Rifle-shaped felting needle

A technology of laiford thread and felting needle is applied in the field of equipment for producing non-woven fabrics, which can solve the problems of high friction coefficient, damage to the performance of non-woven fabrics, fiber damage, etc. The effect of pulling force and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

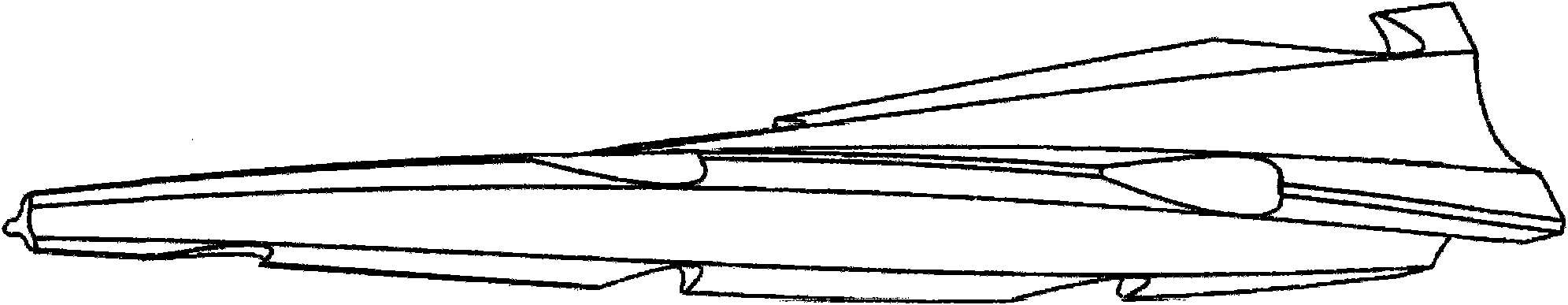

[0060] Specific embodiment 1: (single fiber storage tank)

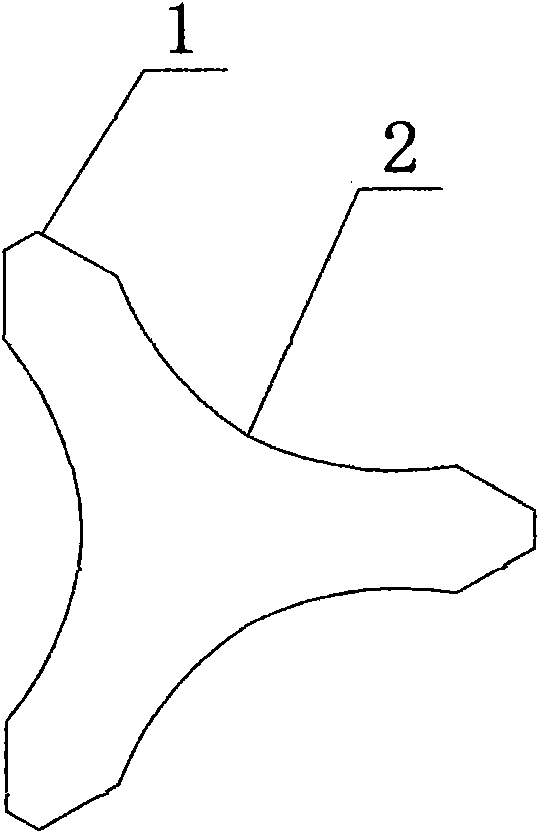

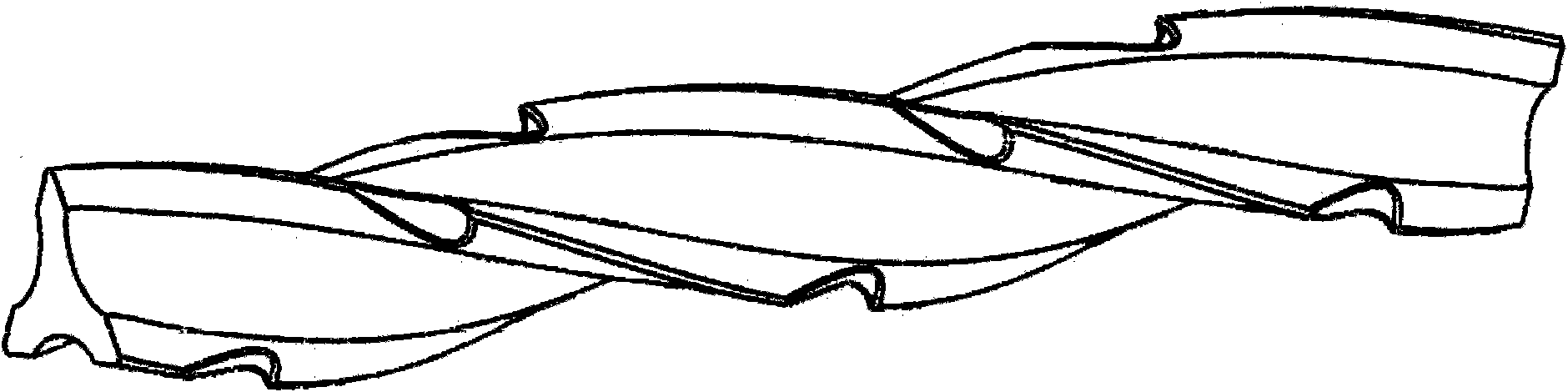

[0061] A rifle-shaped needle, composed of an integral needle shaft, a middle section and a working section, the ridge line 1 of the working section is in the shape of a rifle, and there is a gap between two adjacent ridge lines 1 Fiber storage tank 2. The fiber storage tank 2 is set as a groove, and at least one fiber storage tank 2 is arranged between two adjacent ridge lines 1 . The working section of the pricker is set in a triangular (conical) column shape, the ridge lines 1 of the working section are in the shape of a rifle, and a fiber storage tank 2 is arranged between two adjacent ridge lines 1, and the fiber storage tank 2 The cross-sectional shape is arc-shaped (such as Figure 1-3 shown), triangles (such as Figure 4-6 shown), trapezoidal (such as Figure 7-9 shown), rectangle (as shown in Figure 10-12).

[0062] The working section of the pricker is set in a square (cone) column shape, the ridge lines...

specific Embodiment 2

[0063] Specific embodiment 2: (double fiber storage tank)

[0064] The working section of the puncture needle is set as a triangular (conical) column, and both sides of the ridge line of the triangular column are provided with a fiber storage tank, and the cross-sectional shape of the fiber storage tank is arc-shaped (such as Figure 19-24 shown), triangles (such as Figure 25-27 As shown), trapezoid (as shown in Figure 28-30), rectangle (as shown in Figure 31-33), parabolic (as shown in Figure 34-36), involute (as shown in Figure 37-39).

[0065] The working section of the pricker is set in a star-shaped (tapered) column, and both sides of the longer-diameter ridge line of the star-shaped column are provided with fiber storage tanks (such as Figure 40-45 shown).

[0066] Barbed hooks are arranged on the ridge line, and the number of barbed hooks is set to 1-32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com