Air handling equipment Water system

一种空气处理、设备的技术,应用在空气处理设备水系统领域,能够解决冷凝热没有得到有效利用、高品质的能源没有得到有效利用、设备初投资大等问题,达到结构简单、成本低廉、工作可靠的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

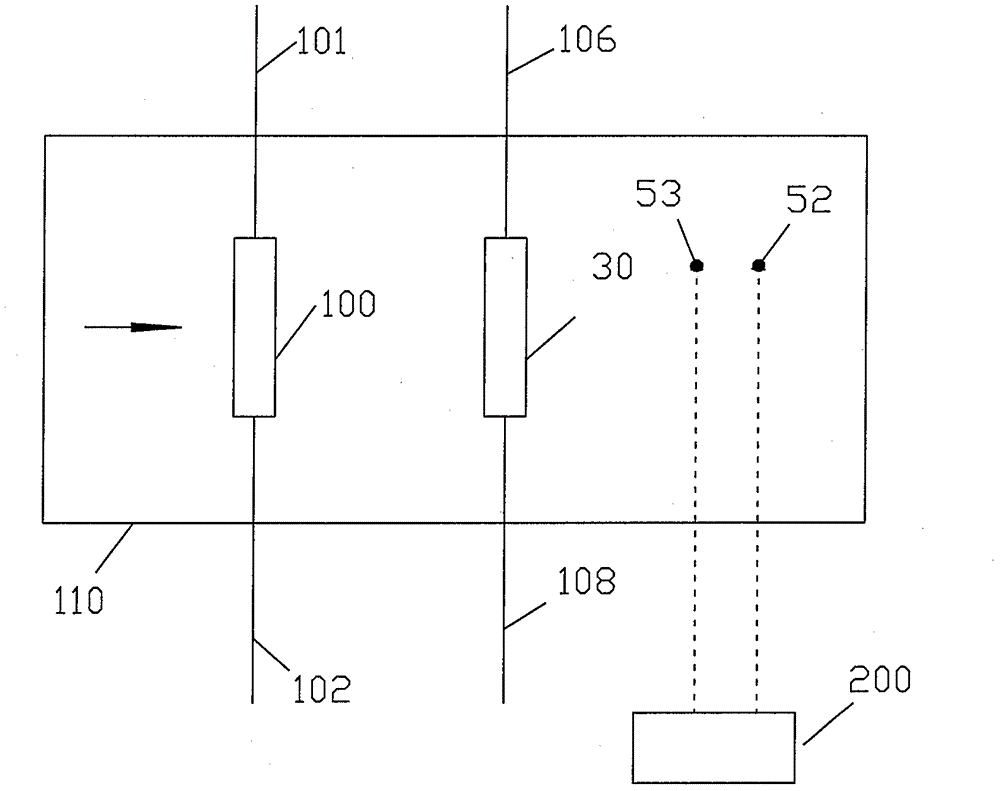

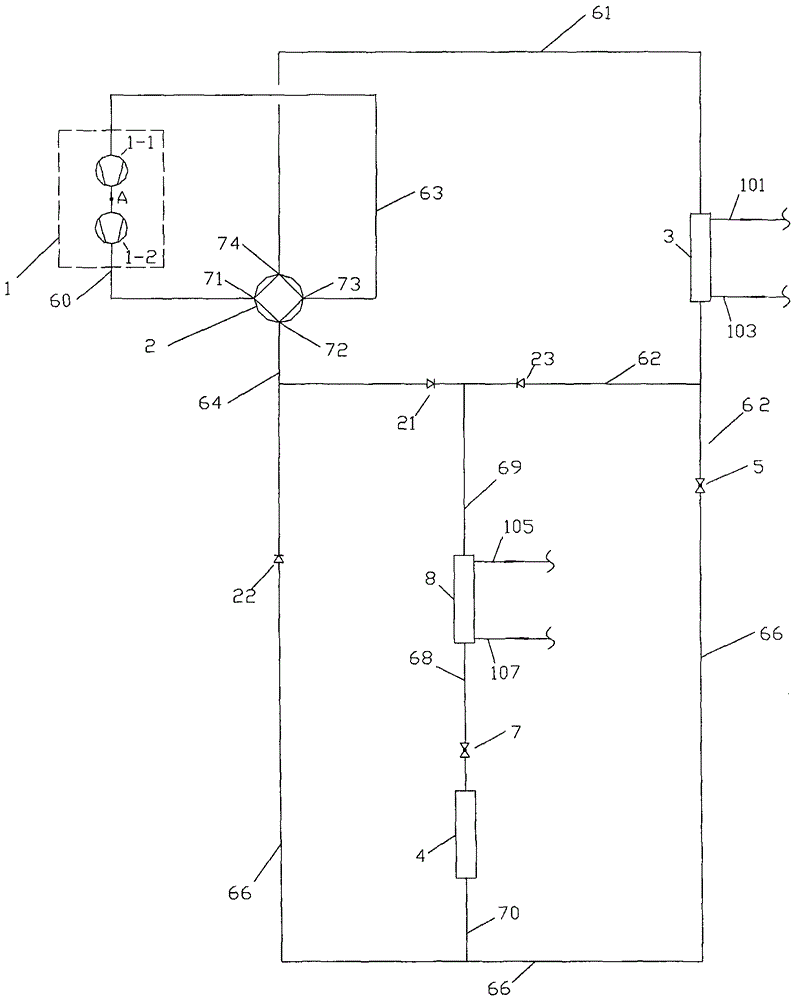

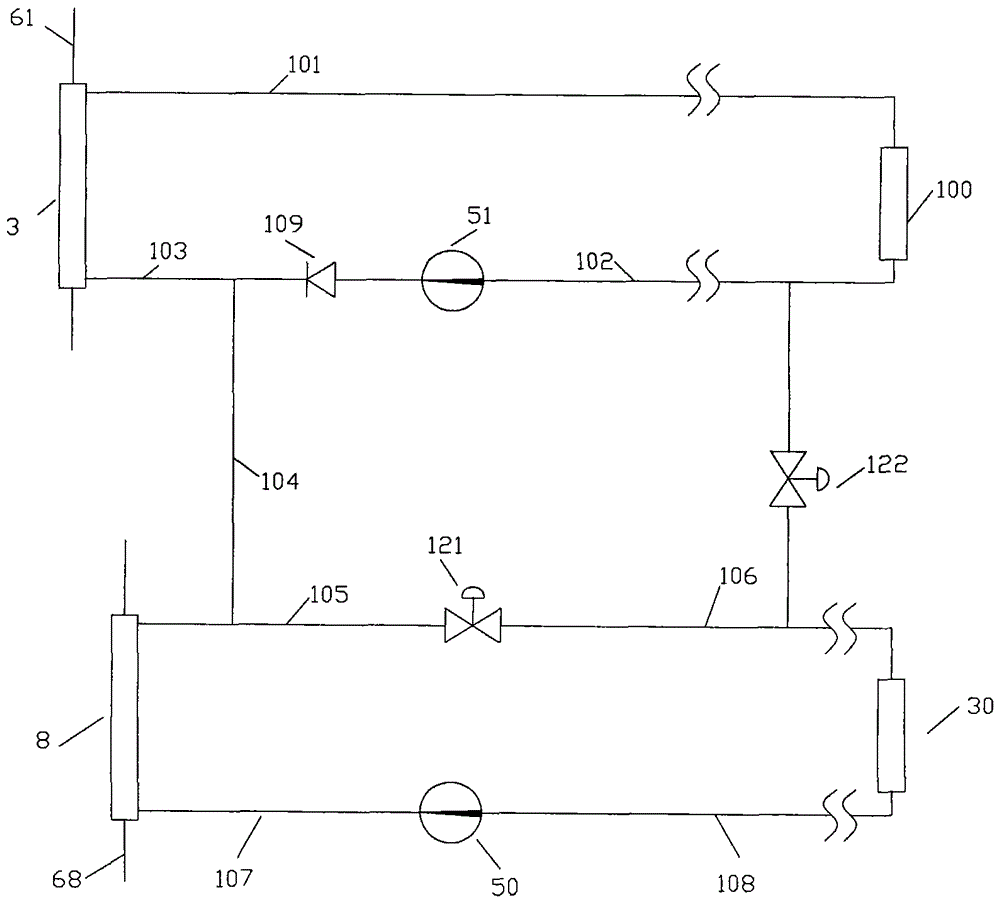

[0046] figure 2 The air treatment equipment water system shown includes the following components: user-side heat exchanger 3 of air-conditioning and refrigeration equipment, hot water heater 8 of air-conditioning and refrigeration equipment, reheater 30, hot water circulation pump 50, air-conditioning water circulation pump 51, Cooler 100 , check valve 109 , first water flow control valve 121 , second water flow control valve 122 .

[0047] this invention figure 2 The water system of the air handling plant shown, and the cooling and heating system for it during operation figure 1 The air-conditioning and refrigeration equipment shown can realize the following functions during the year-round operation. When realizing each function, figure 1 Shown air-conditioning and refrigeration equipment, and the matching of this embodiment figure 2 The working process of the water system of the air handling equipment shown is as follows.

[0048] (1) Separate production of chilled wa...

Embodiment 2

[0107] like image 3 As shown, it is the same as Example 1 figure 2 The difference of shown air treatment equipment water system is: present embodiment image 3 The air handling equipment water system shown has a fifth water flow control valve 125 and a bypass regulating valve 130 added to its air conditioning water subsystem.

