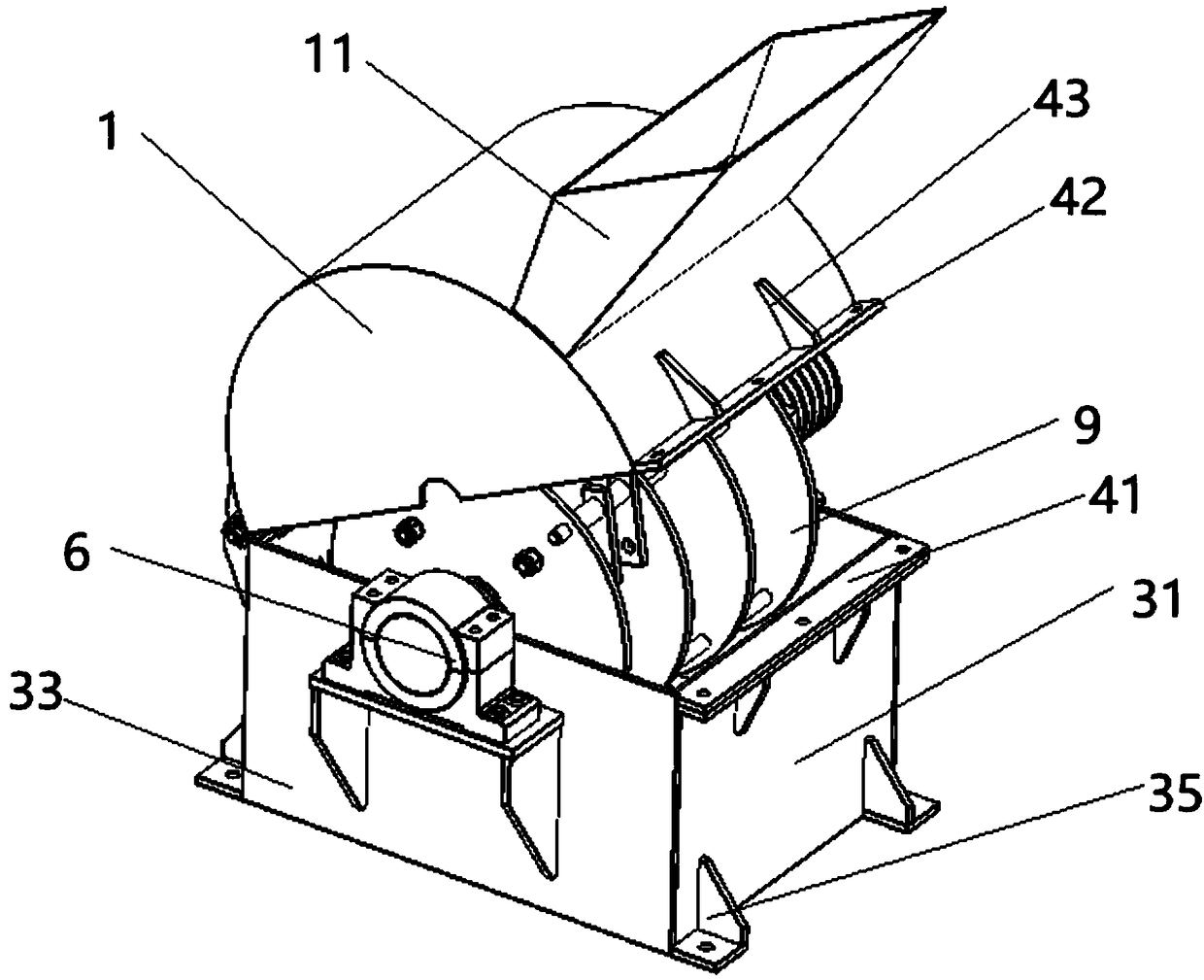

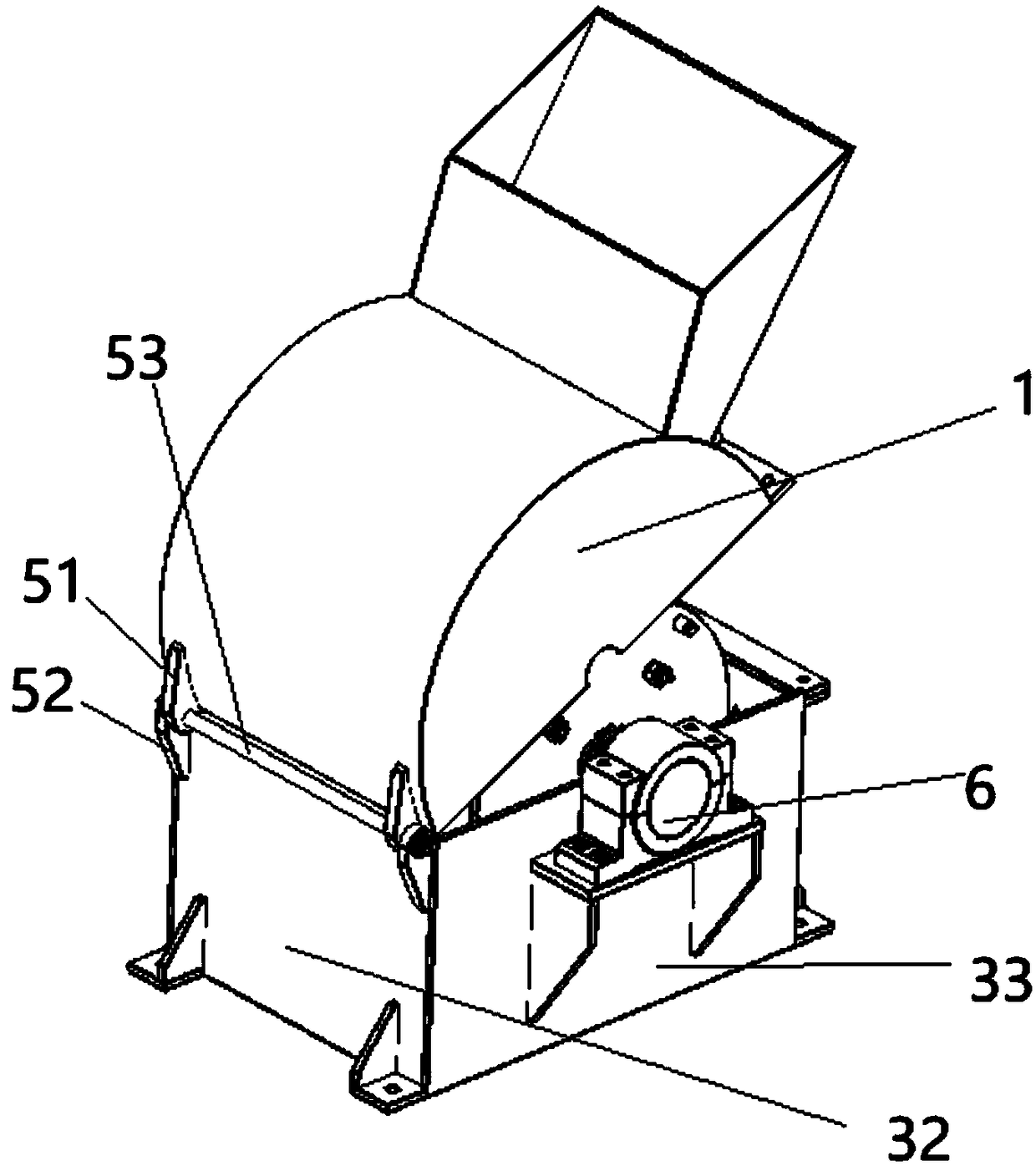

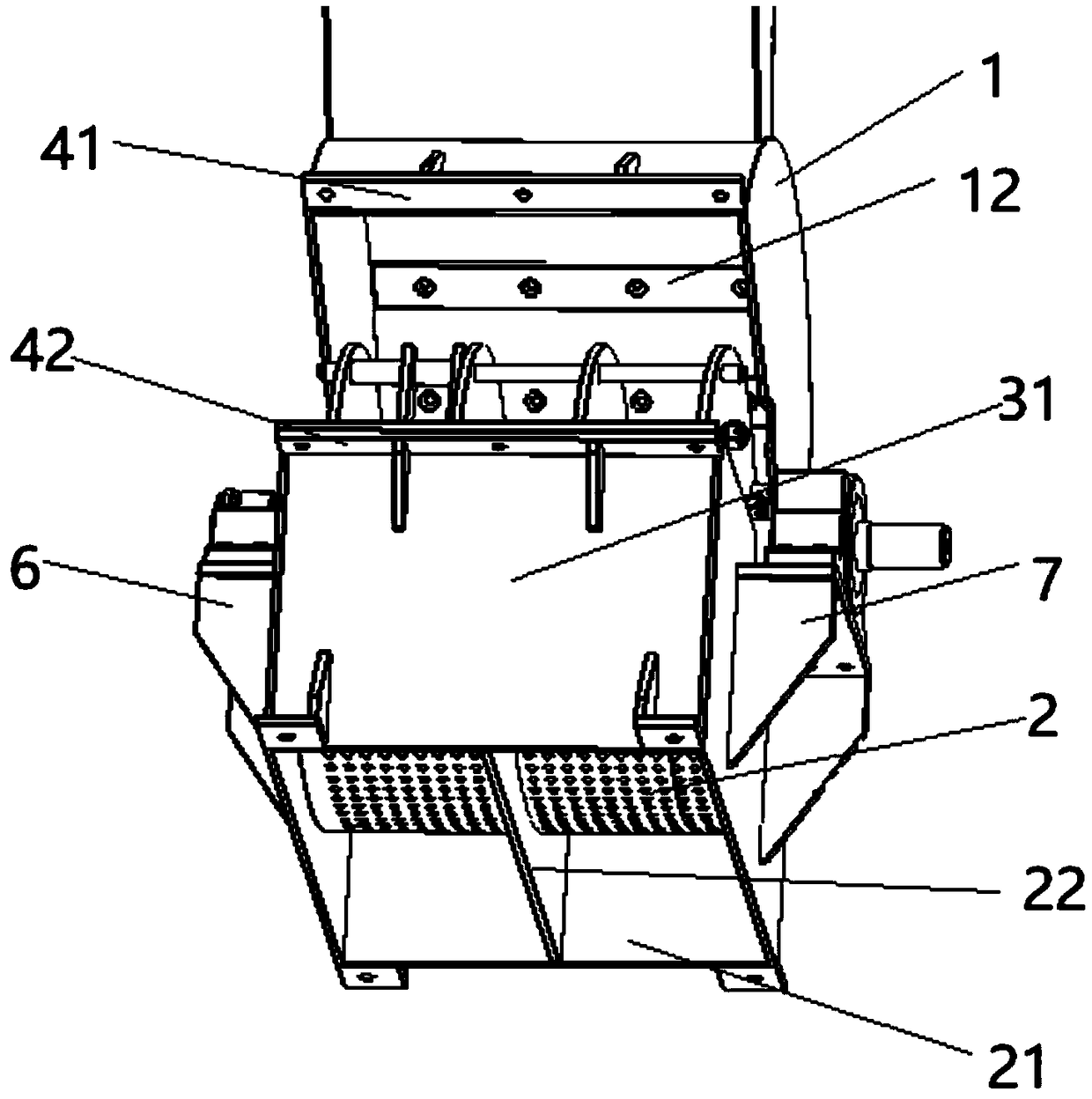

Small feed grinder

InactiveCN108816378AWith shock absorption and sound insulation effectGood shock absorption and sound insulationFeeding-stuffGrain treatmentsManufacturing technologyEngineering

The invention discloses a small feed grinder. The small feed grinder comprises a shell, the shell comprises an upper shell and a lower shell, a feeding port is connected to the upper portion of the upper shell, and lining plates are fixed to the inner side of the upper shell; square side plates are arranged at the periphery of the lower shell in an enclosing mode and comprise a front side plate, aback side plate, a left side plate and a right side plate, the two sides of the back edge of the upper shell are provided with first hinges, the two sides of the upper edge of the back side plate areprovided with second hinges, and the first hinges and the second hinges are connected through pin shafts in a penetrating mode; a right transmission device is connected to the right side plate, the structure of the right transmission device is the same as that of a left transmission device, and the right transmission device and the left transmission device are connected through a rotor shaft; andblades are arranged in the shell. According to the small feed grinder, the shell and the square side plates with the good vibration reduction and sound insulation effects are adopted, therefore, vibration is reduced, and noise is reduced; the closed opening type shell structure and an opposite opening are adopted, and therefore dust is reduced. The small feed grinder is simple in structure and manufacturing technology, high in practicability and wide in application range.

