Suspension subframe

一种悬架系统、副车架的技术,应用在副车架领域,能够解决板材冲压工序数量增大、副车架重量增加、制造复杂等问题,达到扩展自由度、提高作业性、提高安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

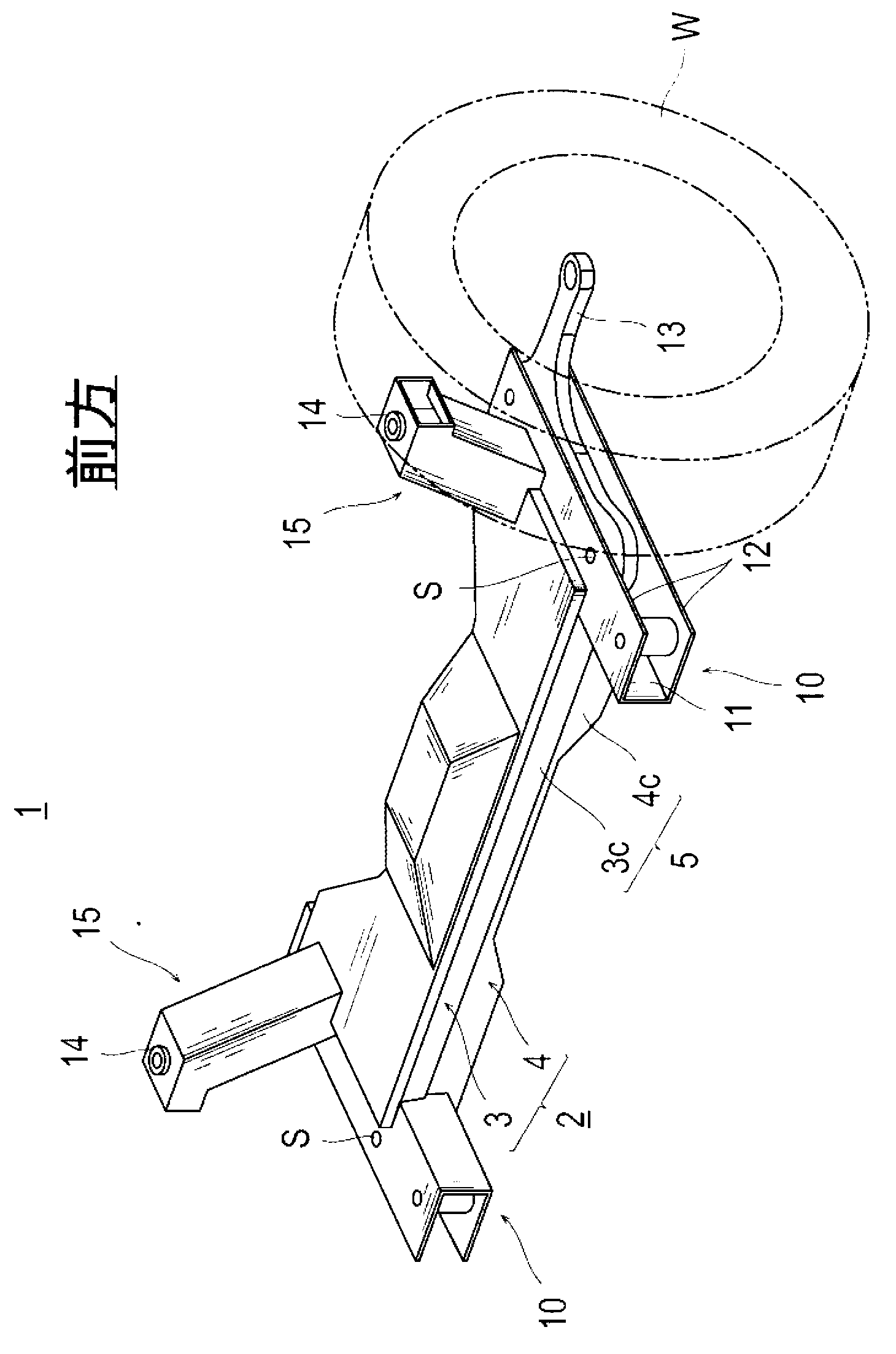

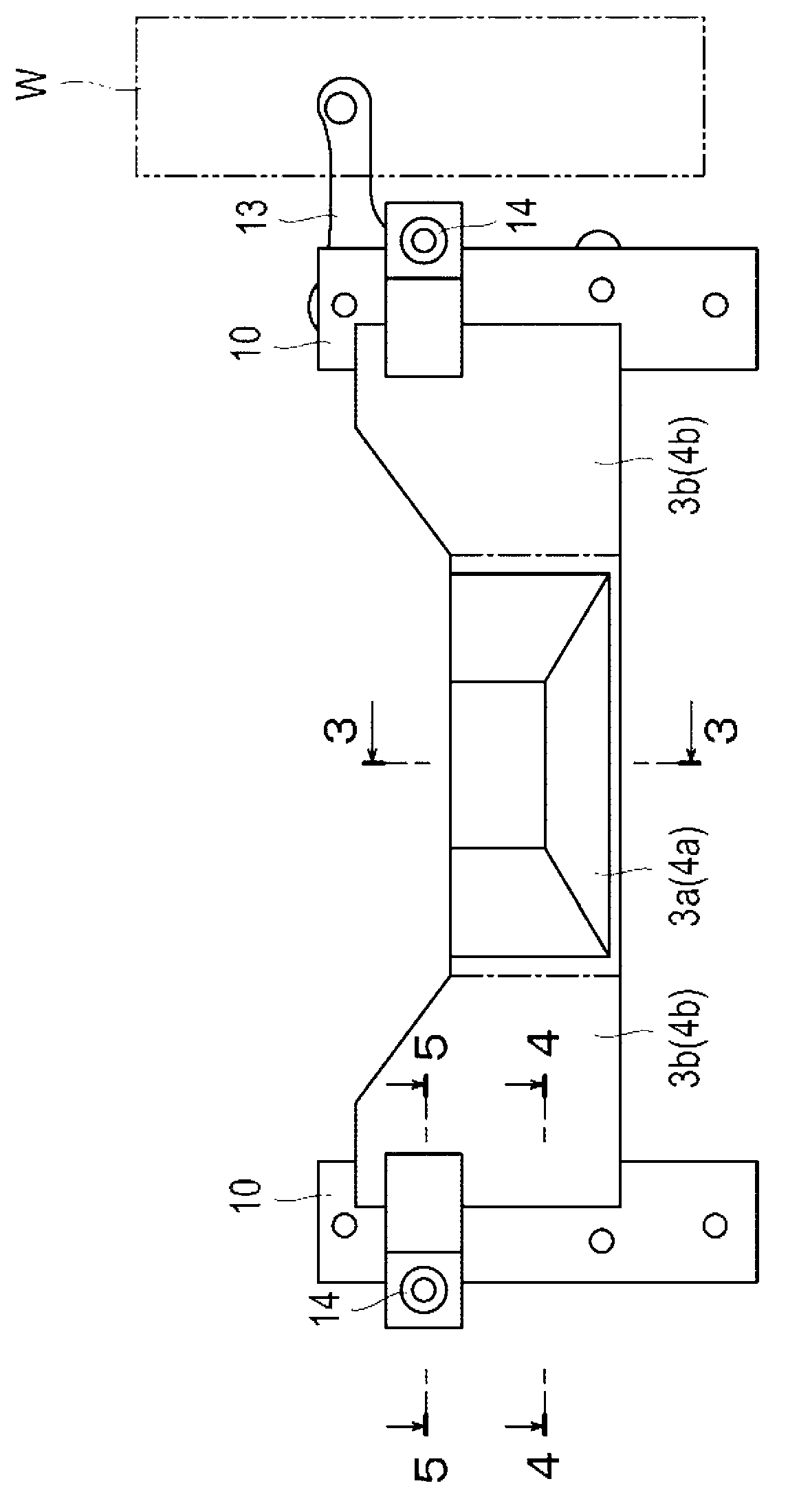

[0026] Embodiments of the present invention will be described in detail below.

[0027] exist figure 1 Among them, the subframe 1 of the suspension system of this embodiment is used for the front suspension, and is roughly composed of a main body member 2 with a relatively large area that is arranged between two wheels (only one wheel is shown in the figure) W. It is composed of side end members 10 respectively attached to both side end portions of the main body member 2 in the vehicle width direction. The main body member 2 and the side end member 10 are attached to the vehicle body through the connecting member 15, but instead of using such a connecting member 15 having a predetermined height in the vertical direction, they may be attached to the side of the vehicle body directly or through a height adjusting member or the like. .

