Special new material rubber shock absorber and preparation method thereof

A new material and technology of shock-absorbing pads, applied in the field of building materials, can solve the problems of shortening the service life of rubber shock-absorbing pads, low tear strength of rubber pads, and easy damage to the interface, so as to achieve higher strength, less combustion, and fewer accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

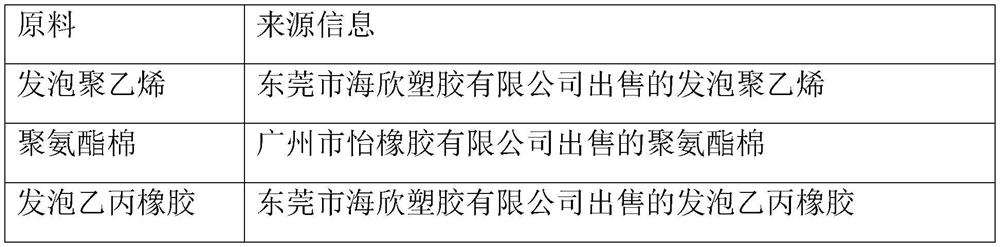

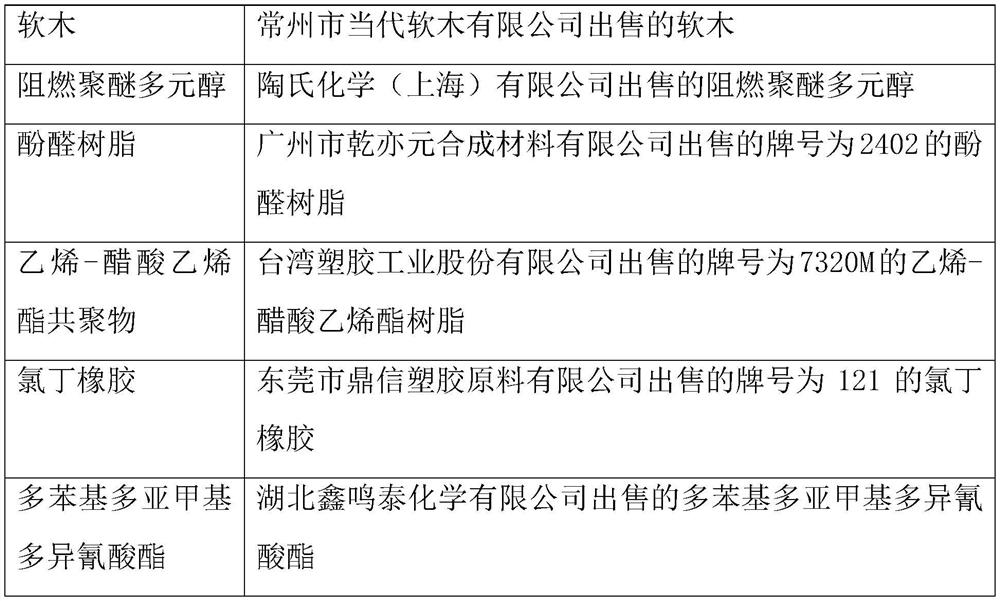

[0074] This application discloses a special new material rubber shock absorber, which includes the following components:

[0075] Foamed polyethylene, polyurethane cotton, foamed ethylene propylene rubber, cork, adhesives.

[0076] Adhesives consist of the following components:

[0077] Polyphenyl polymethylene polyisocyanate, polyether polyol, phenolic resin, organotin catalyst, organic solvent, ethylene-vinyl acetate copolymer, ethoxyquinoline, N,N-bis(2-hydroxyethyl )-2-nitro-p-phenylenediamine.

[0078] Polyether polyol is flame retardant polyether polyol;

[0079] The organotin catalyst is a compound of dibutyltin dilaurate and monobutyltin oxide;

[0080] The organic solvent is dichloromethane.

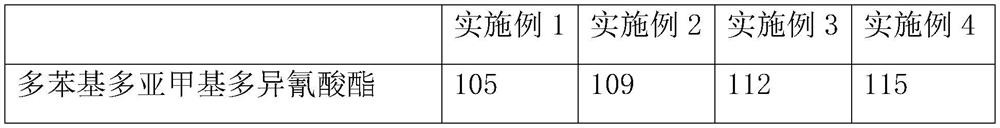

[0081] In embodiment 1-4, the input amount (unit Kg) of each component of adhesive is shown in Table 2 for details

[0082] Table 2

[0083]

[0084]

[0085] In embodiment 1-4, the input amount (unit Kg) of each component of special new material rubber damping pad s...

Embodiment 5

[0095] The embodiment of this application discloses a kind of adhesive:

[0096] Compared with embodiment 2, the difference only lies in:

[0097] Step 1), phenolic resin, ethylene-vinyl acetate copolymer and N, N-bis(2-hydroxyethyl)-2-nitro-p-phenylenediamine are added together with 40% dichloromethane into the first stirred tank , add flame retardant polyether polyol to the dichloromethane solution of phenolic resin, ethylene-vinyl acetate copolymer and N, N-bis(2-hydroxyethyl)-2-nitro-p-phenylenediamine, 100r / min, stirred for 15min, stirred evenly, and obtained the first mixture;

[0098] Step 2), polyphenyl polymethylene polyisocyanate and ethoxyquinoline are added to the second stirred tank together with the remaining dichloromethane, 100r / min, stirred for 10min, and stirred evenly to obtain the second mixture;

[0099] Step 3), adding the second mixture to the first mixture, stirring at 100r / min for 4min, and removing 80% of the volatilized dichloromethane under a pre...

Embodiment 6

[0102] The embodiment of this application discloses a kind of adhesive:

[0103] Compared with embodiment 2, the difference only lies in:

[0104] Step 1), phenolic resin, ethylene-vinyl acetate copolymer and N, N-bis(2-hydroxyethyl)-2-nitro-p-phenylenediamine are added together with 70% dichloromethane into the first stirred tank , add flame retardant polyether polyol to the dichloromethane solution of phenolic resin, ethylene-vinyl acetate copolymer and N, N-bis(2-hydroxyethyl)-2-nitro-p-phenylenediamine, 100r / min, stirred for 25min, stirred evenly, and obtained the first mixture;

[0105] Step 2), polyphenyl polymethylene polyisocyanate and ethoxyquin and the remaining dichloromethane are added to the second stirred tank, 100r / min, stirred for 20min, stirred evenly, to obtain the second mixture;

[0106] Step 3), adding the second mixture into the first mixture, stirring at 100r / min for 7min, and removing 90% of the volatilized dichloromethane under a pressure of 0.2MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com