Owner:嘉兴溢联环保科技股份有限公司

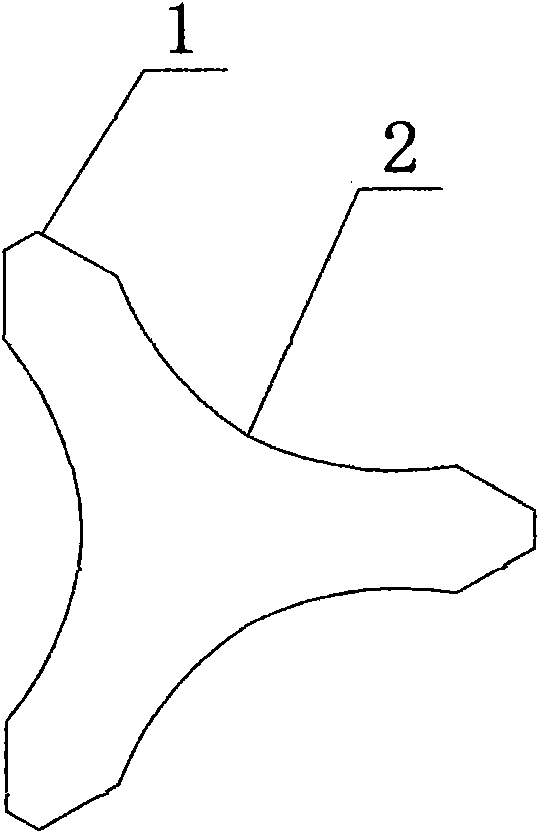

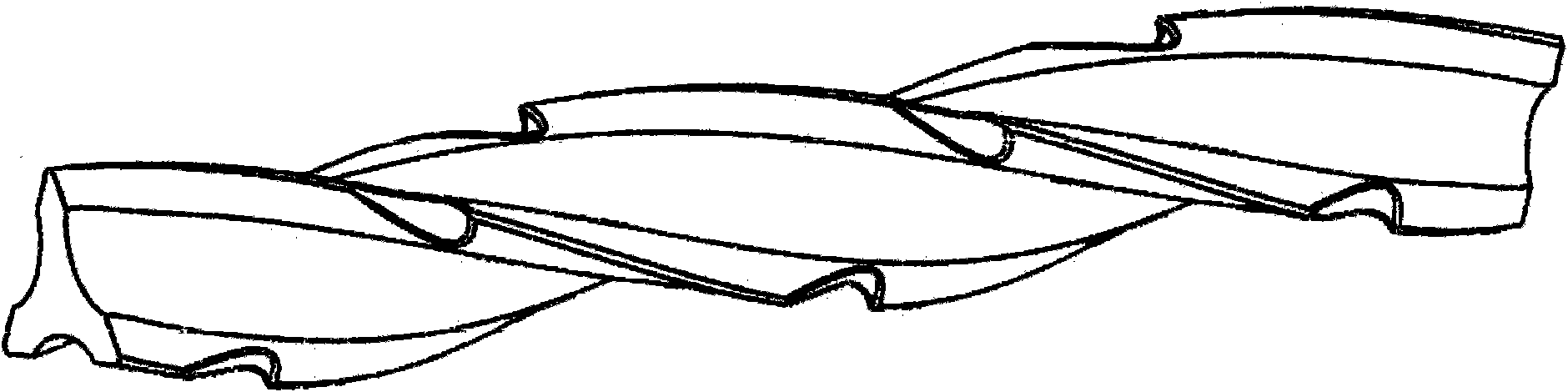

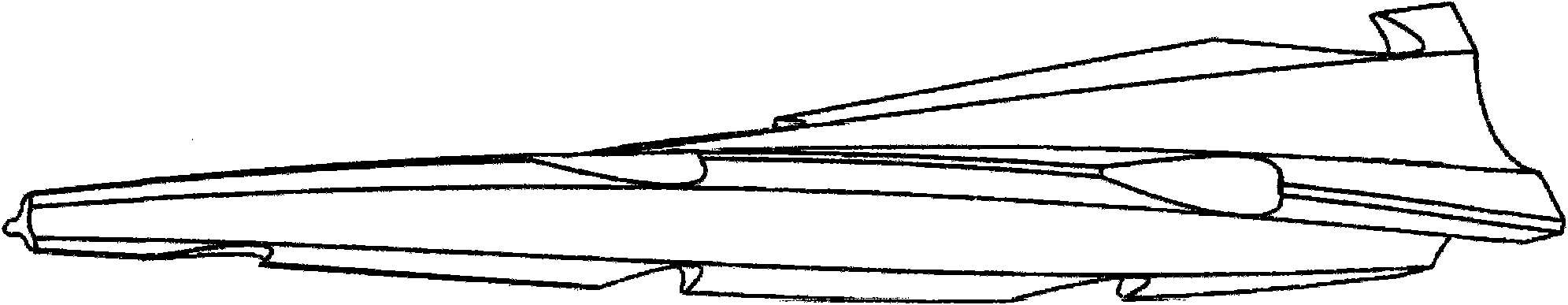

Rifle-shaped felting needle

The invention relates to a rifle-shaped felting needle. The felting needle consists of a needle rod, a middle section and a working section which are integrated; the ridge of the working section is rifle-shaped; and fiber storage grooves are formed between the adjacent ridges. The designed needle form is particularly suitable for weaving of thick and compact fibers, and weaving of nonwoven fabric which has high fragility (such as ceramic fiber, glass fiber and the like) or nonwoven fabric which has high friction force (such as carbon fiber, stainless steel fiber, aramid fiber, high-strength polyethylene fiber and the like). The felting needle can be used for weaving carbon fiber members used for aerospace.