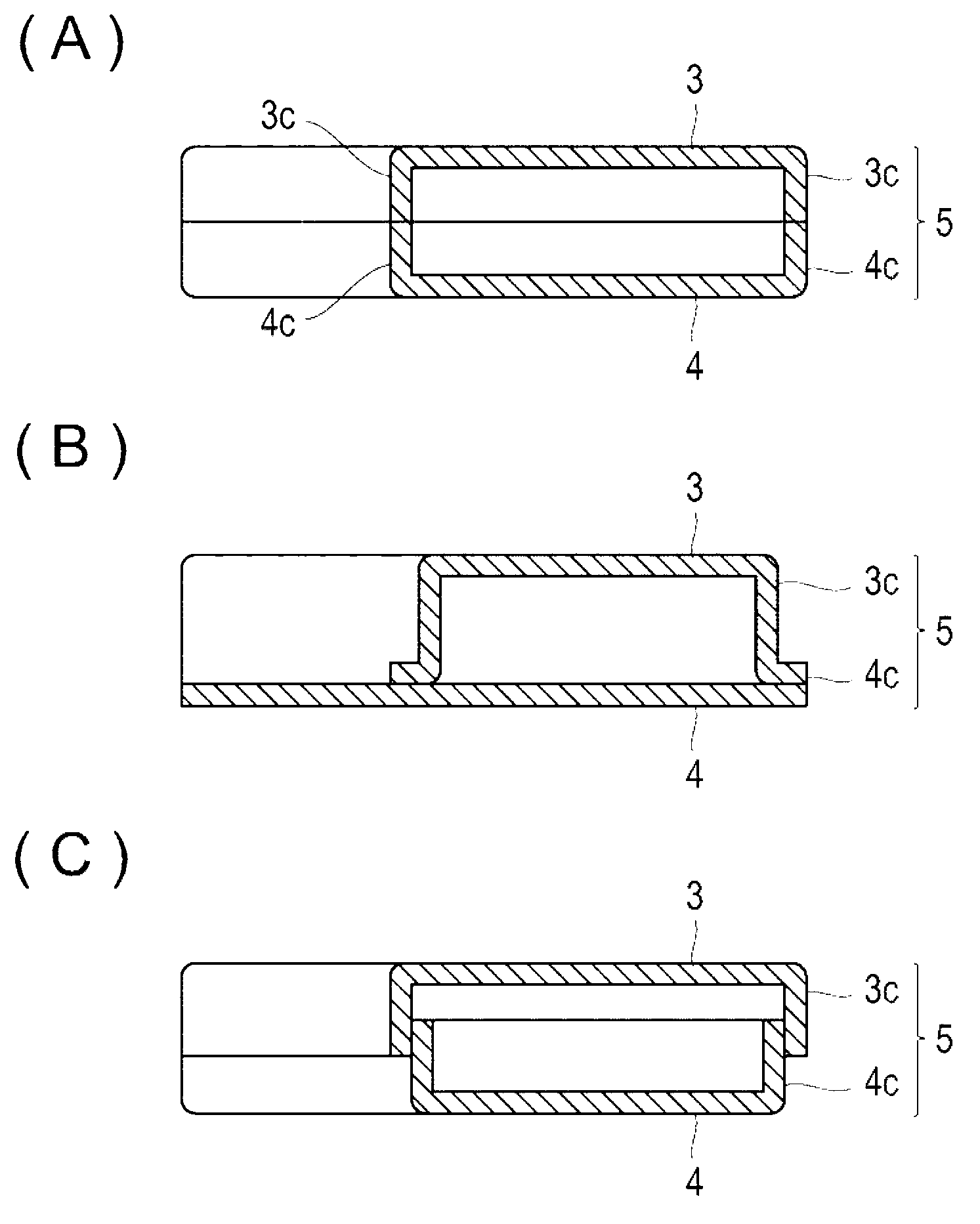

[0028] Further details are given below. First, if figure 1 , figure 2 As shown, the main body component 2 is substantially “I”-shaped in p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap