Composite aluminum material for high-speed rail sound-insulating honeycomb panels produced by cold-rolling composite method and manufacturing method thereof

A manufacturing method and composite aluminum technology, applied in chemical instruments and methods, railway car bodies, layered products, etc., can solve the problems of uneven coating rate of finished products, low production yield, high production energy consumption, etc., and achieve shock absorption Good sound insulation effect, good support, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

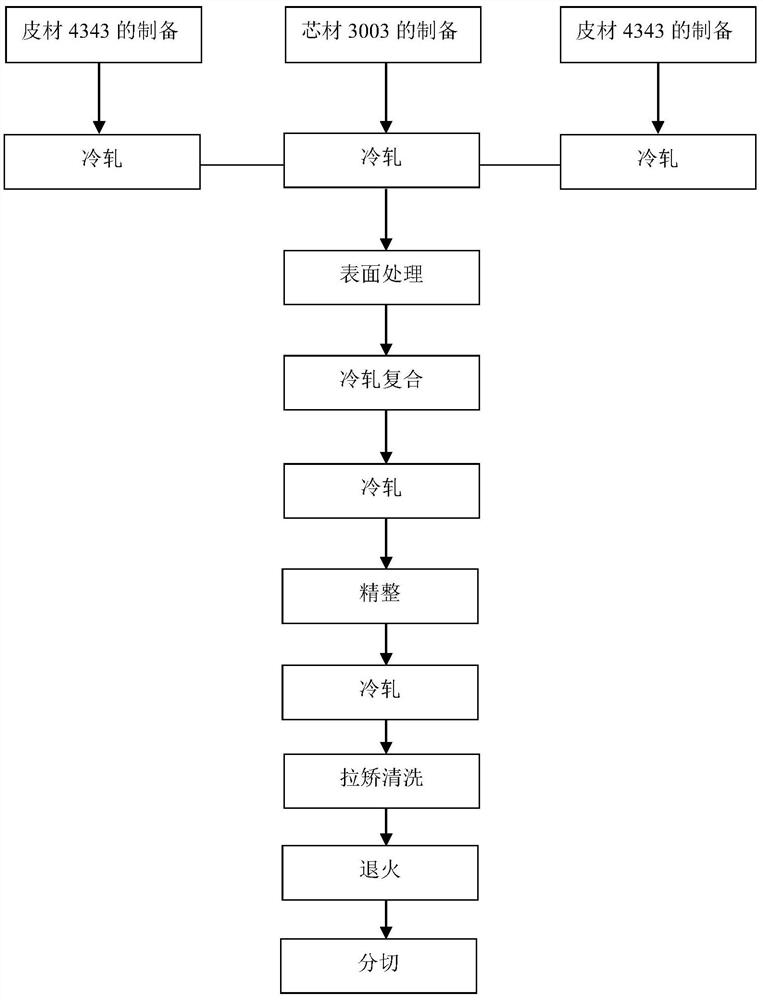

Method used

Image

Examples

Embodiment 1

[0053] The steps of preparing the composite aluminum material for the high-speed rail sound-insulating honeycomb panel produced by the cold composite method are as follows:

[0054] 1. Si 0.7%, Fe 0.6%, Cu 0.18%, Mn 1.3%, Mg 0.083%, Zn 1.3%, Zr 0.1, Ti 0.02% by weight, and the balance is Al as the basic component to prepare the alloy The raw material is smelted and cast-rolled by core material billet to obtain 7.0mm cast-rolled coil, alloy "3003";

[0055] According to the proportion of Si 7.2%, Fe 0.5%, Cu 0.1%, Mn 0.05%, Zn 0.1, and the balance is Al as the basic composition, the alloy raw materials are prepared for smelting and casting of skin material blanks to obtain 7.5mm cast-rolled coils, Alloy "4343";

[0056] 2. Core material preparation: Roughly roll the 3003 cast-rolled parent coil to a thickness of 4.0mm by 7.0-5.4-4.0, perform intermediate annealing for 2 hours, heat up to 240°C for 3h, continue to heat up to 520°C for 3h, and cool out of the furnace. Width 128...

Embodiment 2

[0066] The steps of preparing the composite aluminum material for the high-speed rail sound-insulating honeycomb panel produced by the cold composite method are as follows:

[0067] 1. By weight percentage Si 0.45%, Fe 0.5%, Cu 0.12%, Mn 1.4%, Mg 0.05%, Zn 1.8%, Zr 0.01%, Ti≤0.05%, the balance is Al as the basic component, Prepare alloy raw materials for core material billet smelting and casting to obtain 7.0mm cast and rolled coils, alloy "3003";

[0068] According to the proportion of Si 7.2%, Fe 0.5%, Cu 0.1%, Mn 0.05%, Zn 0.1, and the balance is Al as the basic composition, the alloy raw materials are prepared for smelting and casting of skin material blanks to obtain 7.5mm cast-rolled coils, Alloy "4343";

[0069] 2. Core material preparation: Roughly roll the 3003 cast-rolled parent coil to a thickness of 4.0mm by 7.0-5.4-4.0, perform intermediate annealing for 2 hours, heat up to 240°C for 3h, continue to heat up to 520°C for 3h, and cool out of the furnace. Width 128...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com