Small feed grinder

A pulverizer and feed technology, which is applied in feed, grain processing, food science, etc., can solve the problems of dust damage to the human body, high vibration frequency, and easy wear of the frame, and achieve simple manufacturing process, dust reduction, and vibration reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

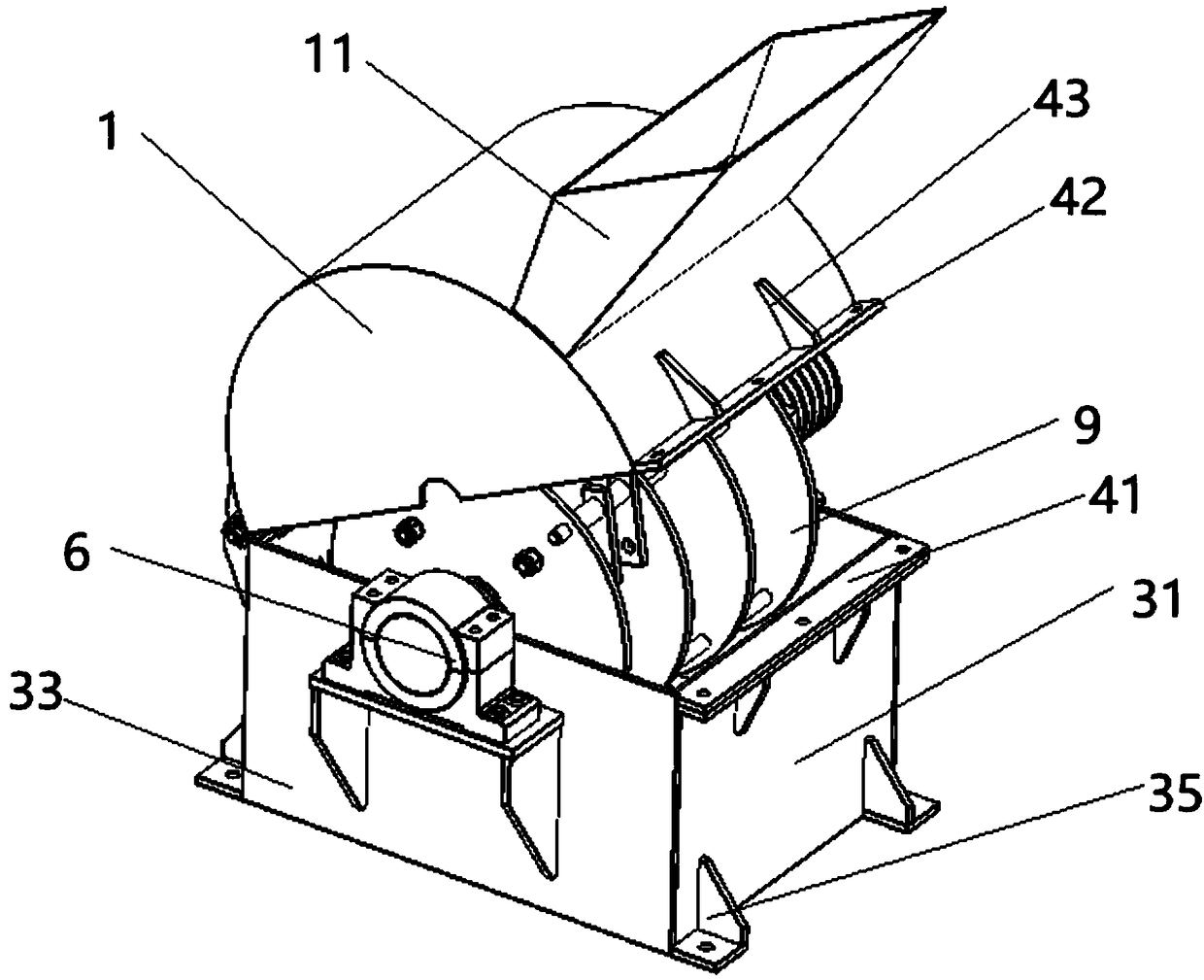

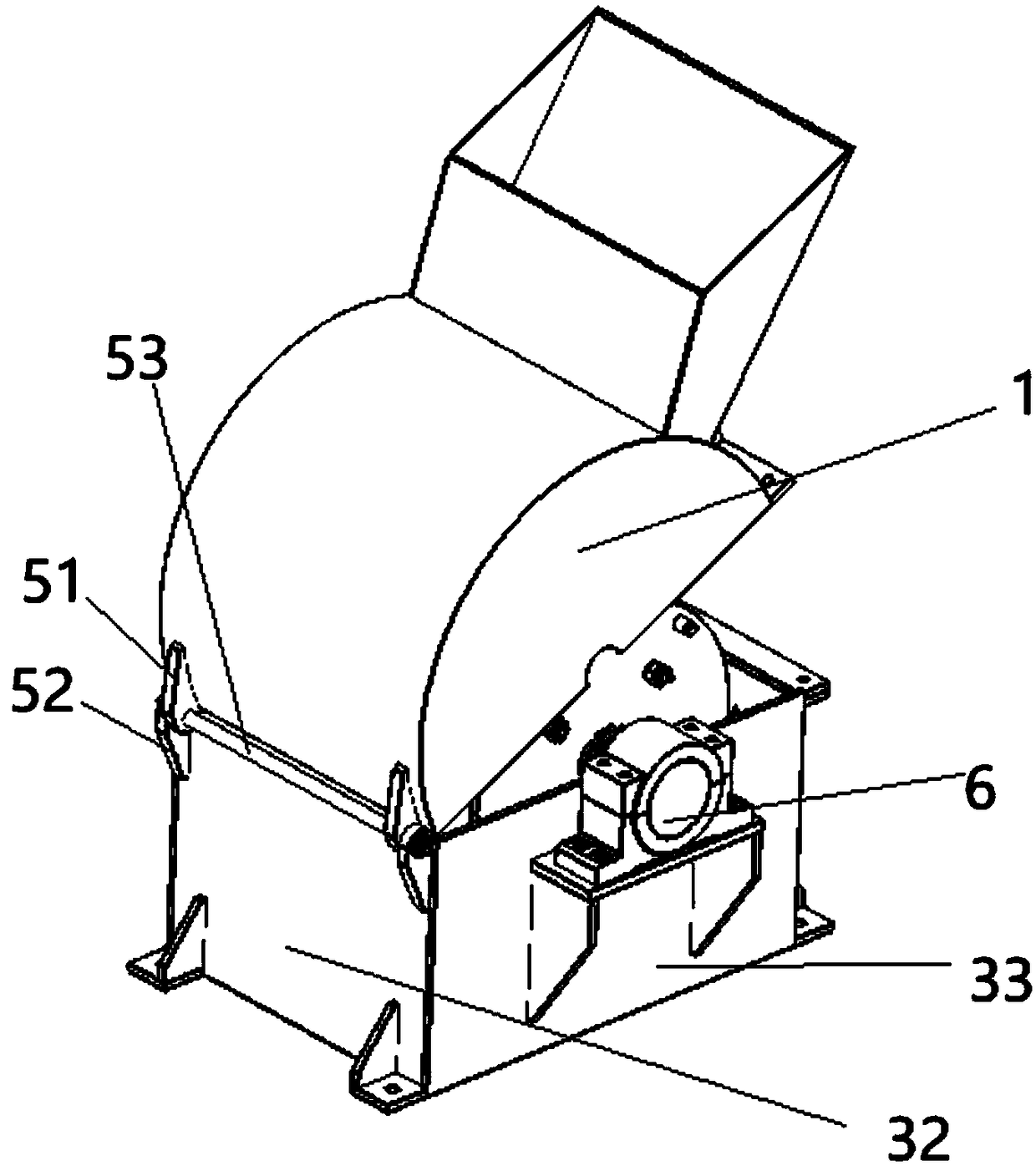

