Front axle hub

A wheel hub and front axle technology, applied in the direction of wheel hub, transportation and packaging, vehicle parts, etc., can solve the problems of front axle wheel hub wear, large difference in material hardness, front axle wheel hub cracks, etc., to increase the service life and strengthen the use strength. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

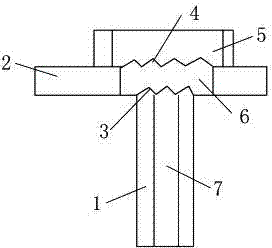

[0008] Combine below figure 1 Specific description embodiment:

[0009] A front axle hub, the front axle hub includes a cylindrical wheel body 1, the front of the cylindrical wheel body 1 is provided with a convex part 2, and the transition between the convex part 2 and the cylindrical wheel body 1 is through a circular arc , the top of the convex part 2 is a plane; the middle of the cylindrical wheel body 1 is provided with a through-hole structure, and the through-hole structure includes an upper hole 5, a middle hole 6 and a lower hole 7, and the upper hole 5 is a cylindrical hole protruding from the top plane, and the lower hole 7 is a column hole protruding from the back of the cylindrical wheel body 1, and the transition between the column hole and the back of the cylindrical wheel body is through a circular arc. The diameter of the column hole is greater than the diameter of the cylindrical hole; the junction of the upper hole 5 and the middle hole 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com