Owner:青岛锦钻针业有限公司

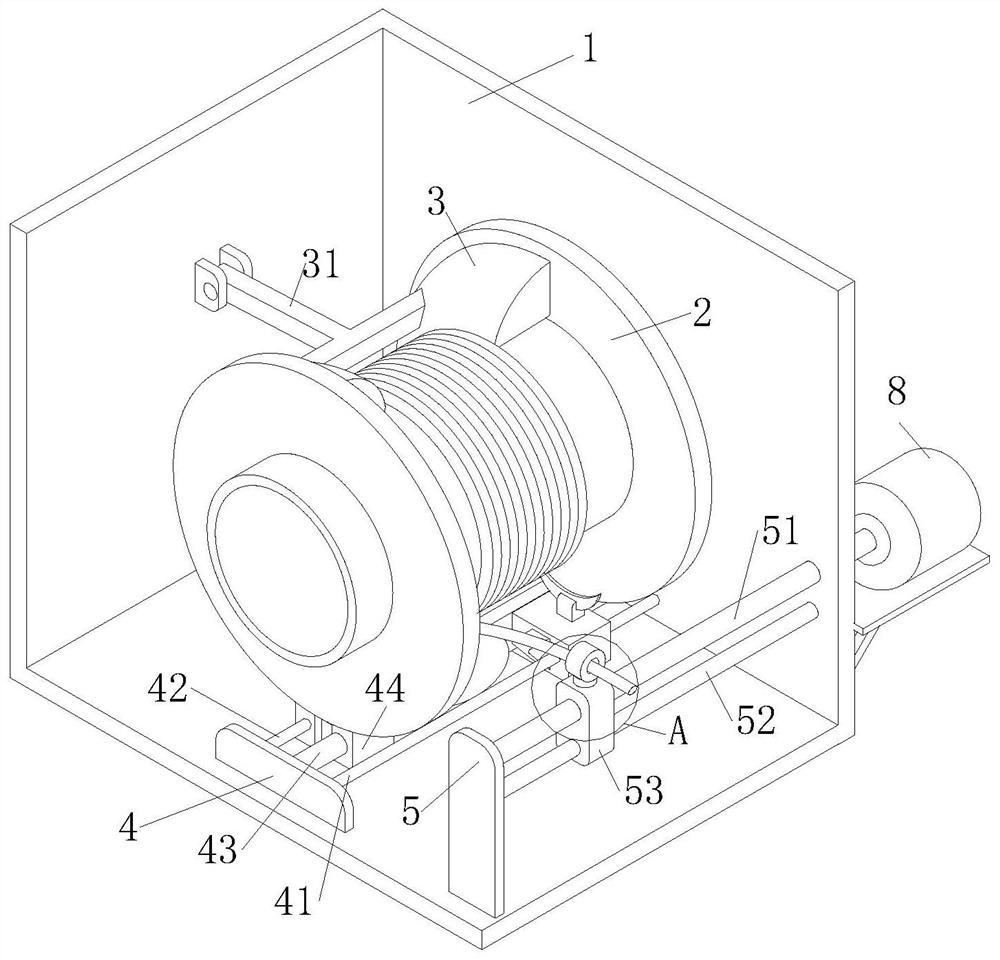

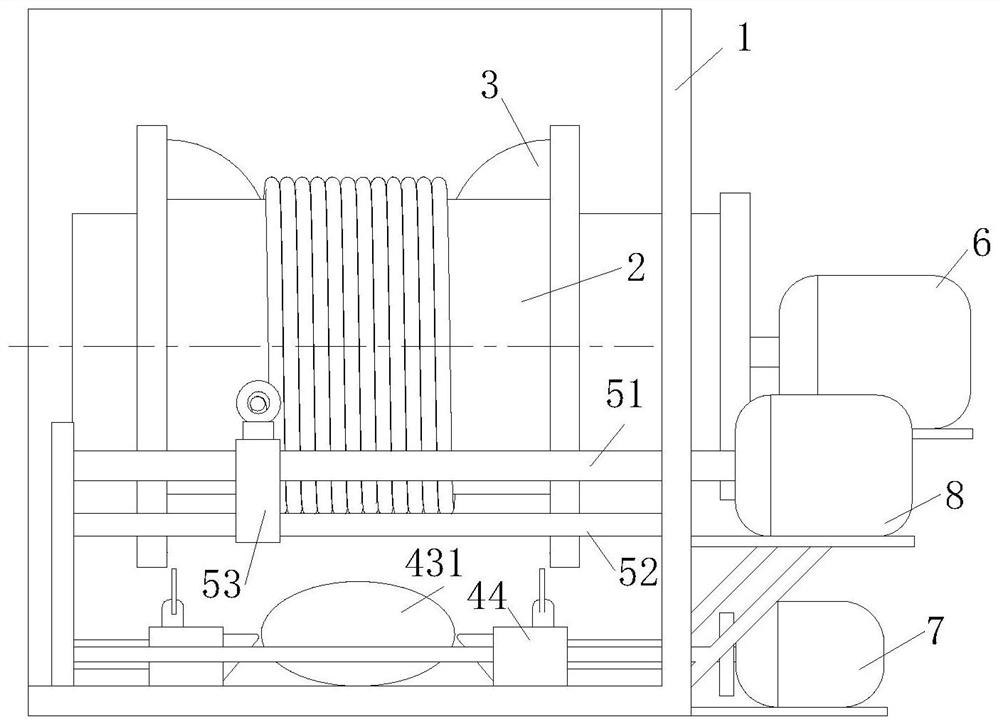

Welding wire speed regulation control system

InactiveCN111843121AEasy to tightenResolving entangled mess situationsWelding accessoriesControl systemElectric machinery

The invention relates to the technical field of welding equipment, and particularly relates to a welding wire speed regulation control system. The welding wire speed regulation control system comprises a rack, a wire reel, a guide block, a driving motor and a controller; the guide block is positioned at the upper part of the wire reel; a supporting block is arranged below the wire reel; a guide block is arranged on a path for withdrawing the welding wire to the wire reel; and the guide block, the supporting block, the guide block and lead screw pairs of the guide block, the supporting block and the guide block form a welding wire control system together with the driving motor and the controller. When the wire reel rotates to take back the welding wire, the welding wire is wound on the wirereel in a disordered manner, so that the wire feeding rate of the welding wire during reuse is influenced; therefore, through cooperation of the guide block, the supporting block and the guide blockwhich are arranged on the rack, the winding area, the winding strength and the initial winding angle of the welding wire during wire winding are limited, the problem that the welding wire is wound disorderly during wire winding of the wire reel is solved, and the conveying rate of the welding wire in subsequent use is stabilized.

Owner:TONGLING TONGFEI TECH

Wide View Side Shift Forks

The invention relates to the field of forklifts, in particular to a wide-field-of-view sidesway fork positioner. The wide-field-of-view sidesway fork positioner comprises a front pallet fork carrier, a rear pallet fork carrier, a left pallet fork and a right pallet fork. The rear pallet fork carrier comprises two opposite vertical column plates. The portion between the two vertical column plates is sequentially connected with an upper cross beam, a middle cross beam, a stopper chain plate and a lower cross beam from top to bottom. Two side plates are symmetrically arranged on the opposite sides of the two vertical column plates. Two shaft brackets are symmetrically arranged on the upper portions of the two side plates. Two adjusting supports are symmetrically arranged on the lower portions of the two side plates. Adjusting gaskets are installed in the adjusting supports. A sidesway oil cylinder rear support is arranged at the position, between the corresponding shaft bracket and the corresponding adjusting support, of one side plate. By means of the wide-field-of-view sidesway fork positioner, the overall field of view for sidesway distance adjustment of a forklift can be widened, and operating safety is improved; the structures of the front pallet fork carrier and the rear pallet fork carrier are more reasonable, fewer weld joints are generated, the machining difficulty is lowered, and assembly and adjustment are simpler; and the maintenance cost is reduced, and market competitiveness is improved.

Owner:ANHUI HELI CO LTD

Pulley device of conveyor

The invention discloses a pulley device of a conveyor, which comprises a fixing hole, a bolt hole, a bolt, a second baffle, a nut, a fixed wheel, a suspended ceiling, a fixing bolt, a first baffle, a fixing frame, a pin, a circular cylinder, and a pulley , Pulley groove. The present invention is simple in structure and low in cost. Through the action of the pulley, the direction of the force is changed, the friction is reduced, and the movement of the heavy object is realized in a labor-saving and quick manner. It is arranged inside the pulley, and the circular roller is fixed on the fixed wheel through the pin and the nut, which reduces the direct friction between the pulley and the pin, thus achieving labor-saving effect and more flexible operation. The bolts, bolt holes, and fixing bolts are mutually combined and fixed, and are in a movable connection relationship, and can swing in a small range, making the invention more flexible and stable.