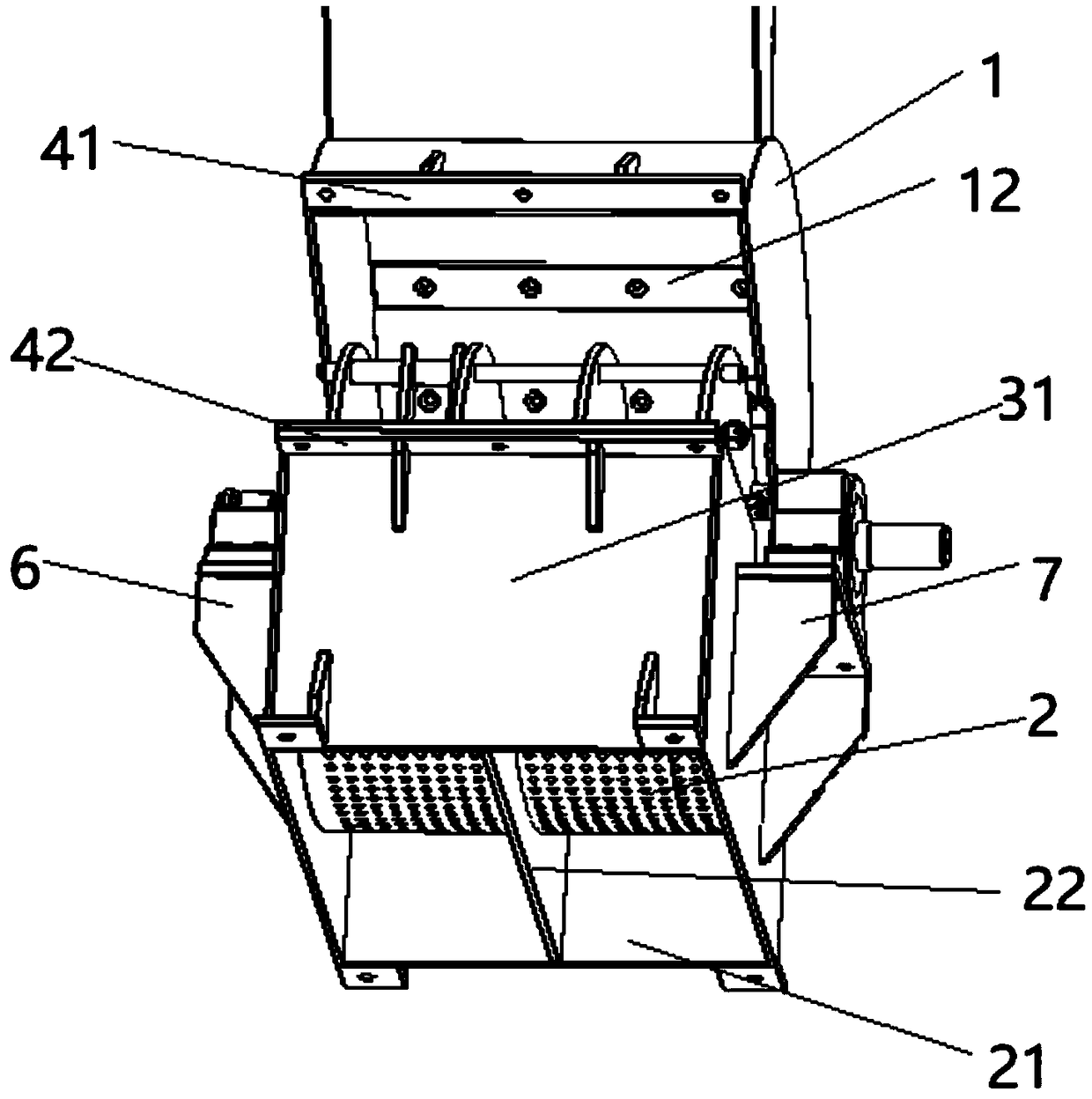

[0021] See Figure 1 to Figure 5 , The small-sized feed grinder of the present invention includes a shell, the shell includes an upper shell 1 and a lower shell 2, the upper shell 1 is connected with a feed inlet 11, and the inner side of the upper shell 1 is fixed with a lining Plate 12, several lining plates 12 are spaced at the same distance, and are fixed to the inner side of the upper shell 1 by first bolts, the lower shell 2 is a mesh arc-shaped hollow plate, the bottom of the lower shell 2 is a discharge port 21, and the lower shell 2 A fixed bracket 22 is provided at the bottom of the device. The lower shell 2 is surrounded by square side panels. The square side panels include a front side panel 31, a rear side panel 32, a left side panel 33, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com