Experimental apparatus capable of automatically loading full section of rock

A loading experiment, a full-section technology, applied in the direction of measuring devices, transportation and packaging, using repeated force/pulsation force to test the strength of materials, etc., can solve the problem of loading that cannot simulate dynamic and static loads of rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

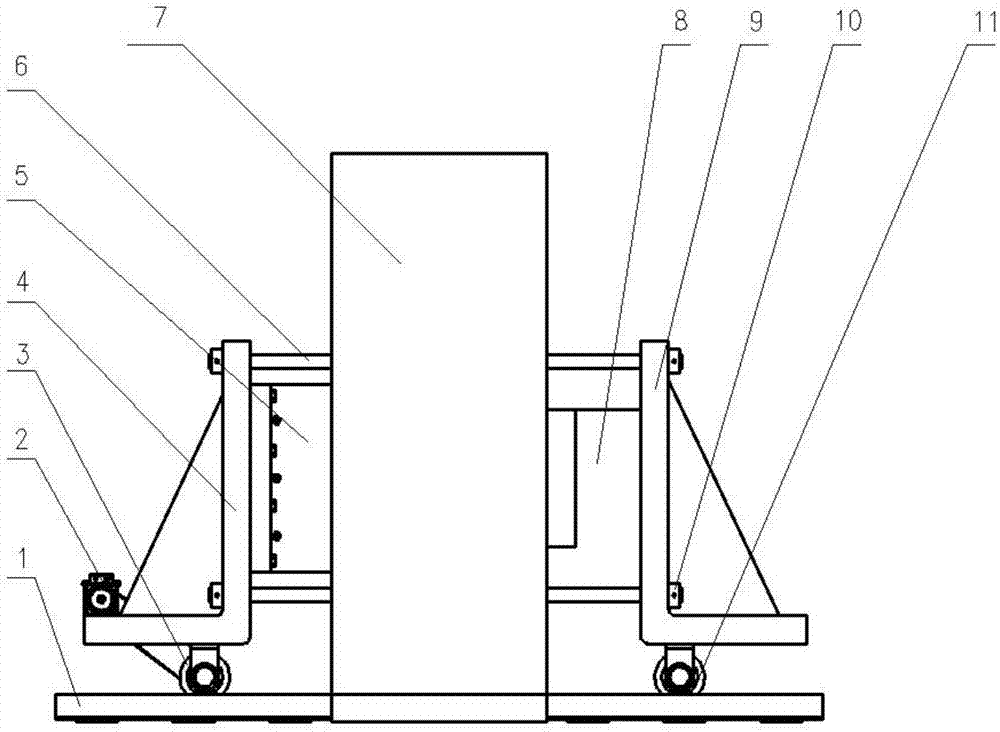

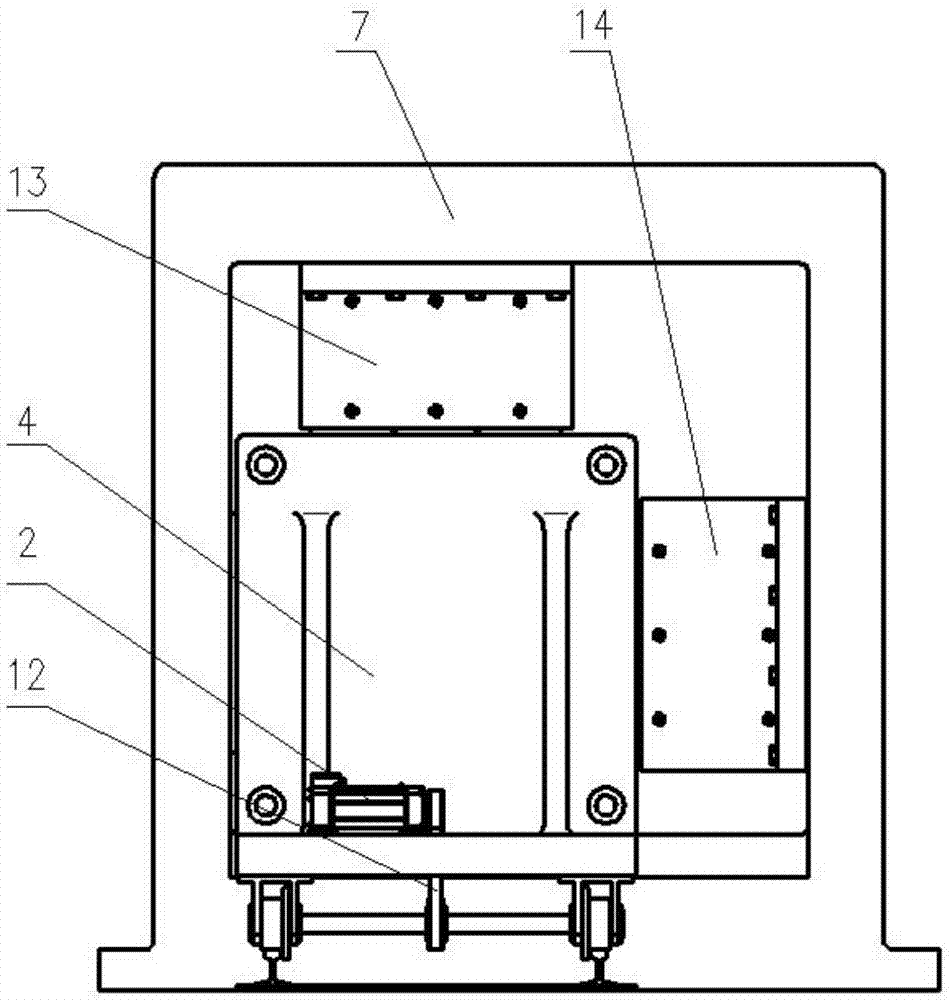

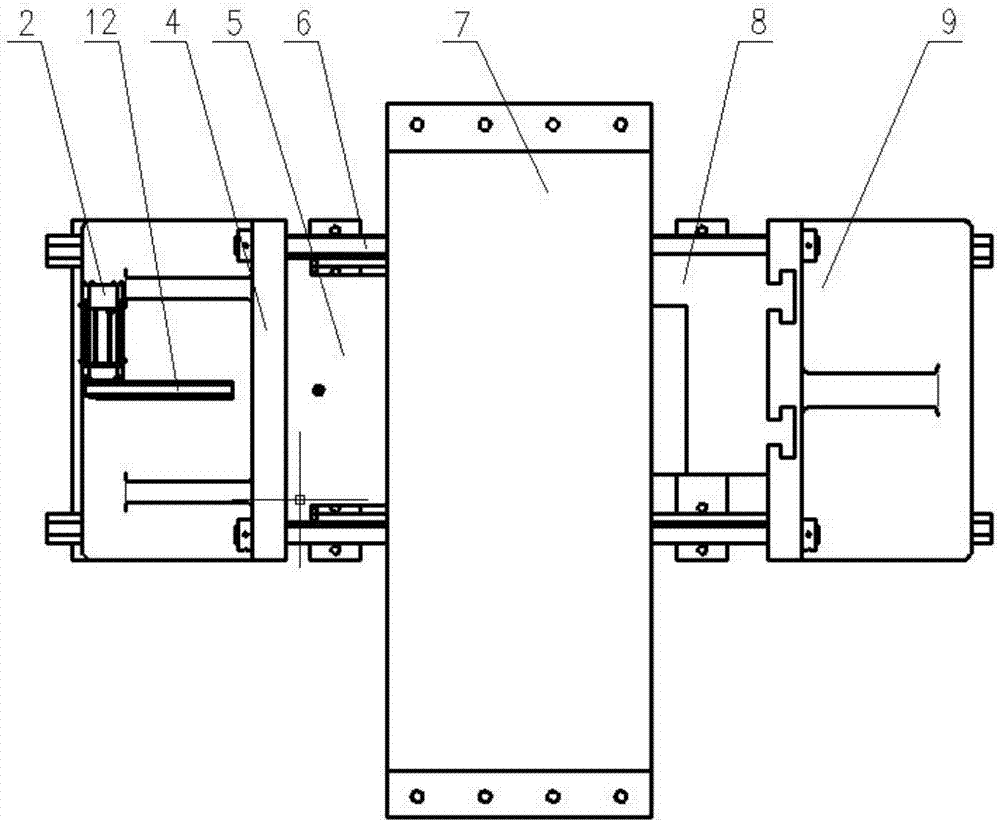

[0024] An automatic loading experiment device for full-section rocks, including three parts: a frame-type feeding structure, a fixed outer frame 7, and an adaptive elastic roller structure. Among them, the frame-type feeding structure is located inside the fixed outer frame 7, and the frame-type feeding structure includes: motor 2, motor fixing plate 4, driven fixing plate 9, feeding plate 8, connecting rod 6, synchronous belt drive 12 , driving wheel 3 and driven wheel 11. The section of the motor fixing plate 4 and the driven fixing plate 9 is “L” shape, one side is parallel to the ground, the other side is perpendicular to the ground, and a rib plate is erected on the side where the two sides are close; the motor fixing plate 4 is symmetrical to the driven fixing plate 9 Placement, the motor fixed plate 4 is connected to the vertical side of the driven fixed plate 9 by a connecting rod 6; connecting rod 6 ends are provided with connecting rod fastening devices 10.

[0025]...

Embodiment 2

[0030] combine Figure 1-Figure 8 As shown, a full-section automatic rock loading experiment device for geomechanics simulation experiments is designed to design a combined dynamic and static loading experiment device for rocks in three directions, including a fixed outer frame 7, side hydraulic cylinders 14 , top hydraulic cylinder group 13, horizontal hydraulic cylinder group 5, feeding track 1, frame type feeding structure and self-adaptive elastic roller structure; described side hydraulic cylinder group 14 and top hydraulic cylinder group 13 are fixed on the fixed outer frame 7. The horizontal hydraulic cylinder group 5 is connected and fixed to the frame-type feeding structure; wherein the frame-type feeding structure includes a motor 2, a motor fixing plate 4, a driven fixing plate 9, a feeding plate 8, a connecting rod 6, a connecting rod Rod fastening device 10, timing belt drive 12 and wheels. The close cooperation between the above-mentioned devices constitutes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com