Owner:全南县智护力工业产品设计有限公司

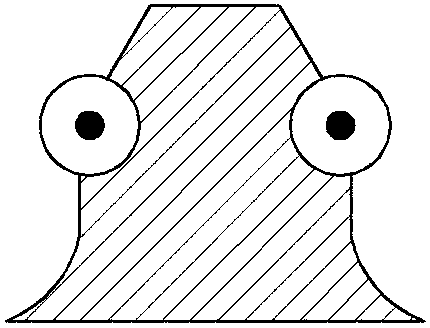

Front axle hub

The invention belongs to the technical field of automobile part tools, and particularly relates to a front axle hub. The front axle hub comprises a cylindrical wheel body, wherein a protruding part is arranged on the front side of the cylindrical wheel body, arc transition is adopted between the protruding part and the cylindrical wheel body, the top end of the protruding part is a plane, the diameter of a column hole is larger than that of a cylindrical hole, an upper gear is arranged at the position where an upper hole is connected with a middle hole, and a lower gear is arranged at the position where a lower hole is connected with the middle hole. Compared with the prior art, the front axle hub has the advantages that the structure is simple, abrasion between a front axle and the front axle hub can be reduced greatly, using strength can be improved greatly, and service life can be prolonged.

Owner:ZHEJIANG LONGHU FORGING

Automobile application gear

InactiveCN108458086AHigh strengthEasy and smooth workGear lubrication/coolingPortable liftingAlloyEngineering

The invention discloses an automobile application gear, and belongs to the field of gears. The automobile application gear comprises a gear, gear teeth, rollers, oil outlets, tooth spaces, a flaw detector, a shaft hole, oil guide through holes and a key groove, wherein the center of the gear is designed as the shaft hole; the key groove is formed in the shaft hole; the oil guide through holes areformed in an I-shaped groove of the gear; the flaw detector is arranged on the inner tooth edge of the gear; the gear teeth are uniformly distributed on the outer tooth edge of the gear; the rollers are arranged at the two sides of each gear tooth; the tooth space is arranged between each two gear teeth; and the oil outlet is arranged in each tooth space. The automobile application gear has the beneficial effects that the automobile application gear adopts an I-shaped structure; the strength of the gear is greatly intensified on the basis of saving materials; the gear is relatively light and smooth when the gear works; the hard alloy rollers are arranged on the gear teeth of the gear; and as the rollers are directly contacted during the gear teeth meshing, the direct friction of the gear teeth is reduced.

Owner:常州华凯石墨烯应用科技有限公司

Stripe type wear resistant grinding roller for vertical mill

The invention discloses a stripe type wear resistant grinding roller for a vertical mill. The stripe type wear resistant grinding roller comprises a conical roller body, and multiple wear resistant stripes uniformly arranged on the outer surface of the conical roller body in the generatrix direction; temporary filling grooves are formed between every two adjacent wear resistant stripes; and material cushion layers are filled in all the temporary filling grooves, and are materials machined by the vertical mill. The stripe type wear resistant grinding roller for the vertical mill is surfaced with the wear resistant stripes with various shapes on the smooth surface, so that the friction force is increased, the materials are uniformly distributed between the grinding roller and a grinding disc under the effect of centrifugal force, the friction between the materials and the grinding disc is reduced, the grinding efficiency is improved, and the service life of the grinding roller is prolonged.

Owner:JIANGSU HAIJIAN

Safe and reliable lamp holder mold

The invention discloses a safe and reliable lamp holder mold. The safe and reliable lamp holder mold comprises a panel, an upper mold base, screw rods, a water gap plate, square iron, a lower mold base, a bottom plate, a guide column, a limiting block, a pressing block, a connecting block, a chain, a motor, fixing columns, a fine water gap sprue, an air purification chamber, a pin, a sliding column, a limiting baffle, positioning bolts, a mounting plate, a rotor, an extrusion module and an ejector pin. The rotor is installed at the upper position of the middle of the square iron, the screw rods are evenly distributed in the middle of the water gap plate, and the fine water gap sprue is formed in the middle of the panel. The safe and reliable lamp holder mold is novel in structure, reasonable in design, easy to manufacture, convenient to operate, safe to use, low in consumption cost and high in work efficiency; the upper mold base, the lower mold base and other components are arranged,so that the lamp holder mold is convenient to install and fix; and the air purification chamber is arranged, so that air around the lamp holder mold is convenient to purify through material treatment,the precision in the mold closing process is guaranteed, and the machining precision of products is improved.