[0108] The fifth water flow control valve 125 and the bypass regulating valve 130 are in image 3 The connection scheme in the water system of the air treatment equipment shown is: one end of the fifth water flow control valve 125 is connected to the outlet end of the cooler 100, and the other end of the fifth water flow control valve 125 is connected to the inlet of the air-conditioning water circulation pump 51 through the one hundred and second pipe 102 The inlet port of the bypass regulating valve 130 is connected with the one hundred and first pipe 101 between the water side outlet port of the user-side heat exchanger 3 and the inlet port of th...

Embodiment 3

[0157] like Figure 5 As shown, it is the same as Example 1 figure 2 The difference of shown air treatment equipment water system is: present embodiment Figure 5 The air handling equipment water system shown has a three-way flow regulating valve 140 added to its air conditioning water subsystem.

[0158] The three-way flow regulating valve 140 is in Figure 5 The connection scheme of the water system of the air treatment equipment shown is: the direct connection point E of the three-way flow regulating valve 140 is connected to the outlet of the cooler 100, and the confluence connection point B of the three-way flow regulating valve 140 passes through the one hundred and second pipeline 102 It is connected to the inlet of the air-conditioning water circulation pump 51, and the bypass connection point F of the three-way flow regulating valve 140 is connected to the one hundred and first pipe 101 between the water side outlet of the user-side heat exchanger 3 and the inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com