Owner:东莞市纳百医疗科技有限公司

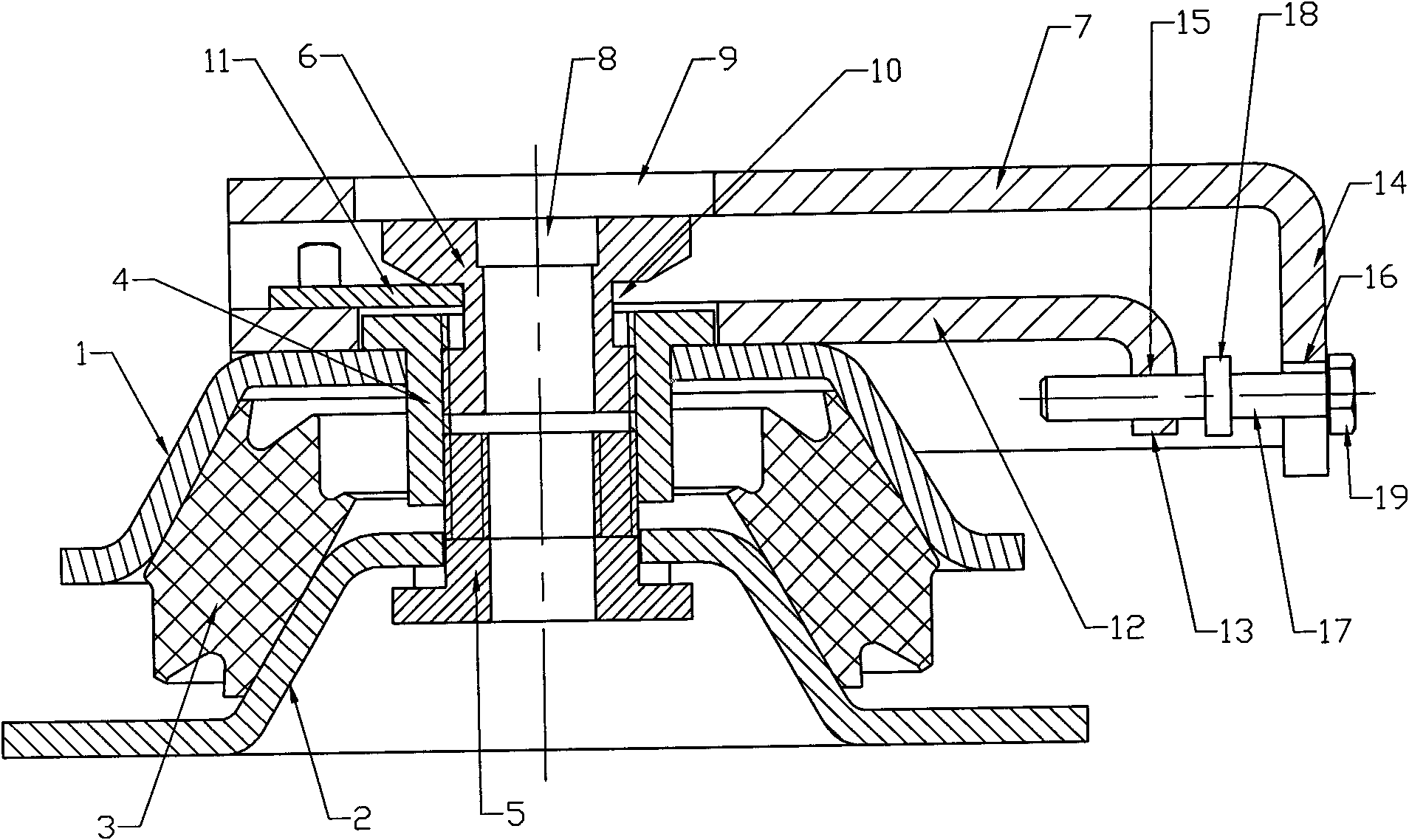

Large engine crankshaft CNC grinding machine

ActiveCN104044024BReduce direct frictionHigh precisionRevolution surface grinding machinesGrinding drivesCnc grindingDistributor

The invention relates to a numerically controlled large engine crankshaft grinder, which comprises a main bed, an axial grinding machine movement track is arranged on the main bed, an axial moving carriage is slidably connected with the axial grinding machine movement track, and a grinding machine assembly is slidably connected with the axial moving carriage; a main track is arranged on the main bed, a spindle head mechanism and a spindle tail mechanism are slidably connected with the main track, a first driver is connected with the bottom of the spindle head mechanism, the spindle head mechanism comprises a spindle box and a spindle mounted in the spindle box, a fixture mechanism is fixed on the front end of the spindle, an oil distributor is fixed on the rear end of the spindle, a motor rotor and a motor stator which cooperate with each other and are arranged in the spindle box are sleeved on the spindle, and the center of the front end of the spindle is provided with a centre. The numerically controlled large engine crankshaft grinder increases production efficiency, and provides a reliable guarantee for product quality.

Owner:湖北伟翔数控机床股份有限公司

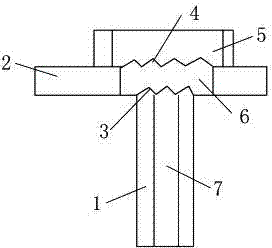

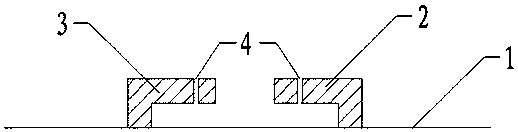

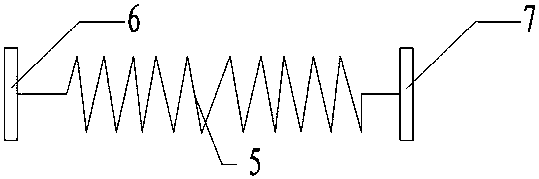

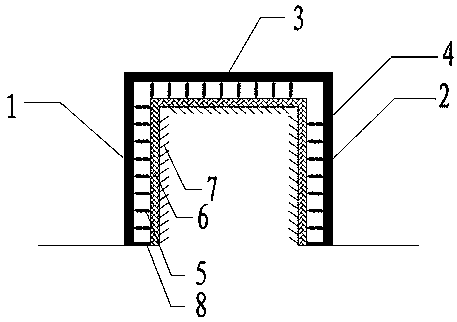

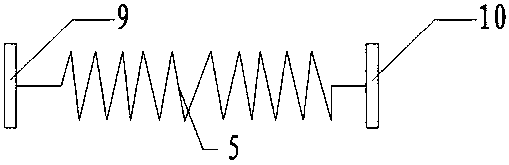

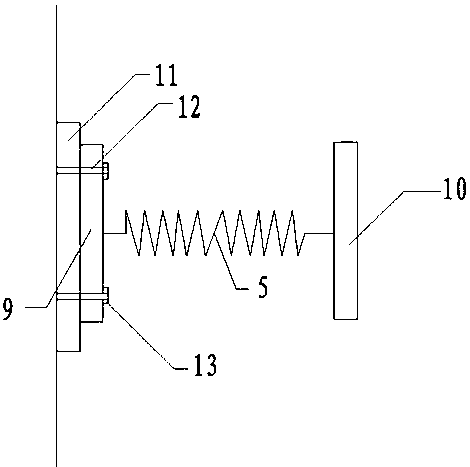

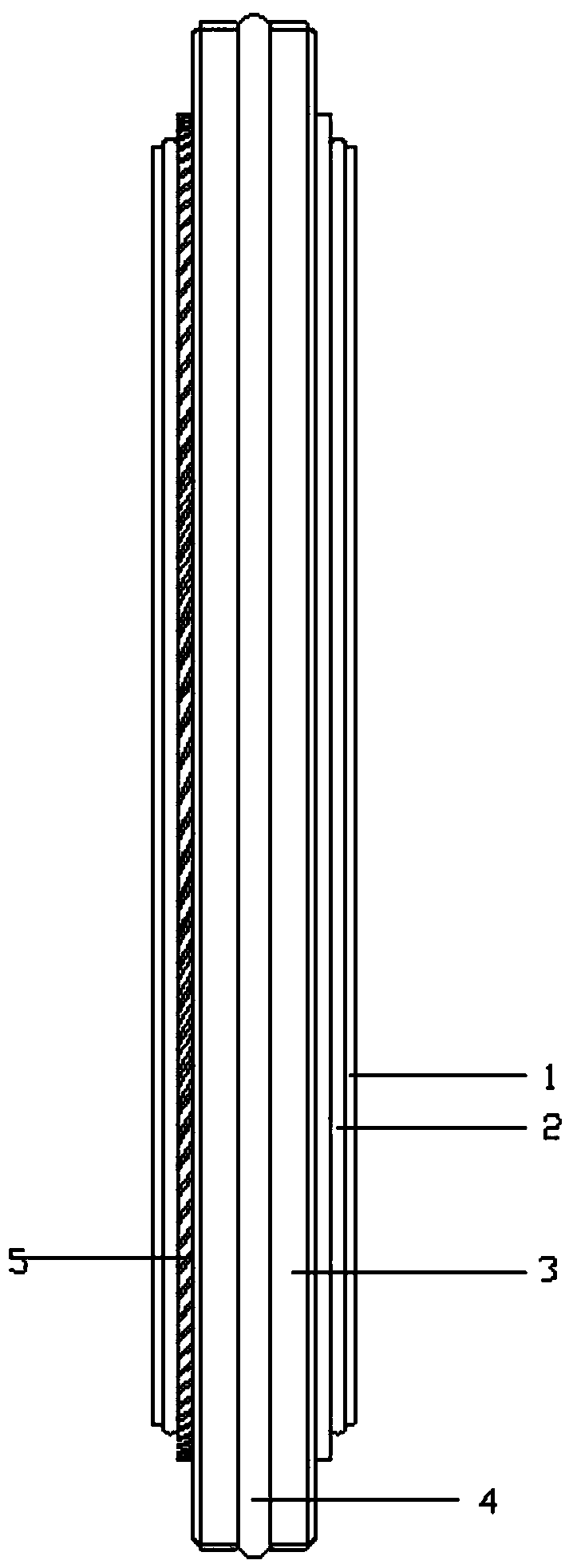

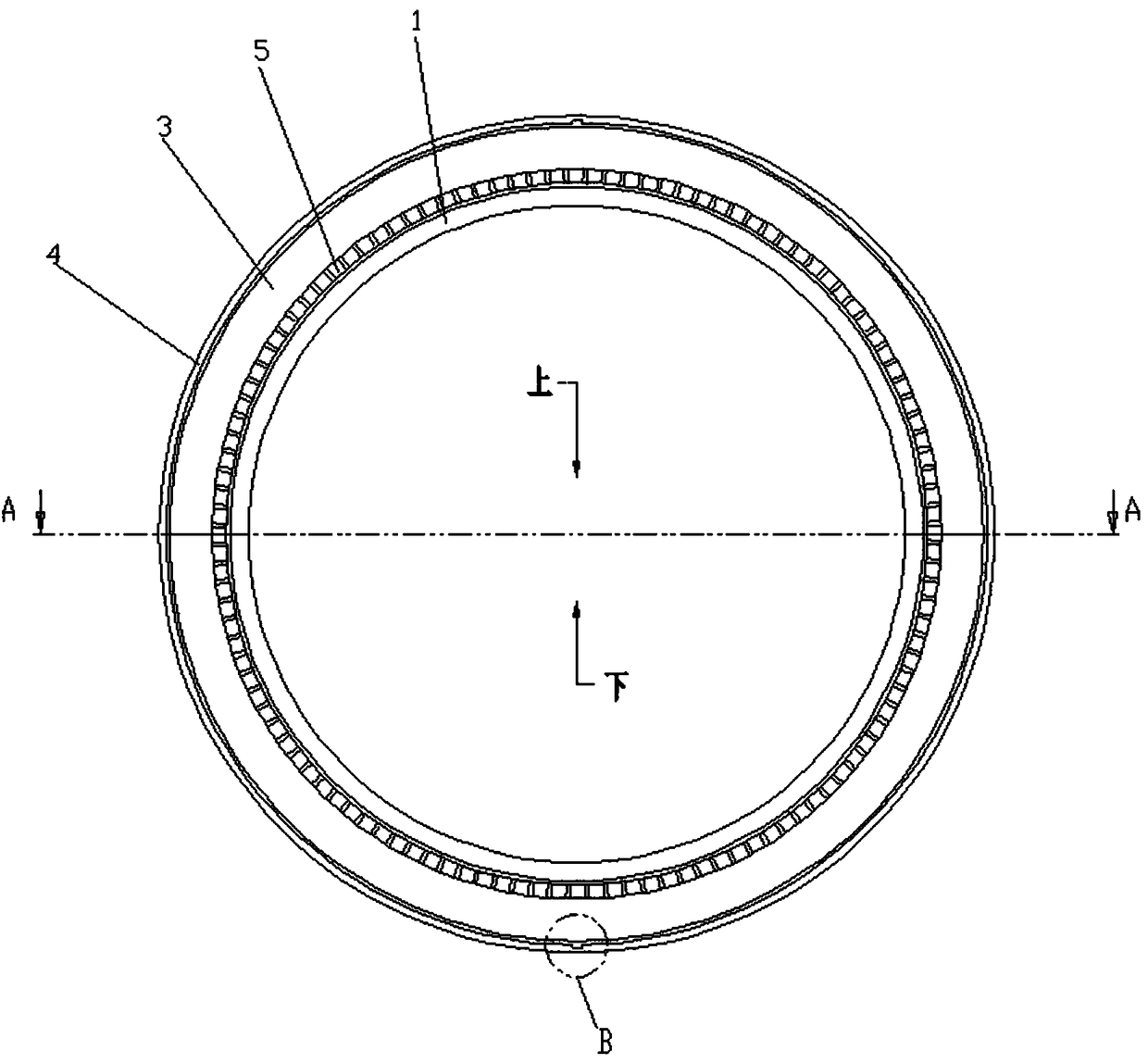

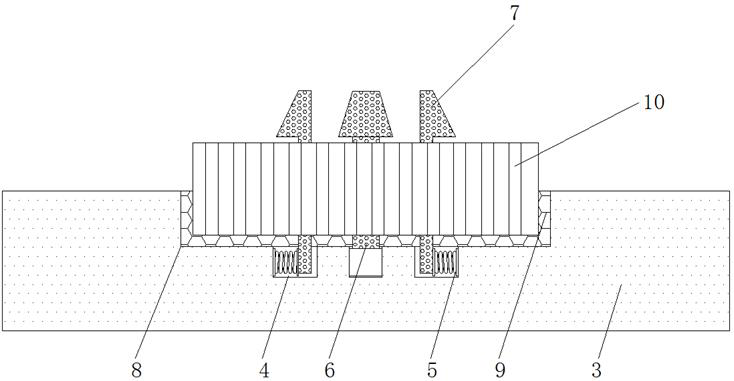

Spring installing and fixing structure and gate groove anti-abrasion device applying same

The invention provides a spring installing and fixing structure and a gate groove anti-abrasion device applying the spring installing and fixing structure. An installation foundation support is weldedto a steel plate, the two ends of a spring are provided with fixing plates, the fixing plates and the installation foundation support are all provided with bolt holes to realize bolt connection, andthe spring is convenient to detach and install. The steel plate of the U-shaped structure, a Teflon sliding plate and the spring are arranged, a gate structure is lifted conveniently, and collision generated in the work process of the gate can be subjected to energy depletion conveniently; secondly, by means of a bristle structure arranged on the Teflon sliding plate, direct friction to the sliding plate is reduced; and moreover, the flexible bristles contribute to weakening of energy, and the anti-abrasion effect of the structure is improved.

Owner:HENAN SHANGYU ELECTROMECHANICAL EQUIP MFG CO LTD

Construction method for protecting gate groove for water conservancy project

PendingCN108316252AImprove wear resistanceReduce direct frictionBarrages/weirsHydro energy generationTetrafluoroethyleneArchitectural engineering

The invention provides a construction method for protecting a gate groove for a water conservancy project. According to the construction method, a steel plate with a U-shaped structure, a tetrafluoroethylene sliding plate and first springs are arranged, so that lifting of gate structure is facilitated, and energy consumption of collision generated in the gate working project is also conveniently reduced; and then, brush structures arranged on the tetrafluoroethylene sliding plate reduces direct friction to the sliding plate, and flexible brush hair is beneficial to weakening energy, and therefore the anti-wear effect of the structure is improved.

Owner:郑州誉善贸易有限公司

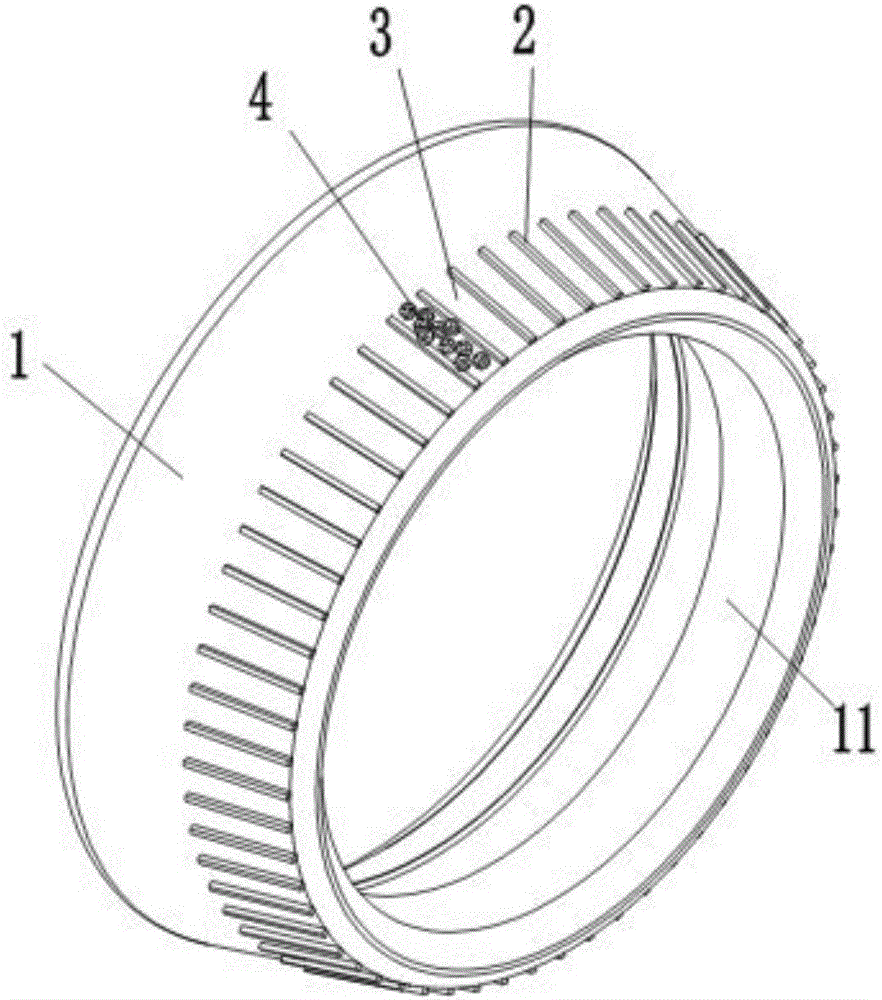

A sealing device for a high-speed motor

ActiveCN106505777BReduce direct frictionExtended service lifeSupports/enclosures/casingsEngineeringMechanical engineering

The invention relates to a sealing apparatus for a high-speed motor. The sealing apparatus comprises an oil sealing inner ring and an oil sealing outer ring, wherein the oil sealing inner ring is arranged on a motor main shaft in a sleeving manner; a ring of first concave-convex groove structure is arranged in the middle position of the outer wall of the oil sealing inner ring; a ring of second concave-convex groove structure matched with the first concave-convex groove structure is arranged on the inner wall of the oil sealing outer ring; the oil sealing outer ring is rotationally mounted on the periphery of the oil sealing inner ring through the matching between the first concave-convex groove structure and the second concave-convex groove structure; a positioning pin for fixing the oil sealing outer ring on a motor oil cover is also arranged on the oil seal outer ring; and the positioning pin enables the oil sealing outer ring not to rotate along the oil sealing inner ring in the operating of the motor. The sealing apparatus has the beneficial effects of greatly reinforcing the sealing effect and reducing direct friction on the main shaft by oil sealing, thereby prolonging the service life of the main shaft.

Owner:GUANGXI HENGDA ELECTRIC MACHINE TECH CO LTD

Bicycle shock absorption component and bicycle

The invention relates to a bicycle shock absorption component which comprises a bicycle frame and a pedal device, wherein the pedal device comprises a rear fork component and a pedal component; a connecting hole is formed in the bicycle frame and internally provided with a connecting shaft; bulges are arranged on the connecting shaft; a shock absorption piece is arranged on the connecting shaft; the shock absorption piece is connected with the bicycle frame; the connecting hole is internally provided with at least two limiting baffles; a clearance allowing the bulges to move is formed between every two adjacent limiting baffles; the rear fork component is arranged at the two ends of the connecting shaft; wear-proof gaskets are arranged at the two ends of the connecting shaft; the pedal component is arranged on the connecting shaft. The bicycle shock absorption component has the advantages that the shock absorption piece is arranged on the connecting shaft and connected with the bicycle frame, so that vibration generated when a bicycle is ridden on a non-ideal terrain can be effectively reduced; vibration conducted to people is reduced; riding is more comfortable; the bicycle can be protected; a service life of the bicycle is prolonged. In addition, the invention further provides a bicycle which comprises the shock absorption component.

Owner:楼蕾

A front axle hub

ActiveCN103935187BReduce direct frictionFirmly connectedHubsUltimate tensile strengthAutomotive engineering

Owner:ZHEJIANG LONGHU FORGING

High-strength lifting lug for elevator box

The invention relates to the technical field of elevator lifting, and discloses a high-strength lifting lug for an elevator box. The high-strength lifting lug comprises a bearing plate, wherein two reinforcing rods penetrating through the bearing plate are fixedly installed inside the bearing plate, first nuts are in threaded connection with the outer sides of the reinforcing rods and located above the bearing plate, limiting plates are fixedly installed on the tops of the first nuts, second nuts are in threaded connection with the tops of the limiting plates and located on the outer sides of the reinforcing rods, and gaskets are fixedly installed on the outer sides of the two reinforcing rods and located at the bottom of the bearing plate. According to the high-strength lifting lug for the elevator box, by arranging a rotating shaft, a bearing and a rolling wheel, a steel cable lifting rope is in direct contact with the outer side of the rolling wheel inside the lifting lug, a concave groove is formed in the outer side of the rolling wheel, the radius of the concave groove is larger than the diameter of the steel cable lifting rope, direct friction between the steel cable lifting rope and the lifting lug can be reduced in the lifting process of an elevator, and the purpose of reducing friction between the lifting lug and the steel cable rope is achieved.

Owner:湖北惠天下建工科技股份有限公司

An anti-loose suspension fixing device for automobile spare tire

ActiveCN112172944BShorten the timeImprove travel efficiencySpare wheel arrangementsElectric machineryControl theory

Owner:XIAN NAISEN SPECIAL VEHICLE PRODN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com